Annular sorting device and application method thereof

A technology of a sorting device and an application method, which is applied in the field of sorting devices and circular sorting devices, can solve problems such as limited sorting efficiency, complicated system control, and limited use, so as to improve sorting capacity and efficiency, and improve sorting efficiency. The effect of improving picking efficiency and increasing the position of ornaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

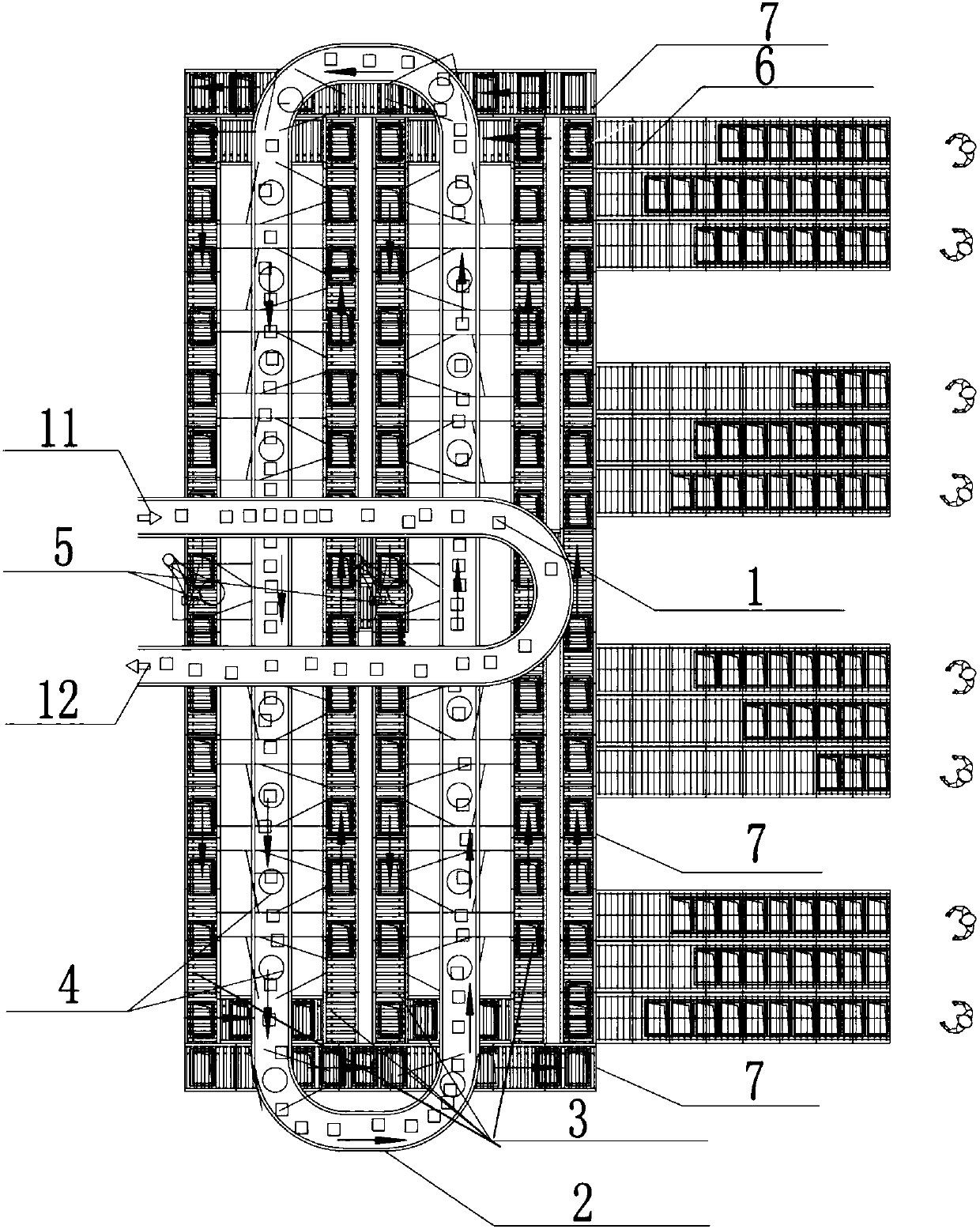

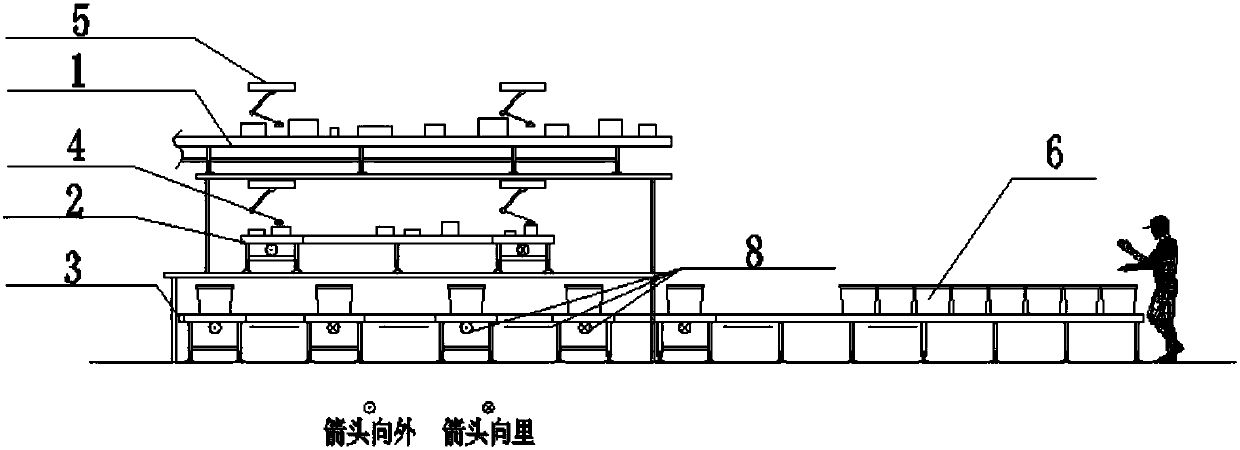

[0046] Such as Figure 1-2 As shown, a circular sorting device includes a first conveying loop 2 and a second conveying loop 3, the first conveying loop 2 and the second conveying loop 3 are arranged up and down, and the first conveying loop 2 is arranged on the second conveying loop 3 Above, the first conveying loop 2 is used to place commodities to be sorted, the second conveying loop 3 is provided with turnover containers, and a plurality of sorting robots 4 are arranged between the first conveying loop 2 and the second conveying loop 3 .

[0047] The first conveying loop line 2 includes two straight sides parallel to each other, and the two straight sides are connected by arc-shaped edges at the ends, so that the first conveying loop line 2 forms a racetrack-shaped loop line.

[0048] The inner and outer sides of the two straight sides of the first conveying loop 2 are provided with a second conveying loop 3 .

[0049] It also includes an inbound conveying line 1 for conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com