Fuel nozzle and combustor of gas turbine

A technology of fuel nozzles and swirlers, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as fuel nozzle damage, and achieve the effect of reducing emissions and reducing the risk of backfire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

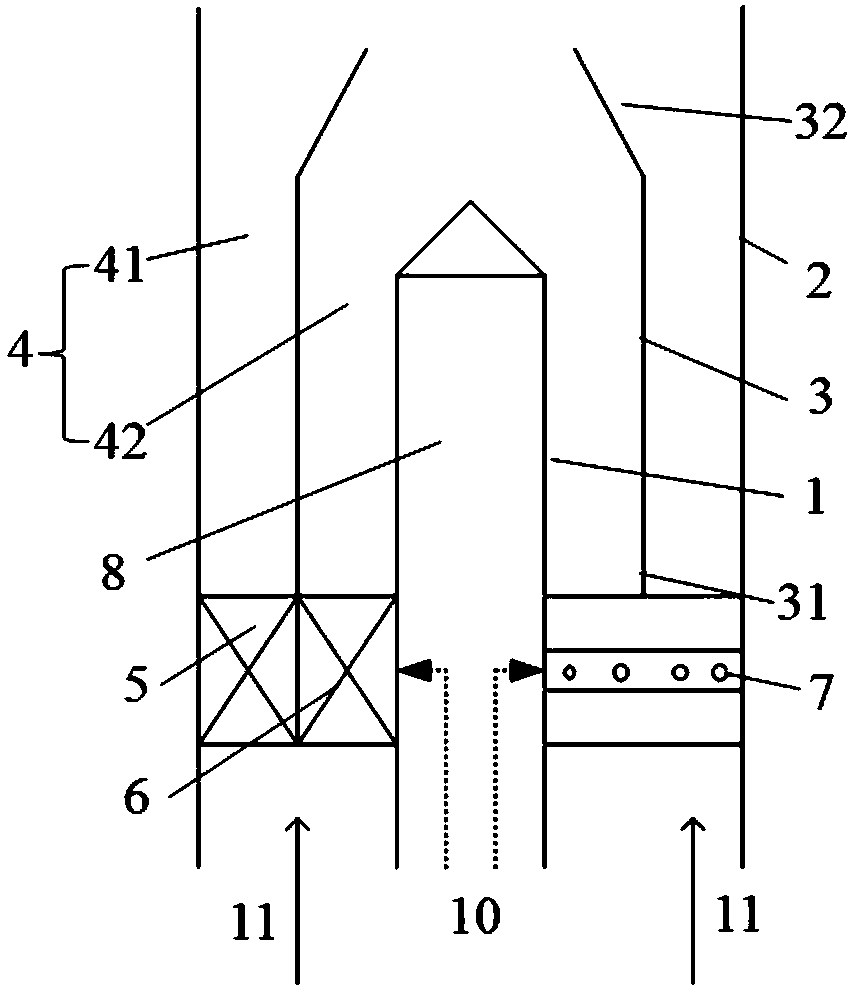

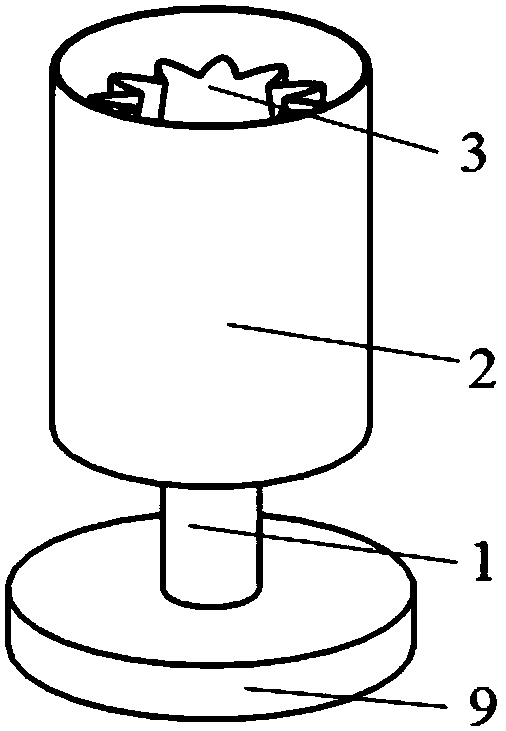

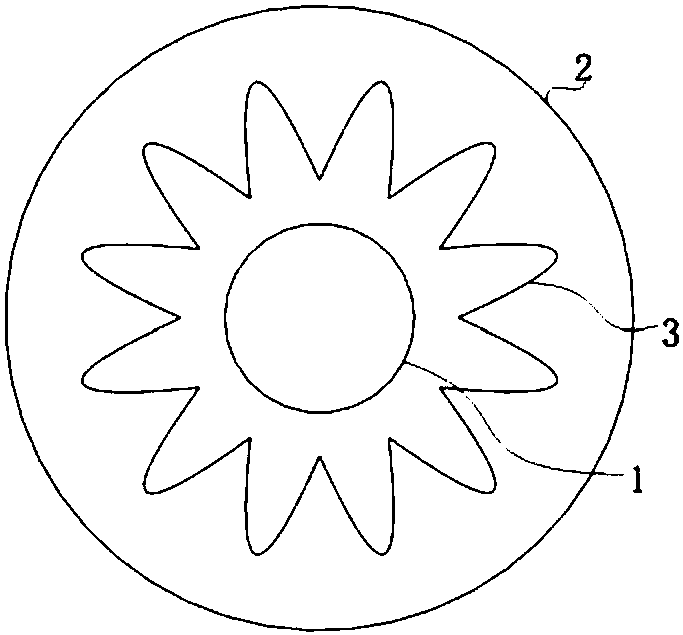

[0024] Such as Figure 1-3 As shown, the fuel nozzle according to the embodiment of the present invention includes a central body 1 , a shroud 2 , an inner cylinder 3 , an outer swirler 5 and an inner swirler 6 .

[0025] The shroud 2 fits on the central body 1 and is radially spaced apart from each other, so that an annular channel 4 is formed between the shroud 2 and the central body 1 .

[0026] The inner cylinder 3 has an inlet end 31 and an outlet end 32, such as figure 1 As shown, both the fuel 10 and the air 11 enter from the bottom up, the lower end of the inner cylinder 3 is the inlet end 31 , and the upper end is the outlet end 32 . The inner cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com