Non-destructive shaping method of high voltage motor coil

A high-voltage motor without damage technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., to achieve the effects of avoiding manual estimation, improving shaping accuracy, and high automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

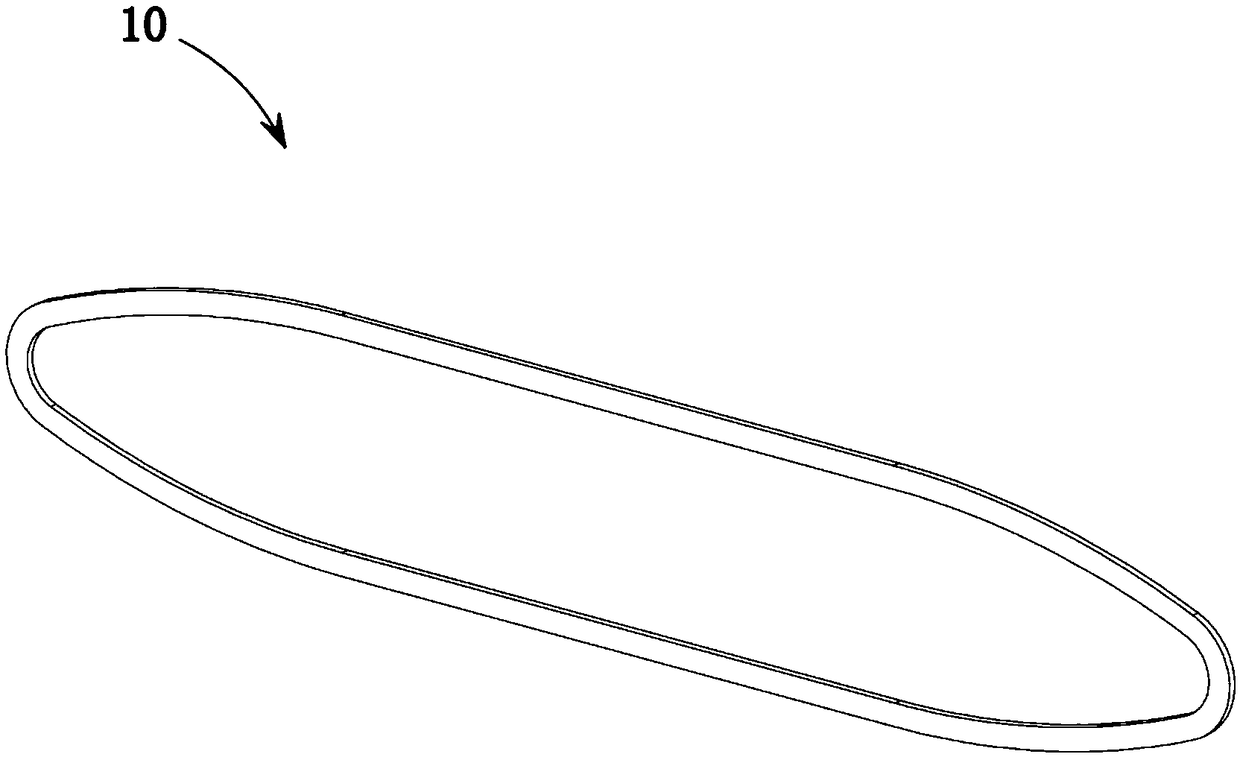

[0065] Such as figure 1 As shown, the coil 10 to be shaped is wound in an elliptical shape by copper wire and the external multi-layer mica tape. In order to adapt to the internal shape of the high-voltage motor, the coil 10 to be shaped needs to be shaped into a curved structure, so as to realize the upper straight section of the coil 10 to be shaped. , The lower straight line segments are arranged in different planes and parallel to each other.

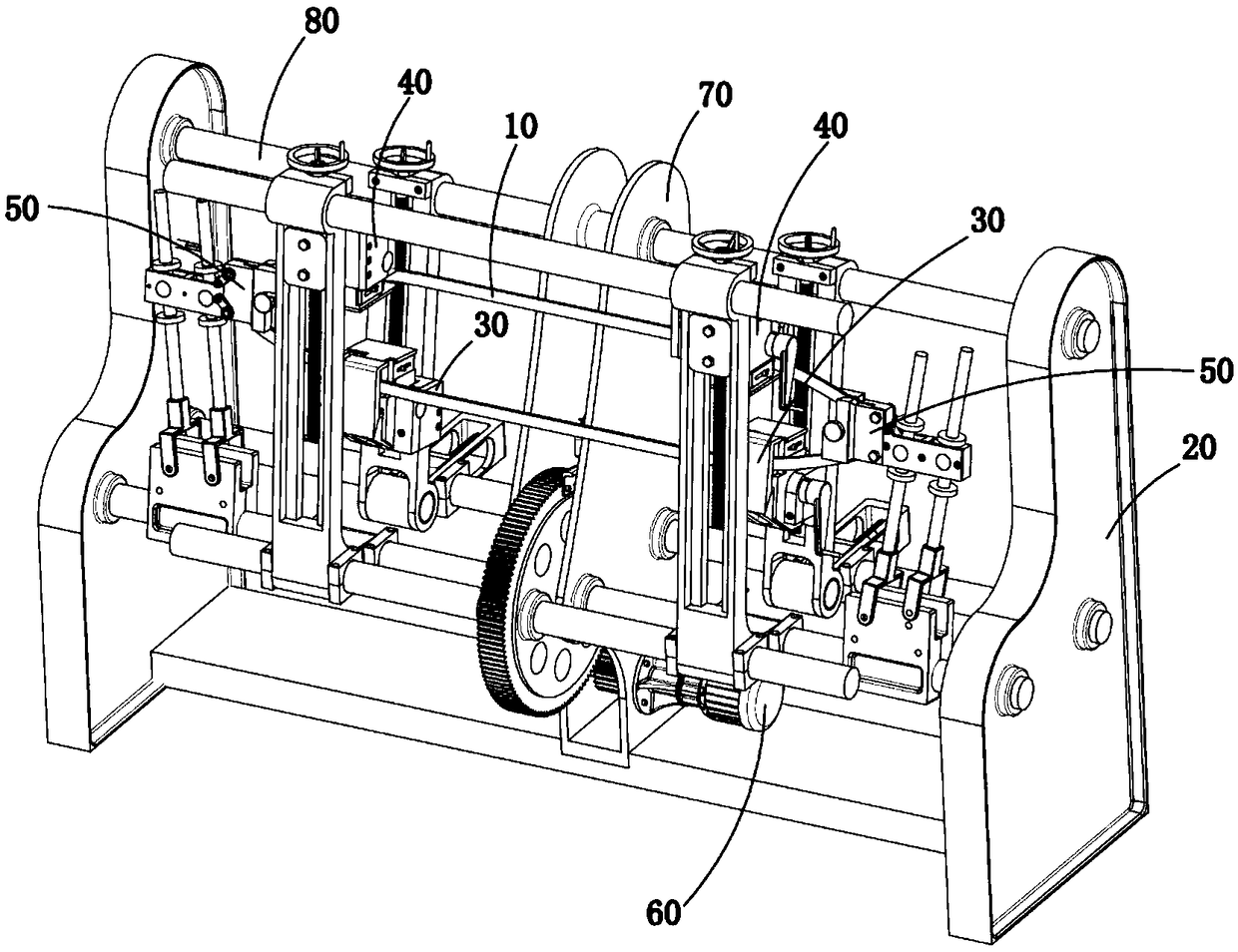

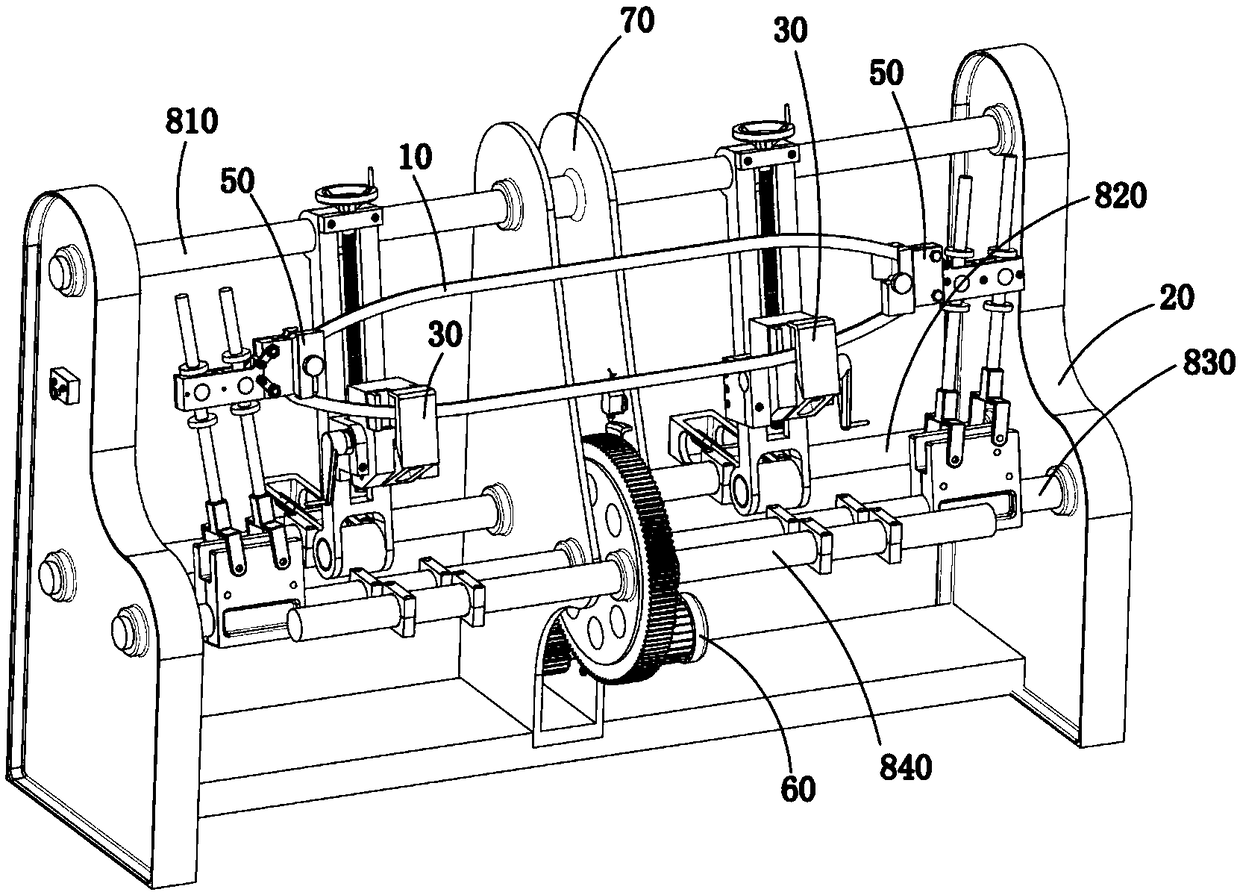

[0066] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com