Moisture Protection Methods for Black and White Printers

A printer, black and white technology, applied in the direction of printing device, printing, thin material processing, etc., can solve the problems of black and white printers that cannot prevent moisture and dust, and achieve the effect of solving the problem of not being able to prevent moisture and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below by means of specific embodiments:

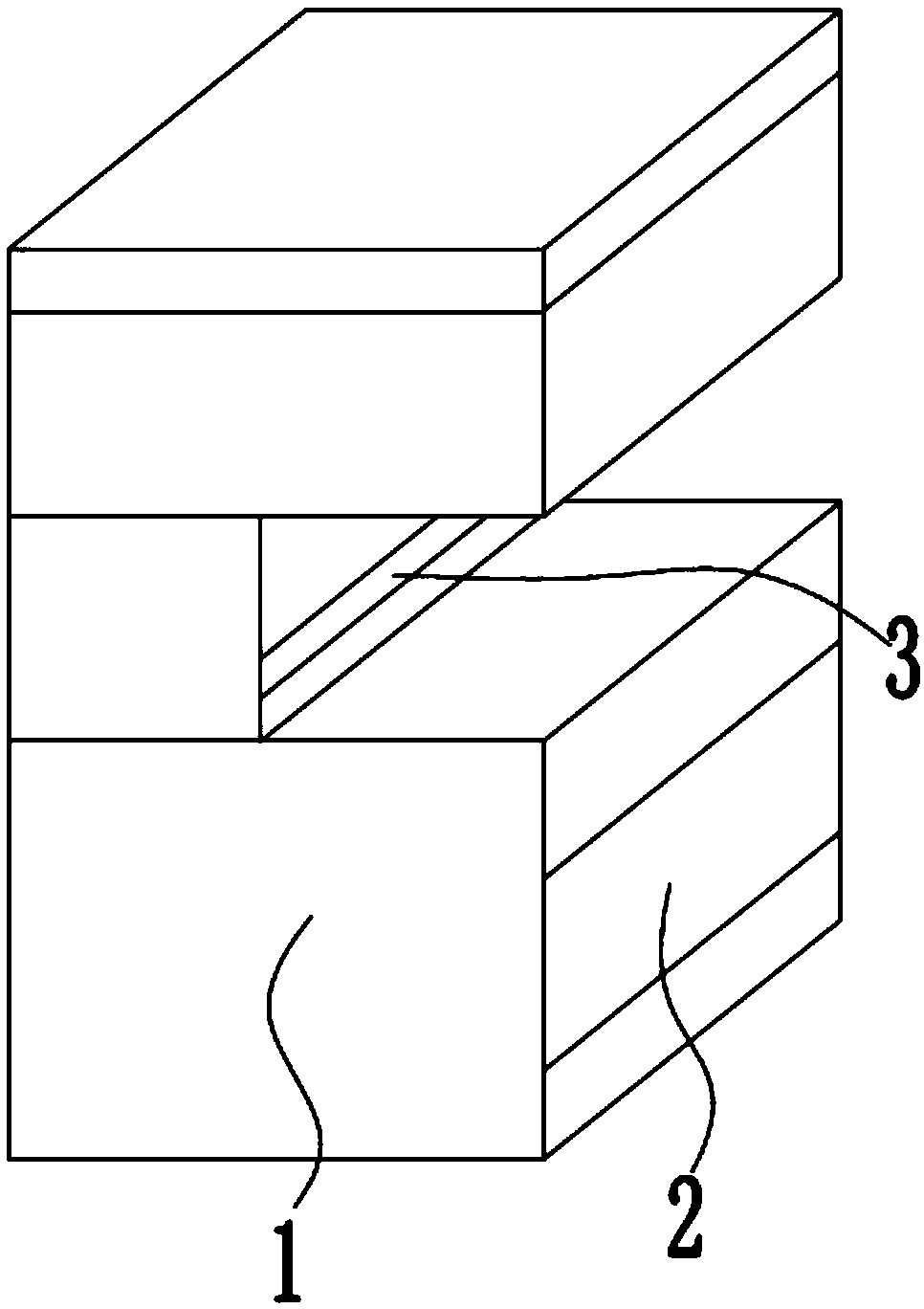

