Elastic adjustable cooling frame for extruded plate

A technology of cooling frame and extruded board, which is applied in applications, household appliances, and other household appliances. It can solve the problems of low accuracy of extruded board and cooling frame does not have the adjustment function, so as to ensure accuracy and sameness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

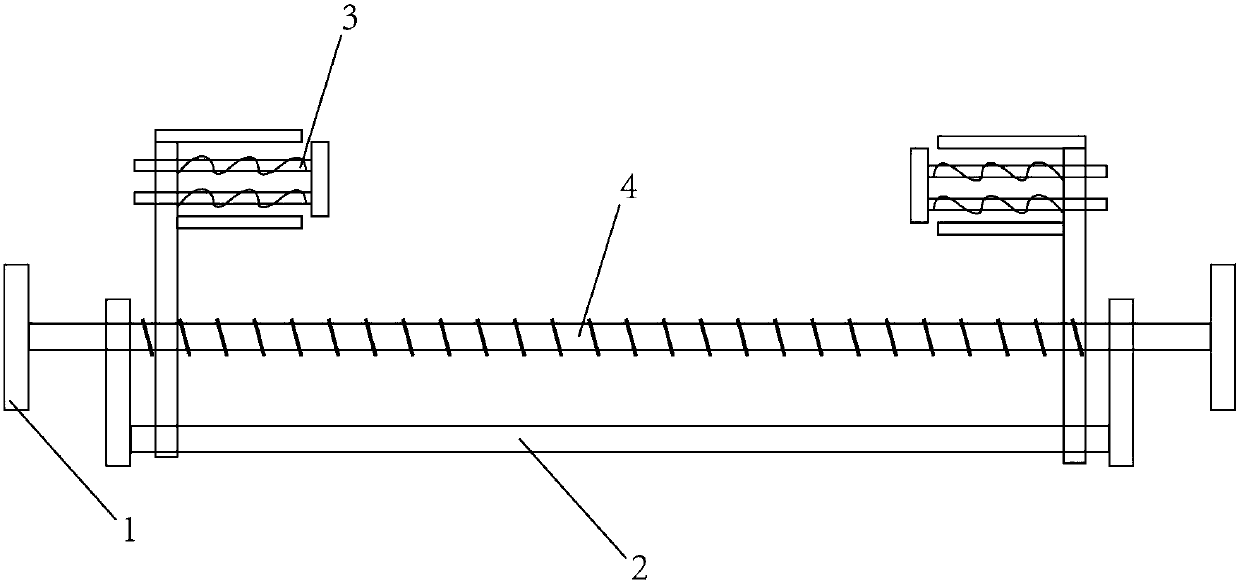

[0012] Example 1 : like figure 1 The elastically adjustable cooling frame for extruded boards shown includes a cooling frame body and elastic adjustment devices 3 located on both sides of the end of the cooling frame body. , the left and right spiral ladder screw rod 4 is fixed on the guide shaft 2, and the hand wheel 1 is connected with the left and right spiral ladder screw rod 4. The bracket is connected to the guide shaft 2, and the elastic adjustment setting includes a support rod and an elastic member arranged on the top of the support rod. The elastic parts are arranged facing each other, and the front end of the elastic part is provided with a blocking piece for limiting the position of the extruded plastic plate, and a spring is provided on the connecting rod between the blocking piece and the pole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com