Feeding track balance correction device for fully-automatic wastepaper packer

A waste paper baler and feeding track technology, which is applied in the directions of packaging and bundling machinery parts, etc., can solve the problems of shortening the service life of the slide rail, wear of the roller and the track, etc., and achieves the effect of simple and convenient operation and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

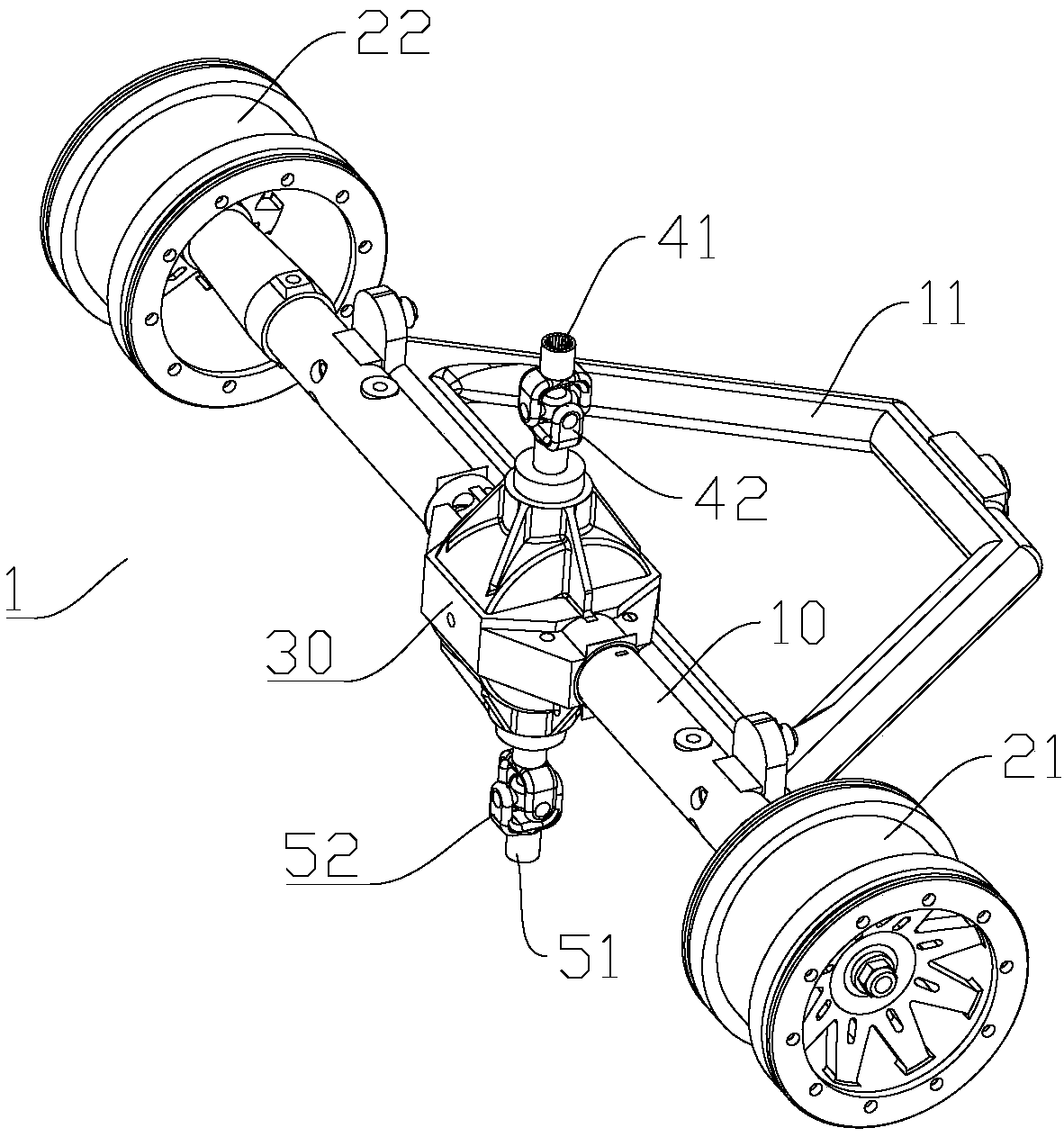

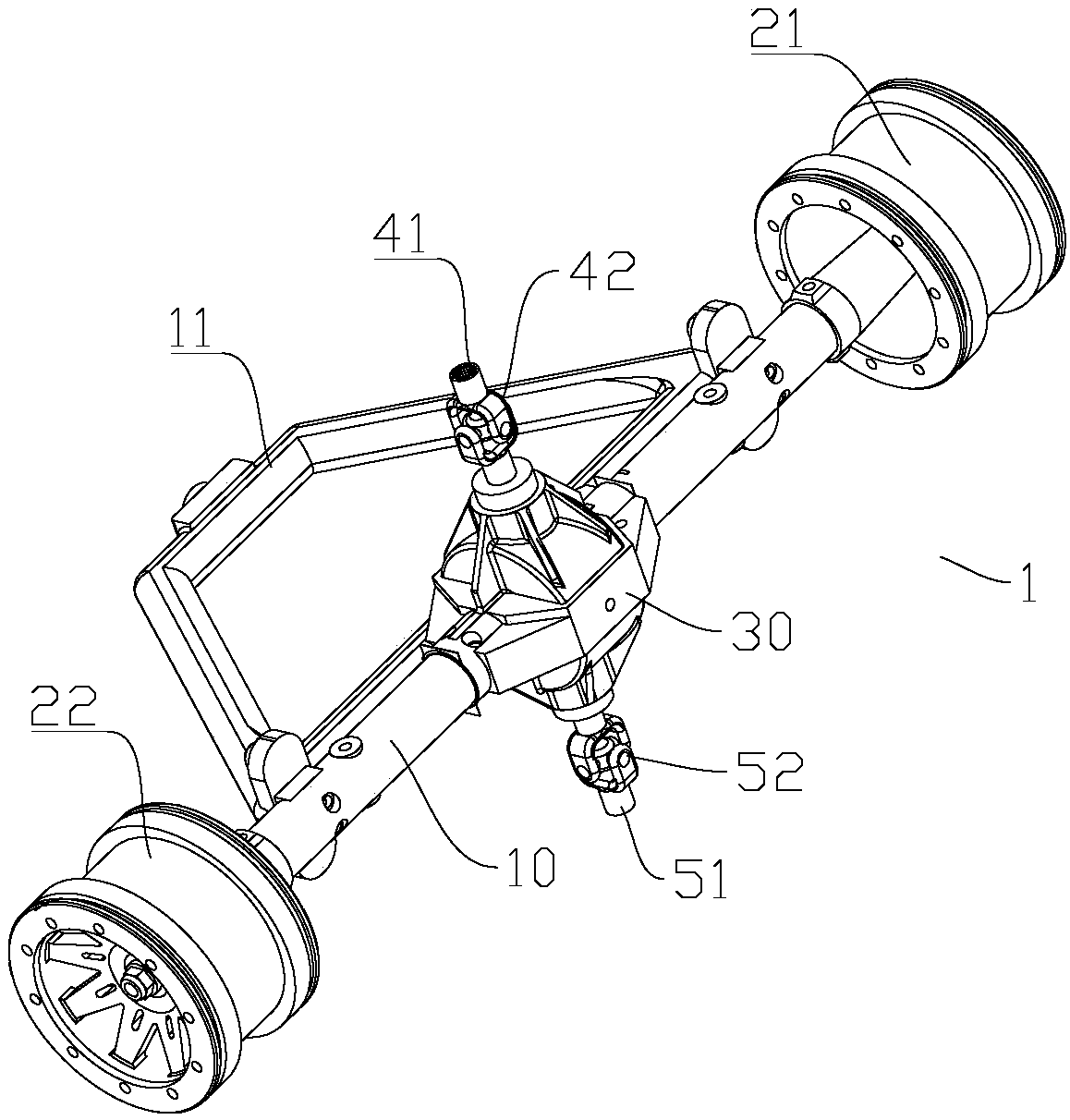

[0013] Such as figure 1 , figure 2 As shown, a full-automatic waste paper baler feeding track balance corrector 1 includes a beam 10 on which a calibration beam 11 is provided, and a first roller 21 and a first roller 21 are telescopically provided at both ends of the beam 10. Two rollers 22, a control box 30 is arranged in the middle of the beam 10, a width check rod 41 is provided on the control box 30, a width adjustment handle plug 42 is provided on the width check rod 41, and an inclination check rod 42 is also provided on the control box 30. The rod 51 and the inclination check rod 51 are provided with an inclination adjustment handle plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com