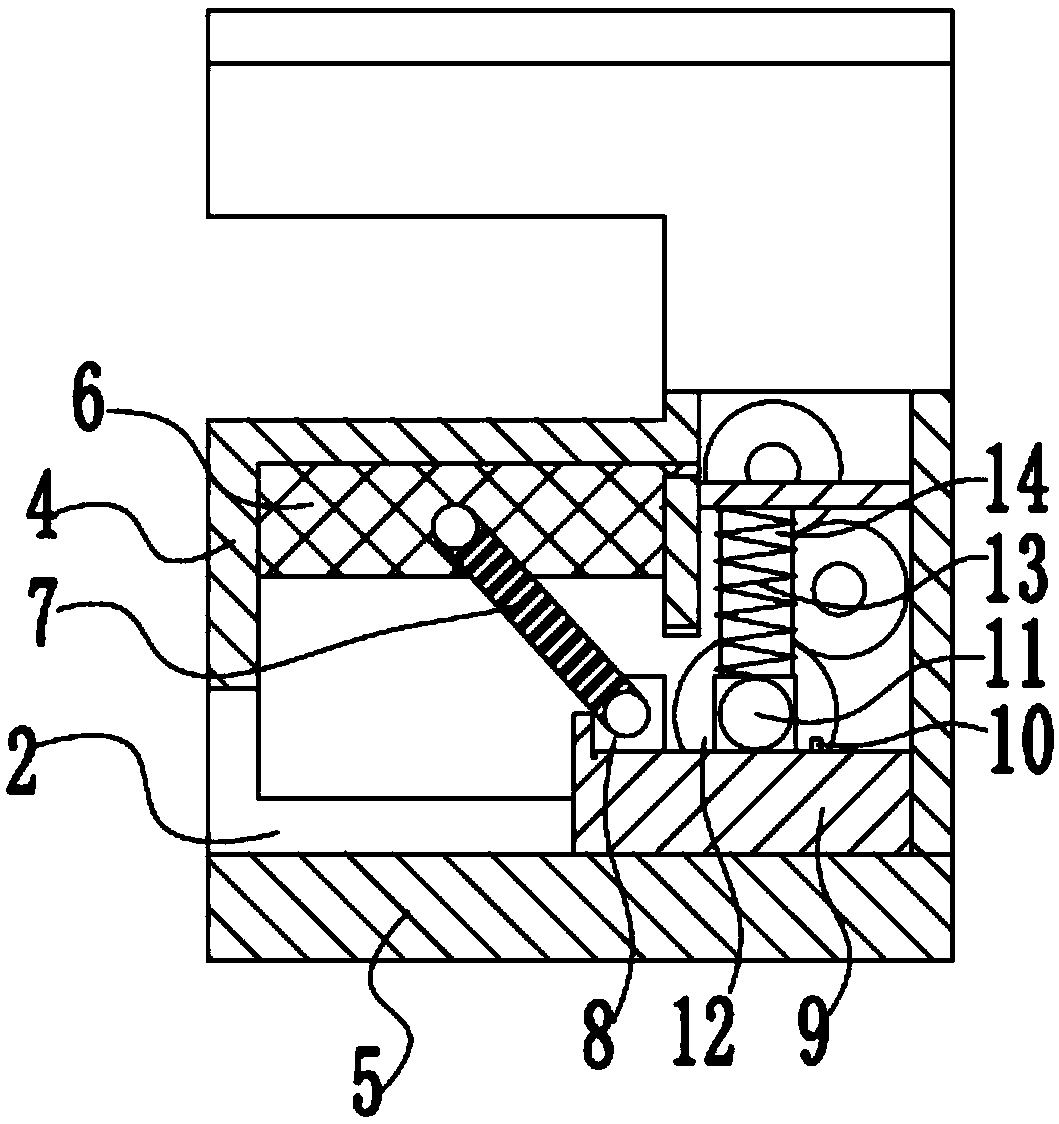

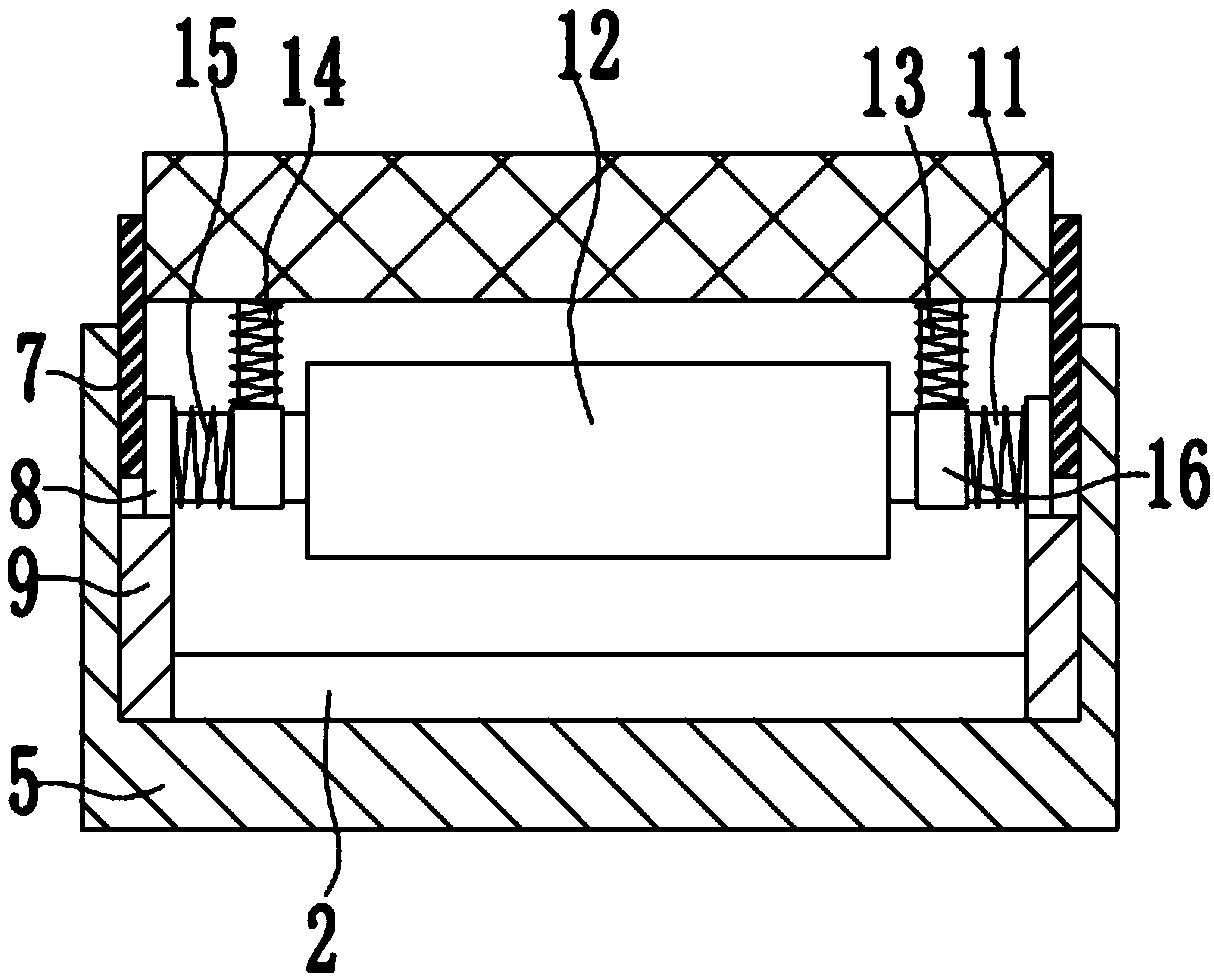

[0030] The reference signs in the drawings of the specification include: chassis 1, carton 2, paper outlet 3, upper cover 4, lower cover 5, shielding frame 6, connecting rod 7, sliding seat 8, sliding table 9, limit block 10 , rotating shaft 11, paper roller 12, compression spring 13, guide post 14, torsion spring 15, screw mandrel seat 16.

[0031] as attached figure 1 As shown, the existing large printers generally include a carton 2 for placing paper, and the carton 2 is slidingly connected to the cabinet 1 in a drawer type. The case 1 includes an upper cover 4 and a lower cover 5 in a rectangular structure. The paper outlet 3 is located above the upper cover 4 . A paper roller 12 for feeding the paper in the paper tray 2 into the printing assembly is installed in the cabinet 1 . The upper cover 4 and the lower cover 5 respectively include first and second left pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com