Relay base

A relay and base technology, applied in the field of relay bases, can solve the problems of waste control cabinet appearance, maintenance work interference, waste of artificial wires, etc., and achieve the effect of reducing repeated wiring, reducing waste, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

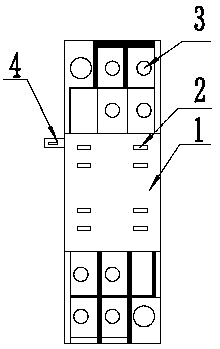

[0010] as attached figure 1 As shown, a relay base includes a base body 1 on which pin holes 2 and wire pressing holes 3 are provided.

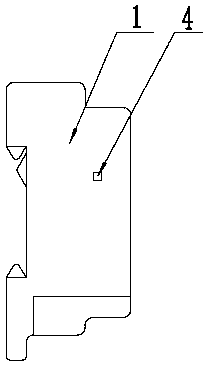

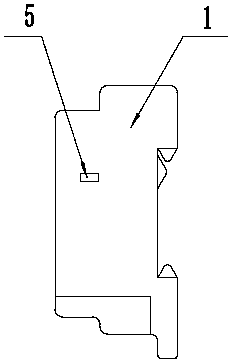

[0011] as attached figure 1 and attached figure 2 As shown, a common point plug 4 is provided on the left side of the seat body 1, as attached image 3 As shown, a common point jack 5 is provided on the right side of the seat body 1, and the common point plug 4 and the common point jack 5 are used as a group of common point connecting devices and one of the common point wires on the seat body 1 The pressure hole 3 is electrically connected.

[0012] When multiple relays are installed side by side, install the rightmost relay base first, and then install from the right to the left. The common point plug on each relay base is inserted into the common point jack of the adjacent relay base on its left in turn. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com