Micro switch with heat dissipation structure

A technology of micro switch and heat dissipation structure, which is applied in the direction of electric switches, electrical components, circuits, etc., and can solve the problem of affecting the reliability of the connection between the conduction contact rod and the incoming terminal and outgoing terminal, affecting the normal function and applicability of the micro switch and practicability limitations, etc., to achieve the effects of arc extinguishing, improving stability and service life, and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

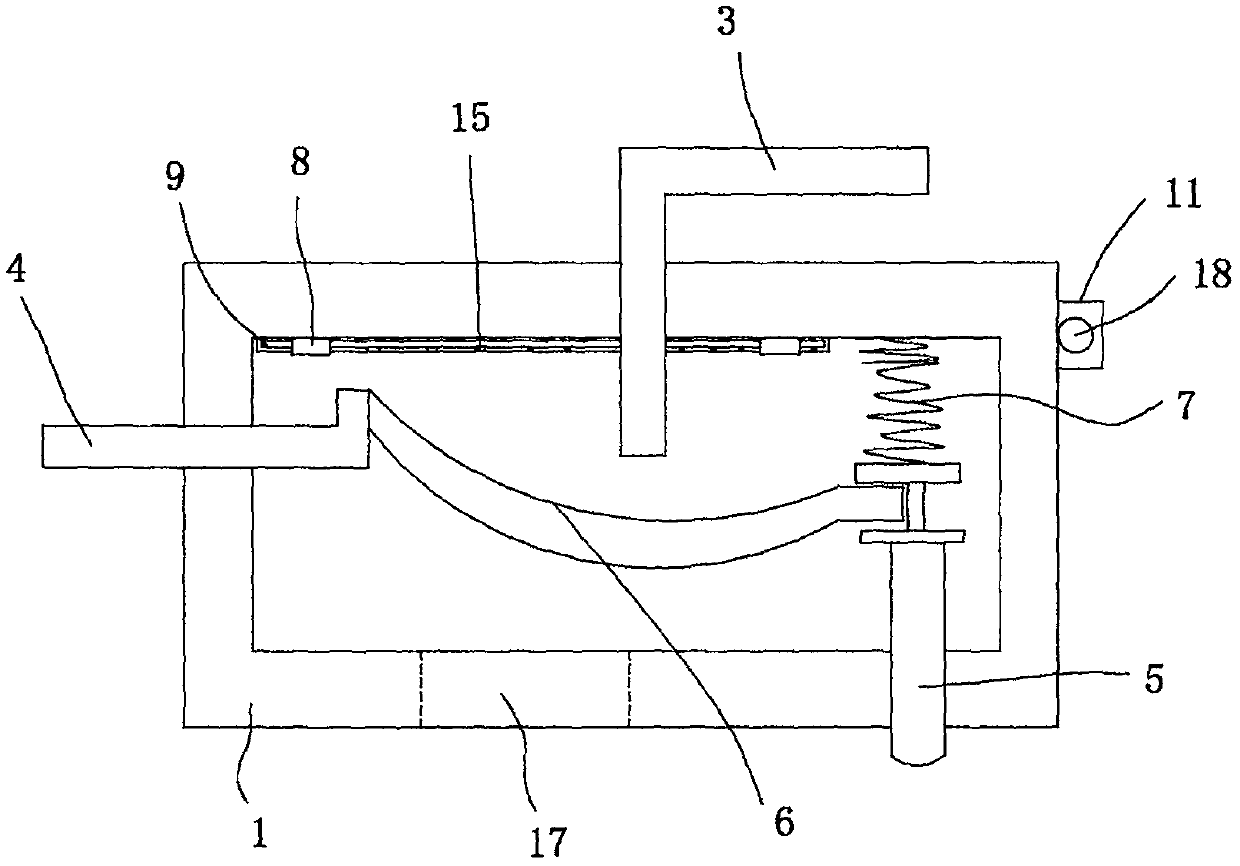

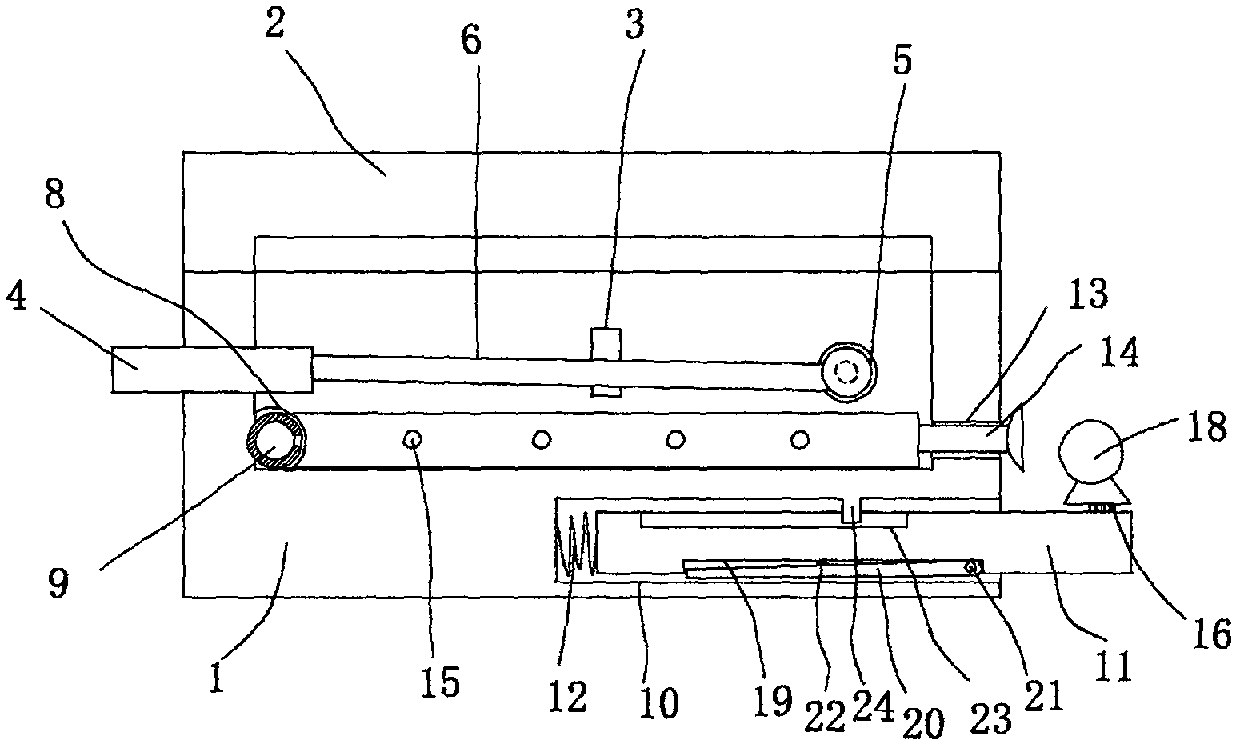

[0014] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a sectional structure diagram of the present invention.

[0015] See figure 1 and figure 2 , a micro switch with a heat dissipation structure, including a bottom case 1 and a cover 2, on which the bottom case 1 is provided with an incoming line terminal 3, an outgoing line terminal 4 and a button 5, and inside the bottom case 1 is provided with Conduction contact rod 6, there is a return spring 7 between the button 5 and the inner wall of the bottom case 1, and the conduction contact rod 6 connects the incoming line terminal 3 and the outgoing line terminal 4 under the action of the button 5 conduction, a clamp 8 is provided on the inner wall of the bottom case 1, and a heat dissipation air guide pipe 9 is arranged inside the bottom case 1, and the heat dissipation air guide pipe 9 is fixed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com