Disc type bagged material detection device for powder packing machine

A detection device and a technology for bagged objects, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as insufficient protection, complicated cleaning, powder scattering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

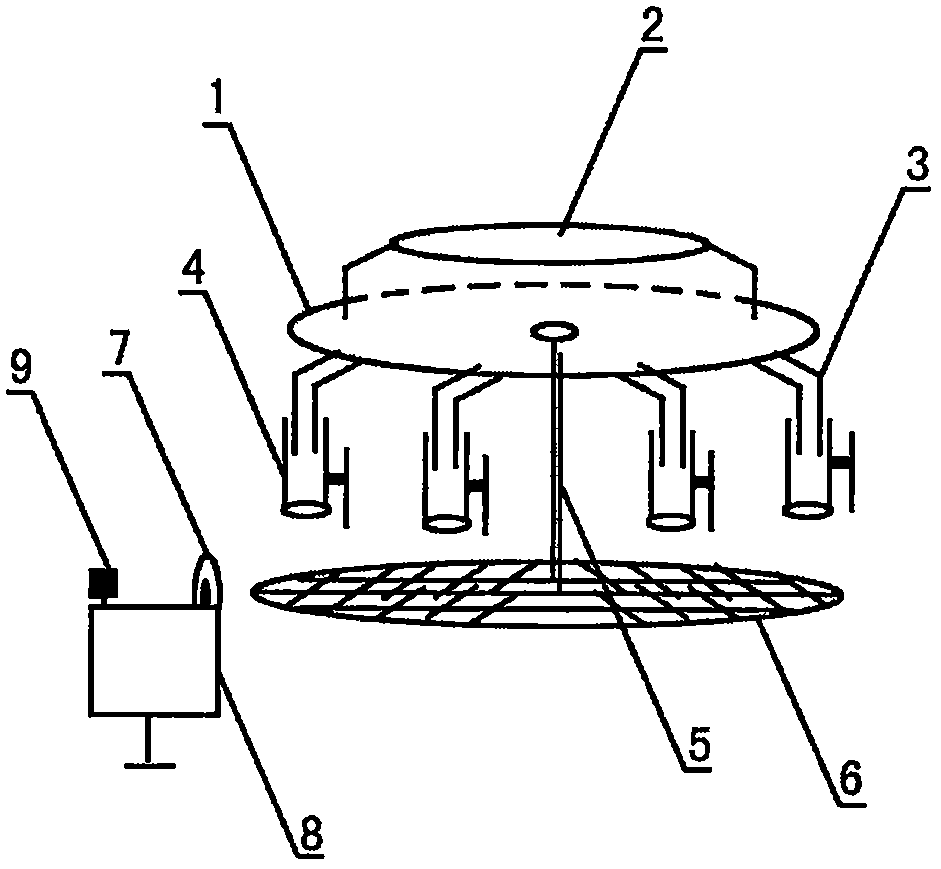

[0012] Embodiment: as shown in the accompanying drawing. Disc-type bag detection device for powder packaging machine, including a frame (1), the frame (1) is designed in a disc structure, and the upper end is equipped with an air pressure storage device (2), a telescopic air induction pipe (3), and an inflatable cover (4), a vertical support rod device (5) is arranged in the middle, and the rod body is located in the middle of the ventilation induction network (6). When the bag is in an open state during operation, an equal amount of gas is charged, and the information transmission module (7) transfers the air flow The sensing data is transmitted to the computer component (8) for analysis and screening and corresponding prompts are made.

[0013] The disc-type bag detection device of the powder packaging machine is equipped with a prompting device (9), and the prompting information is displayed by sound or LED light.

[0014] In the disc type bag detection device of the powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com