Novel aluminum section

A new type of aluminum profile technology, applied in the direction of slender components, building components, etc., can solve the problems of impact on the service life of profiles, insufficient intermediate strength, shortened service life of aluminum profiles, etc., to avoid uneven local stress and strengthen strength , the effect of strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

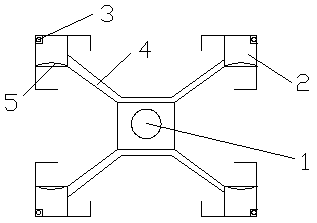

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] A new type of aluminum profile, the cavity 1 is provided with a connection groove 2, the connection groove 2 is distributed along the center of the cavity 1, and the reinforcement 3 is arranged on the connection groove 2, and the reinforcement 3 is arranged along the outside of the connection groove, and the reinforcement The part 3 is a fine hole structure, the reinforcement part 3 and the connection groove 2 are integrally formed, and the support part 4 is provided between the cavity 1 and the connection groove 2, and the support part 4 is in a cross-shaped structure, and the support part 4 is in contact with the cavity 1 The thickness of the outer wall and the inner wall of the cavity 1 is 10mm-20mm, preferably 12mm, the cavity 1 is a round hole structure, the cavity 1 is a front-to-back conduction structure, the reinforcement 3 is a strip-shaped pore structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com