Grain transporting trolley

A technology for transporting trolleys and grains, applied in the directions of internal parts and external parts, etc., can solve the problems of low transportation efficiency, increased labor, single structure and function, etc., and achieve the effect of wide range of uses, labor saving, and transportation efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

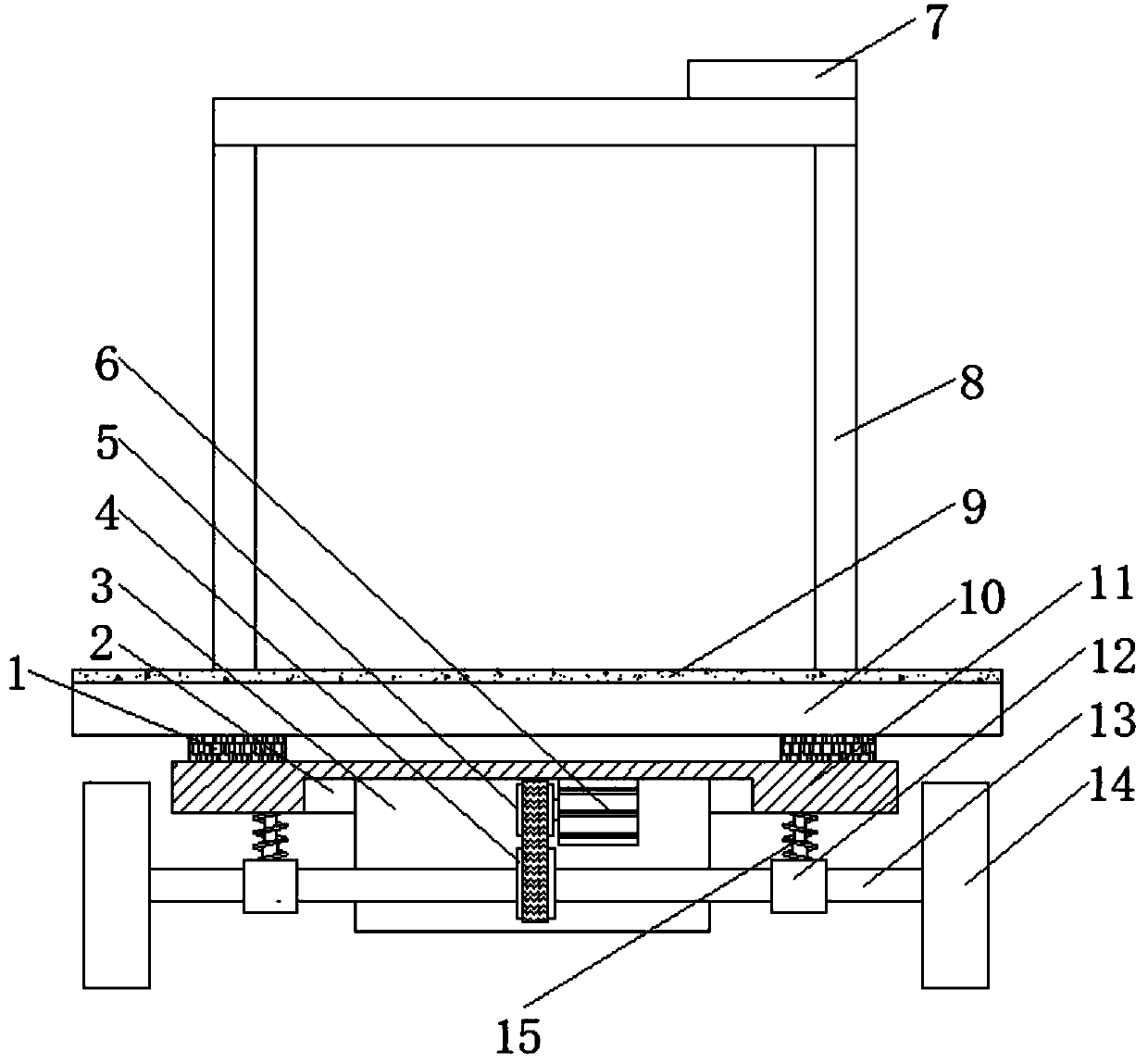

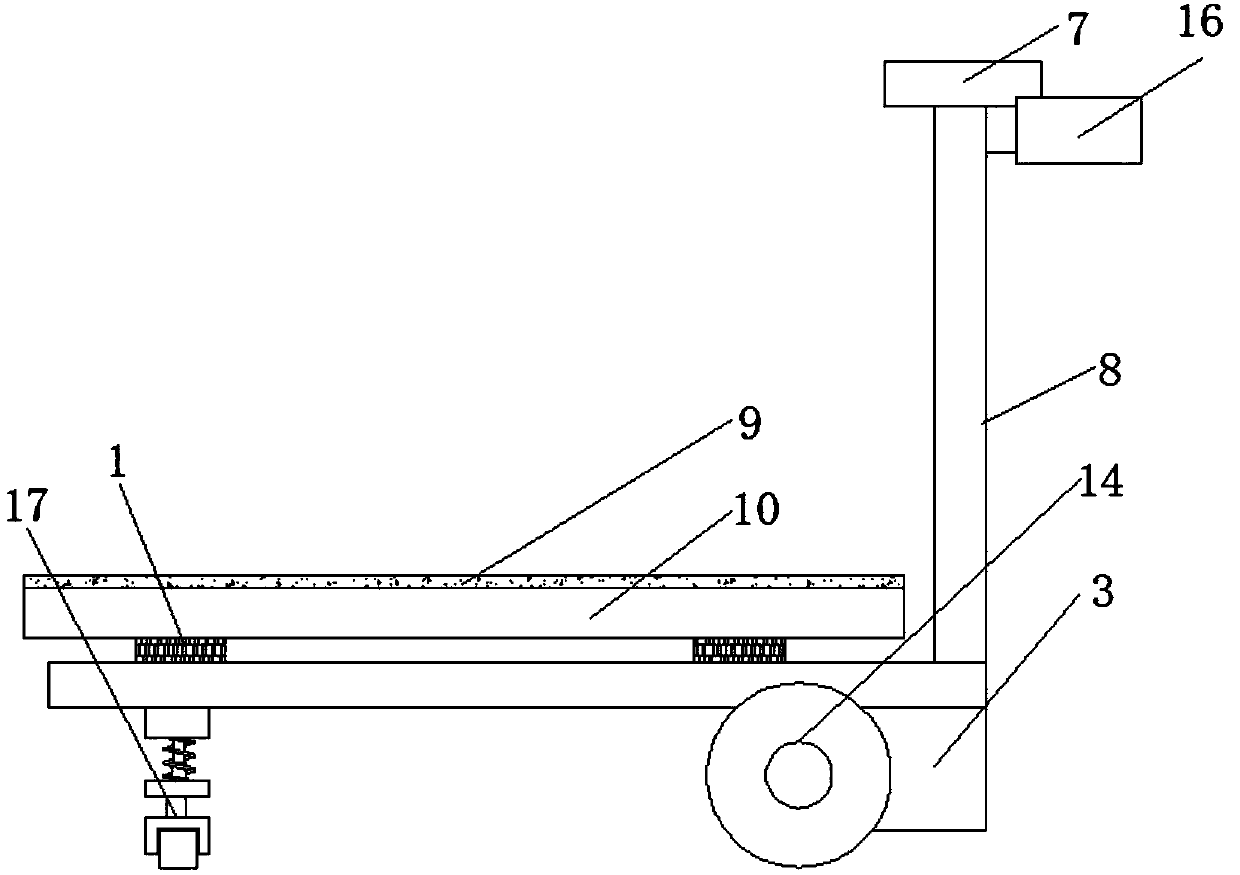

[0016] refer to Figure 1-2 , a grain transport trolley, comprising a car floor 11, a door frame 8 is welded on one side of the top of the car floor 11, and handles 16 are welded at both ends of the top of the side of the door frame 8 away from the car floor 11, and the door frame The center of the top of 8 is connected with control box 7 by bolts, and the bottom four corners of vehicle floor 11 are all connected with vertical shock absorbers 15 by bolts, and the bottoms of two shock absorbers 15 close to portal frame 8 are all connected by bolts. Bearing blocks 12 are connected, and the bottoms of the other two shock absorbers 15 are connected with universal wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com