Double-outlet-channel saw dust machine dust screening device

A screening device, technology of road sawdust machine, applied in the field of sawdust machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

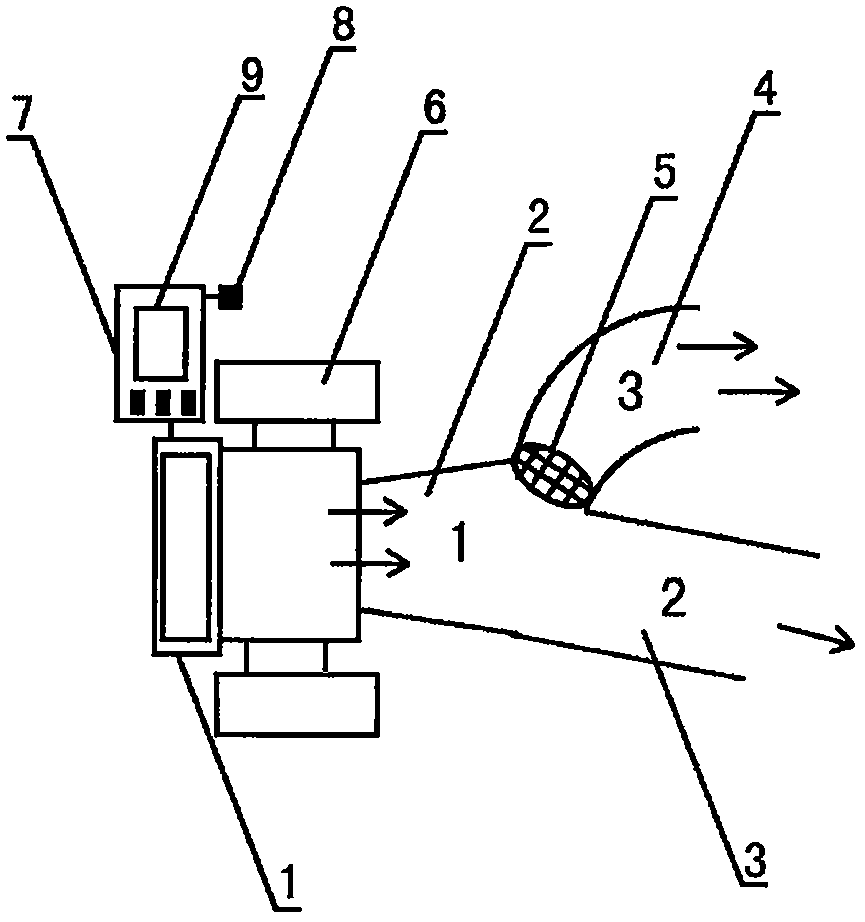

[0012] Embodiment: as shown in the accompanying drawing. The double-outlet sawdust machine powder screening device includes a sawdust machine outlet port (1), and a screening structure is set at the connection of the port (1), including No. 1 comprehensive introduction pipe device (2), No. No. dust powder crossing (4), filter screen (5), the crossings at both ends are controlled by different fan devices (6), and the main control device (7) is located on the sawdust machine. During operation, the wood passes through the sawdust and adjusts the corresponding wind speed to circulate. The sawdust particles and dust are sorted and recycled separately.

[0013] The double outlet sawdust machine powder screening device is equipped with a prompting device (8), and the mode of prompting information is sound or LED light display.

[0014] The powder screening device of the sawdust machine with double outlets, each pipeline is equipped with a flow velocity sensing module, and the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com