A medical equipment cleaning and disinfection device and disinfection method

A technology for cleaning and sterilizing medical equipment, applied in cleaning methods and utensils, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of broken glass jars, secondary pollution, time-consuming and labor-intensive, etc. time, the effect of avoiding recontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

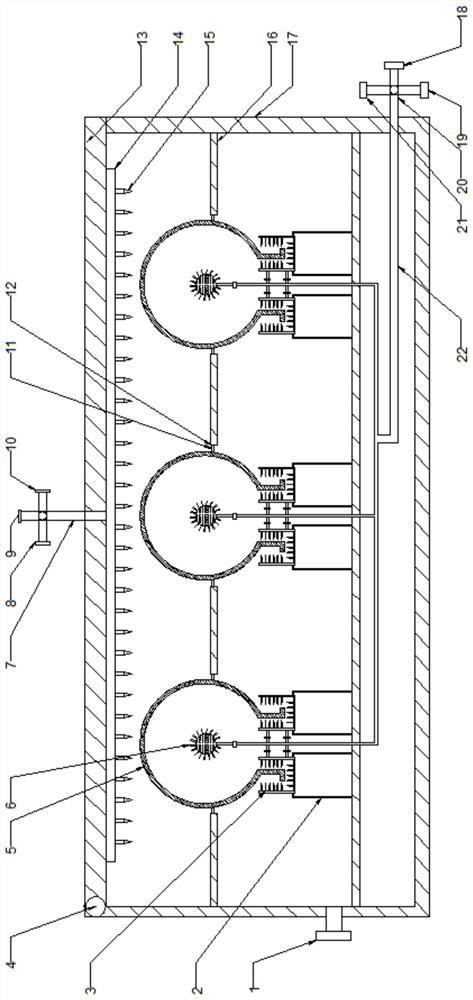

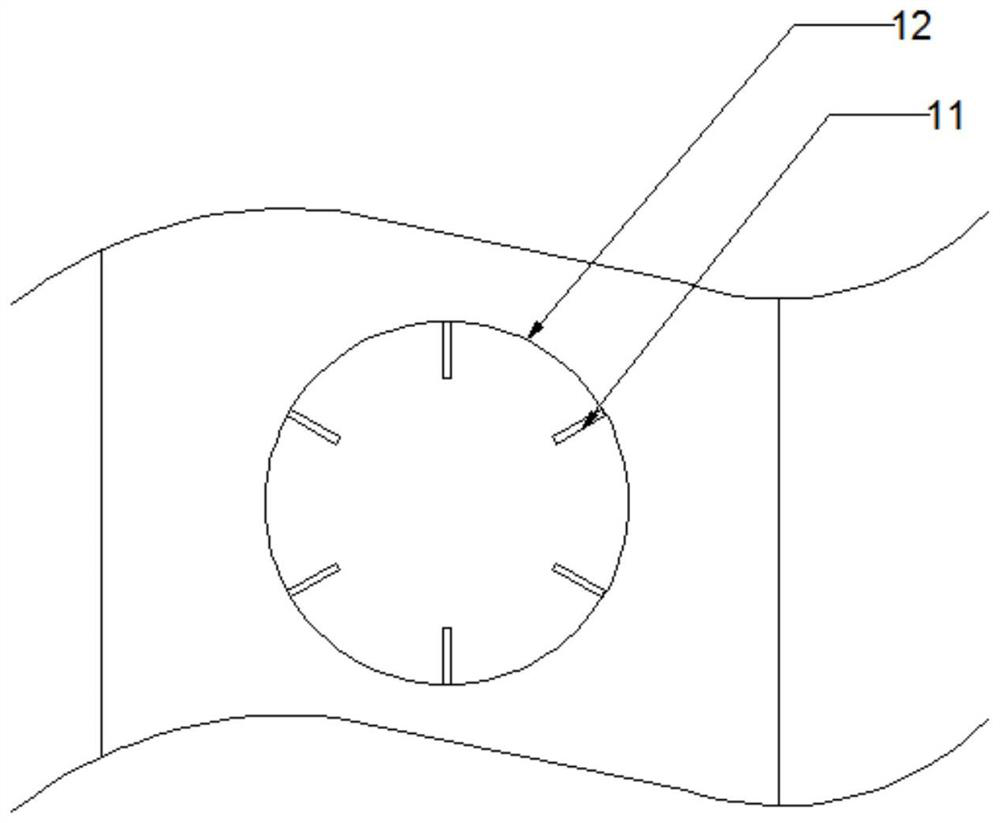

[0037] A cleaning and disinfection device for medical equipment of the present invention, comprising a sewage quick interface 1, a bracket 2, a secondary cleaning mechanism 3, a hinge 4, a glass jar 5, a primary cleaning head 6, a bracket 11, a fixing hole 12, and an upper cover 13. Liquid distribution air distribution plate 14, primary nozzle 15, partition 16, cleaning box 17;

