Automotive solid-state relay with PMOS tube and over-current protection

A solid-state relay and overcurrent protection circuit technology, applied in electrical components, electronic switches, pulse technology, etc., can solve the problems of complicated circuit redundancy, high cost, and hindering the popularization and use of solid-state relays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

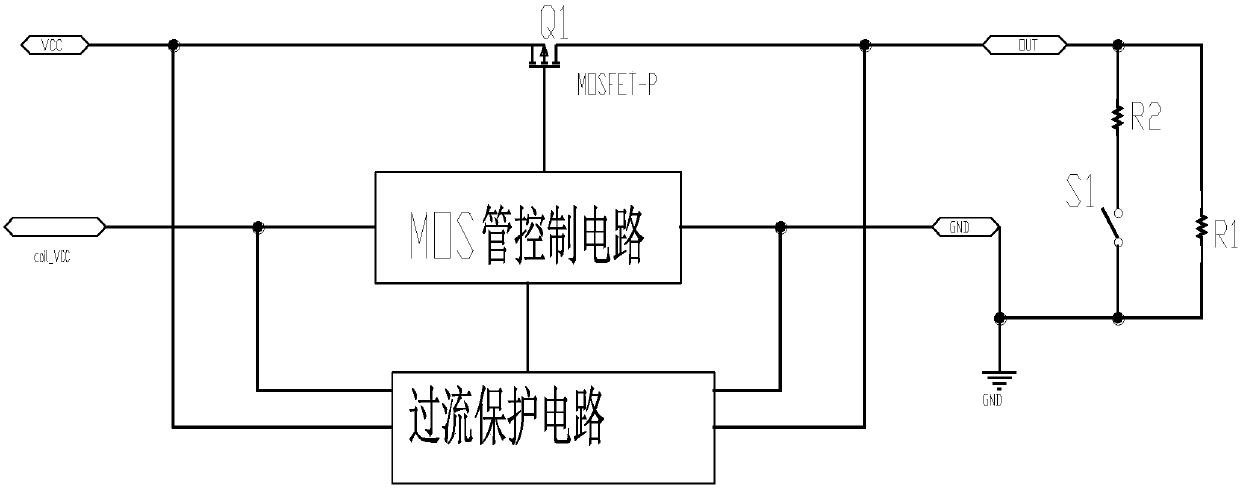

[0016] Such as figure 1 As shown, when coin_VCC (solid state relay control terminal power supply) is powered on, the MOS transistor control circuit drives the MOS transistor Q1 to conduct and output normally.

[0017] When the switch S1 is turned on, the output load increases instantly, and the MOS tube is in the overcurrent stage. The overcurrent protection circuit uses the RDS of the MOS tube itself (the on-resistance of the MOS tube, usually several milliohms to hundreds of milliohms) in the case of overcurrent voltage drop, when the current reaches a certain threshold, the trigger protection circuit turns off the MOS The tube control circuit turns off the MOS tube to realize the overcurrent protection of the MOS tube Q1. This switch S1 is used to simulate an overcurrent situation. When S1 is turned on, the load can be seen and a small resistance is connected, which means that a large load current is added.

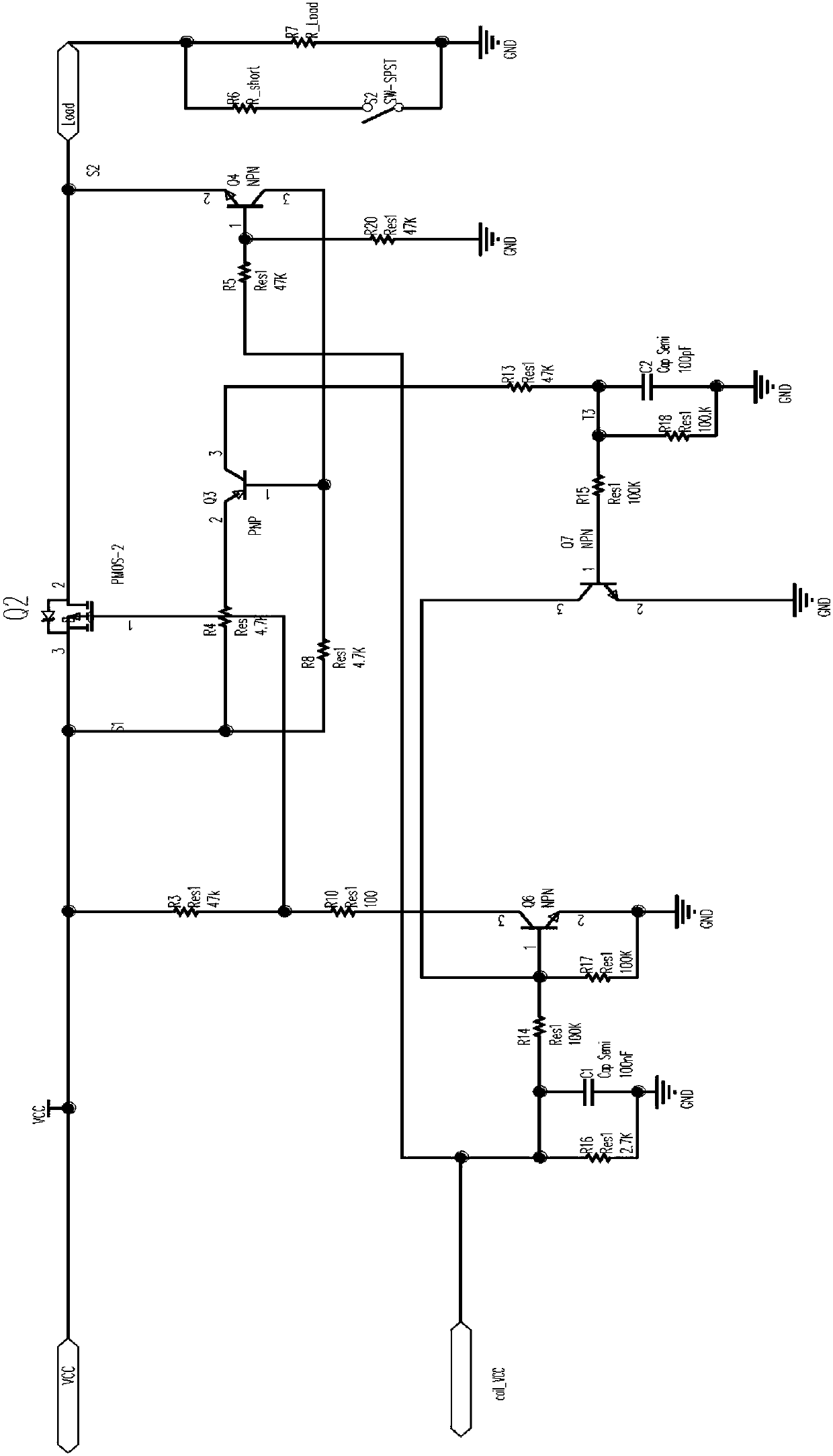

[0018] Such as figure 2 As shown, when the coil_VCC input is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com