Fine adjusting structure for pushing workpiece of opening grinding machine

A workpiece and grinding technology, which is applied in the field of grinding machine, can solve the problems of low stability and long working time of a single workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

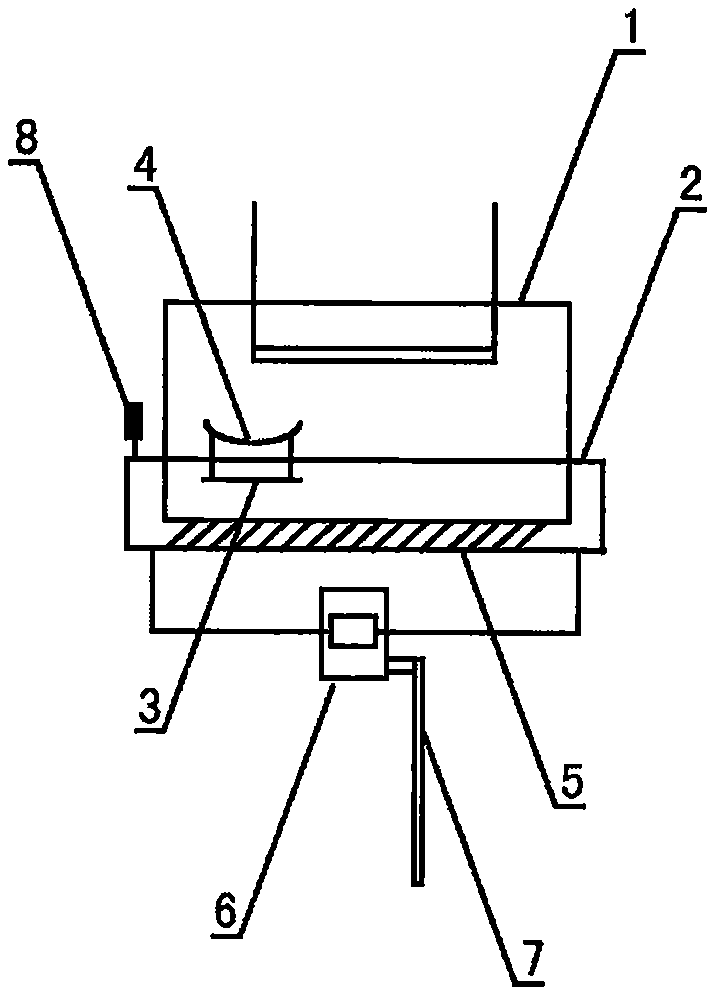

[0012] Embodiment: as shown in the accompanying drawing. The fine-tuning structure used for pushing the workpiece of the grinding machine includes a grinding machine operating table (1), and the fine-tuning structure is arranged on the outer side of the operating table (1), including a concave table (2), a positioning base (3), a rotating surface (4), the horizontal pushing device (5), the lifting device (6) is suspended on the outside of the table and connected with the operating handle (7), the workpiece is placed at a fixed position during operation, and its horizontal direction is adjusted synchronously according to the grinding frequency of the grinding machine And the rotation speed, after the incision is ground, the workpiece is tilted and placed on the grinding belt for repair work.

[0013] The fine-tuning structure used for pushing the workpiece of the grinding machine is provided with a prompting device (8), and different prompting messages are sent out when the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com