Hauling device for automobile

A technology for traction devices and automobiles, applied in traction connectors, vehicle parts, transportation and packaging, etc., can solve the problems of front vehicle impact force, difficult synchronization speed, front vehicle and rear vehicle damage, etc., and achieve reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

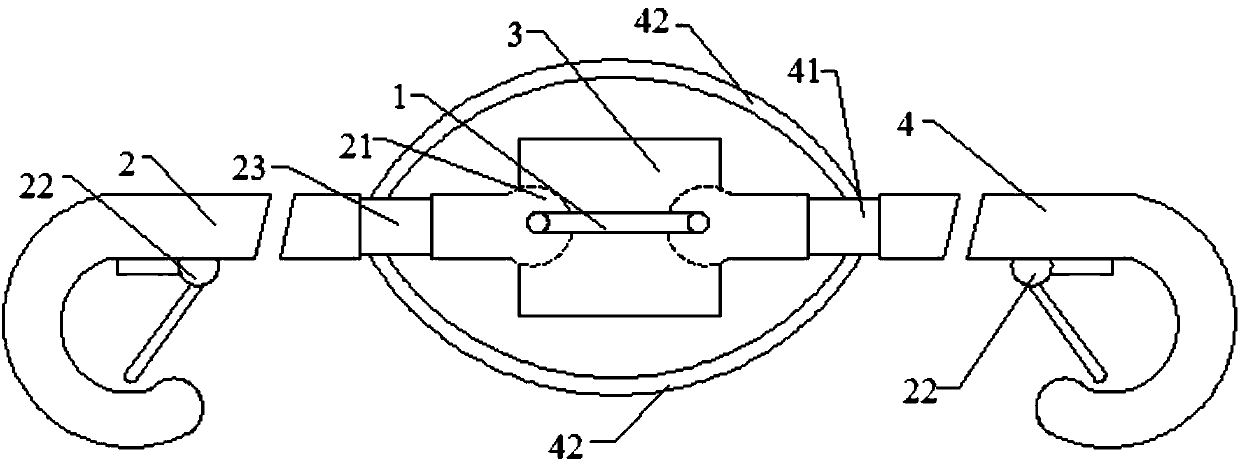

[0013] As shown in the accompanying drawing, a traction device for automobiles comprises: U-shaped fixed ring 1, first traction hook 2, connection block 3, second traction hook 4, and connection block 3 is symmetrically provided with circular arc cross section shaped cavity, the end of the first traction hook 2 and the end of the second traction hook 4 are provided with a convex ball end 21 matching the arc-shaped cavity, and the length of the cavity is the length of the connecting block 3 The end of the cavity is provided with a first groove matching the end of the U-shaped fixed ring 1, and the convex ball end 21 is provided with a perforation matched with the U-shaped fixed ring 1 and the first groove; the connecting block 3 The length of the connection line of the cavity mouth on the top is less than the maximum diameter of the convex ball end 21; after the convex ball end 21 is sleeved on the connection block 3, when actually needed, the U-shaped fixed ring 1 is used to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com