Composite track steel wire rope-driven coal mine patrol robot

A technology of inspection robots and steel wire ropes, applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., can solve the problems of low inspection efficiency and large time gap, achieve low power consumption, simplify mechanisms, and improve inspection The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiment of the present invention will be further described below in conjunction with accompanying drawing:

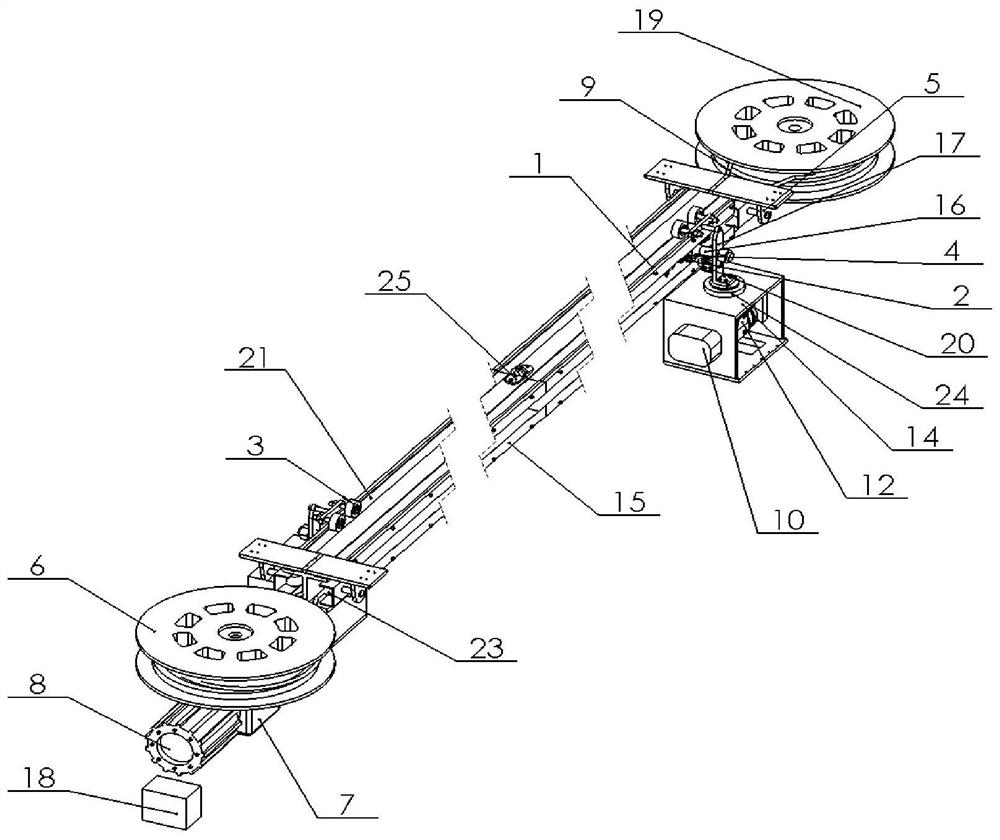

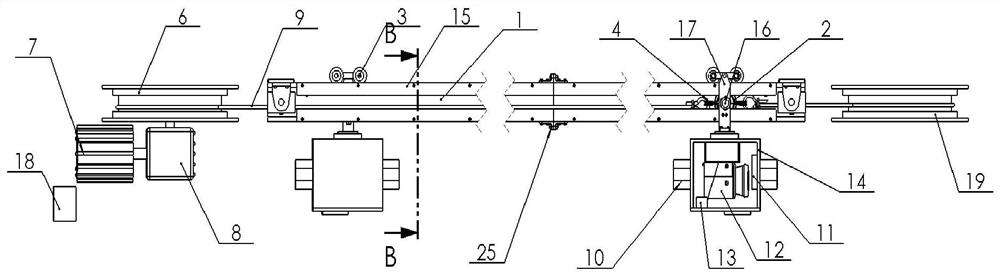

[0035] Such as figure 1 with figure 2 As shown, the composite track wire rope traction coal mine inspection robot of the present invention includes a track mechanism, a traveling mechanism, a driving module, a patrol module and a control unit, wherein two traveling mechanisms are respectively arranged on the track mechanism, and the driving module is arranged on the track On both sides of the mechanism, the inspection module is set on the traveling mechanism; the control unit is placed at one end of the track mechanism to receive and judge the information sent by the inspection module and control the start and stop of the entire system;

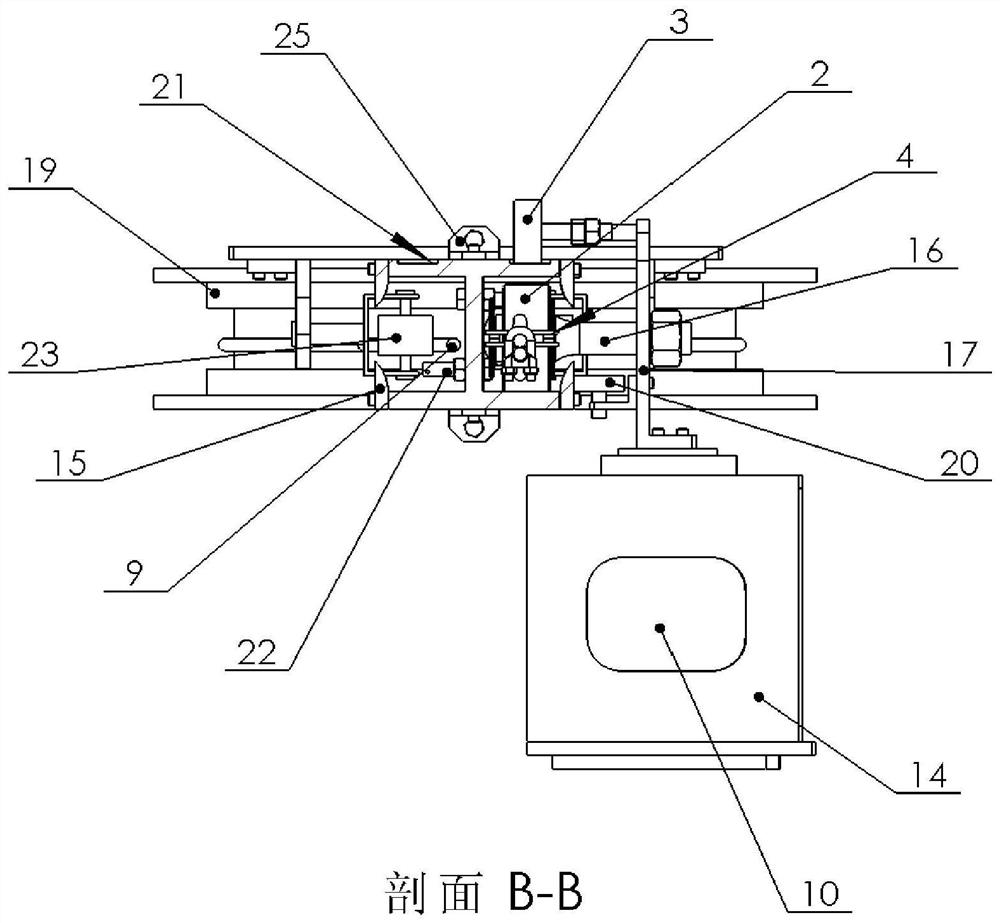

[0036] Such as image 3As shown, the track mechanism includes a track 1, a limit bolt 22, a protective plate 15, a rail connecting plate 25, and a rope pulley 23. The single track with direction opening, the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com