[0038] One end of the upper cover 13 is hinged at the opening of the cleaning box 17 through a hinge 4, and the bottom end of the upper cover 13 facing the side of the cleaning box 17 is provided with a liquid distribution air distribution plate 14, and the liquid distribution air distribution plate The bottom end of 14 is provided with primary nozzles 15 distributed in a matrix, and the liquid and air distribution plate 14 is selectively connected to the cleaning agent supply source, the disinfectant supply source and the hot air supply source;

[0039] The bottom end of the cleaning box 17 is provid...

Embodiment 2

[0046] This embodiment is improved on the basis of Embodiment 1. The top of the liquid distribution and air distribution plate 14 is connected to the upper supply pipeline 7, and the end of the upper supply pipeline 7 is provided with a first four-way valve. A four-way valve is respectively connected to the first cleaning agent connection port 8 , the first disinfectant connection port 9 and the first hot air connection port 10 through pipelines.

[0047] As a preferred manner, the first cleaning agent connection port 8, the first disinfectant connection port 9, and the first hot air connection port 10 are all arranged on the outside of the upper cover 13, so as to facilitate the connection of corresponding supply pipes.

[0048]As a preferred manner, the first cleaning agent connection port 8 , the first disinfectant connection port 9 , and the first hot air connection port 10 all adopt quick connections.

[0049] The setting of the quick interface is convenient for quick ins...

Embodiment 3

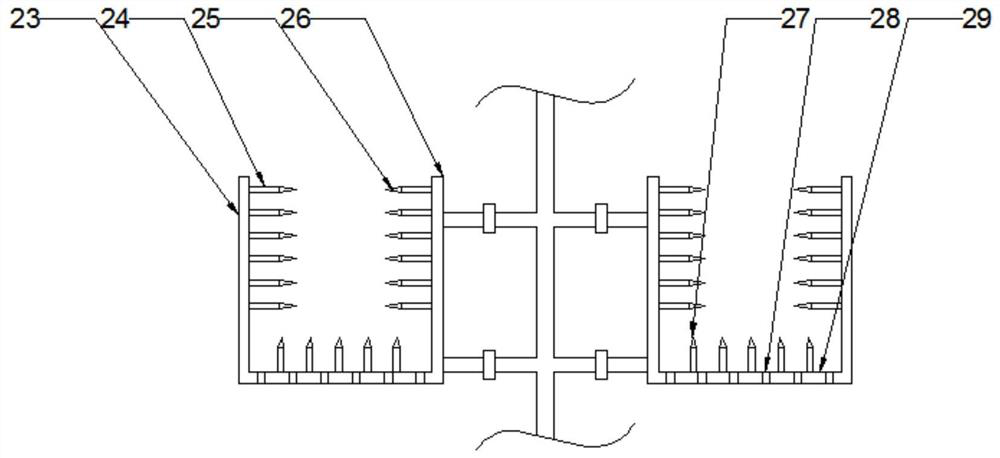

[0051] This embodiment is improved on the basis of Embodiment 1. The secondary cleaning mechanism 3 includes an outer annular liquid distribution air distribution plate 23 , an inner annular liquid distribution air distribution plate 26 and a lower liquid distribution air distribution plate 29 . The inner side of the annular liquid distribution wind plate 23 is evenly distributed with outer nozzles 24, the outer nozzles 24 point to the outer wall of the opening position of the glass jar 5, the inner nozzles 25 point to the inner wall of the opening position of the glass jar 5, and the lower nozzles 27 point to the inner wall of the opening position of the glass jar 5. At the opening position of the glass jar 5, there are a plurality of liquid-permeable holes 28 on the lower liquid-distributing air-distributing plate 29. The arrangement of the liquid-permeable holes 28 facilitates the downward flow of disinfectant and cleaning agent.

[0052] As a preferred manner, the secondary...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap