Laser marking coding method based on visual sensor

A visual sensor and laser marking technology, which is applied in the field of laser marking, can solve the problems of no steps to detect whether the marking information is correct or not, and low detection efficiency, so as to reduce the probability of misjudgment by naked eyes and improve accuracy. rate, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

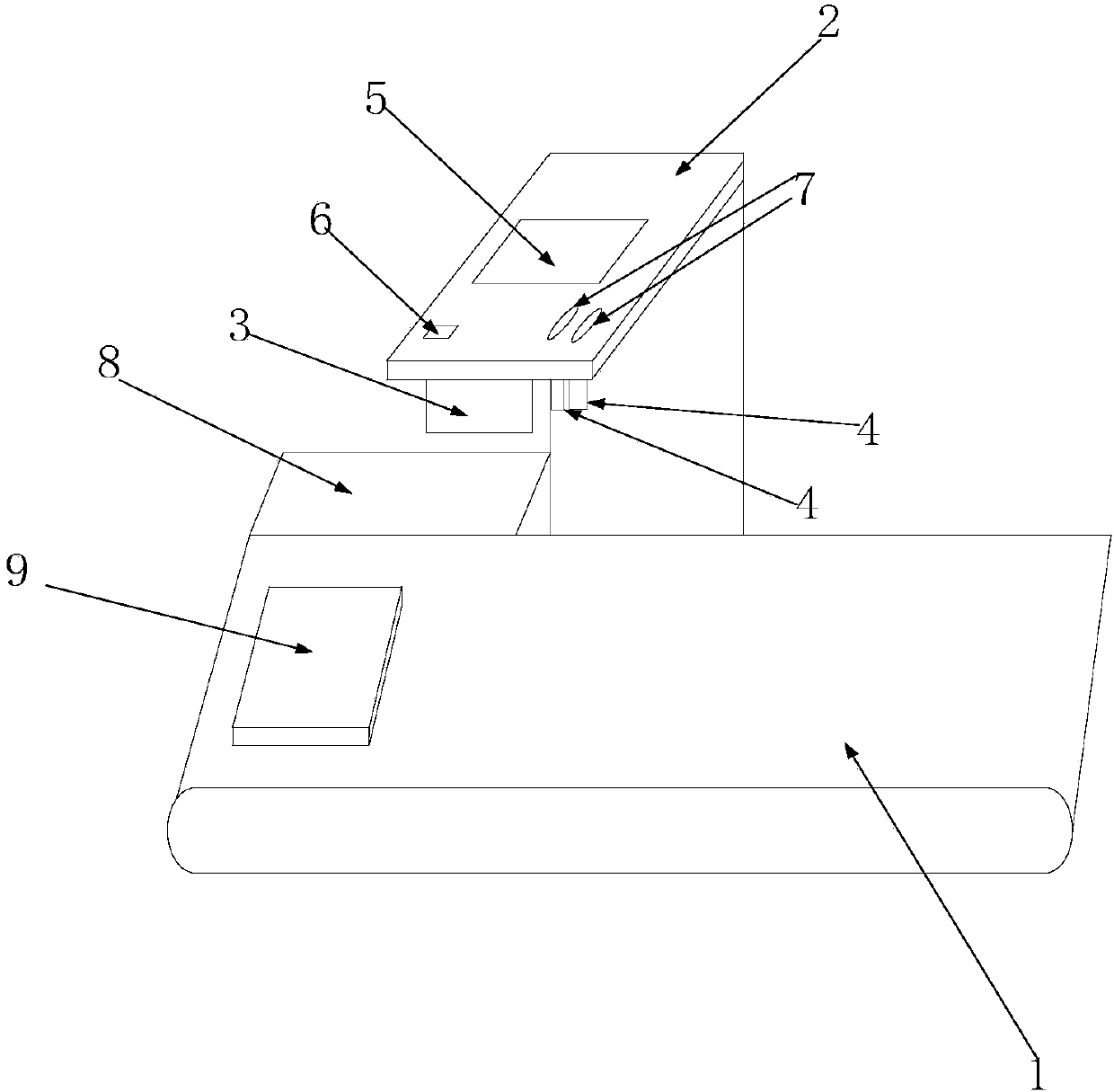

[0027] Such as figure 1 As shown, the laser marking and coding method based on the visual sensor, the following steps are performed in sequence:

[0028] A: Put the product on the conveyor belt and move from left to right under the drive of the conveyor belt;

[0029] B: The laser generator marks the set label or barcode on the surface of the product;

[0030] C: When the products with labels or barcodes continue to be delivered to the vision sensor, the vision sensor collects the visual information of the product and transmits it to the control component;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com