Cylindrical battery material taking mechanism

A technology of reclaiming mechanism and cylindrical battery, which is applied in the direction of secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., and can solve problems such as unsafe methods, easily damaged batteries, and low battery absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described.

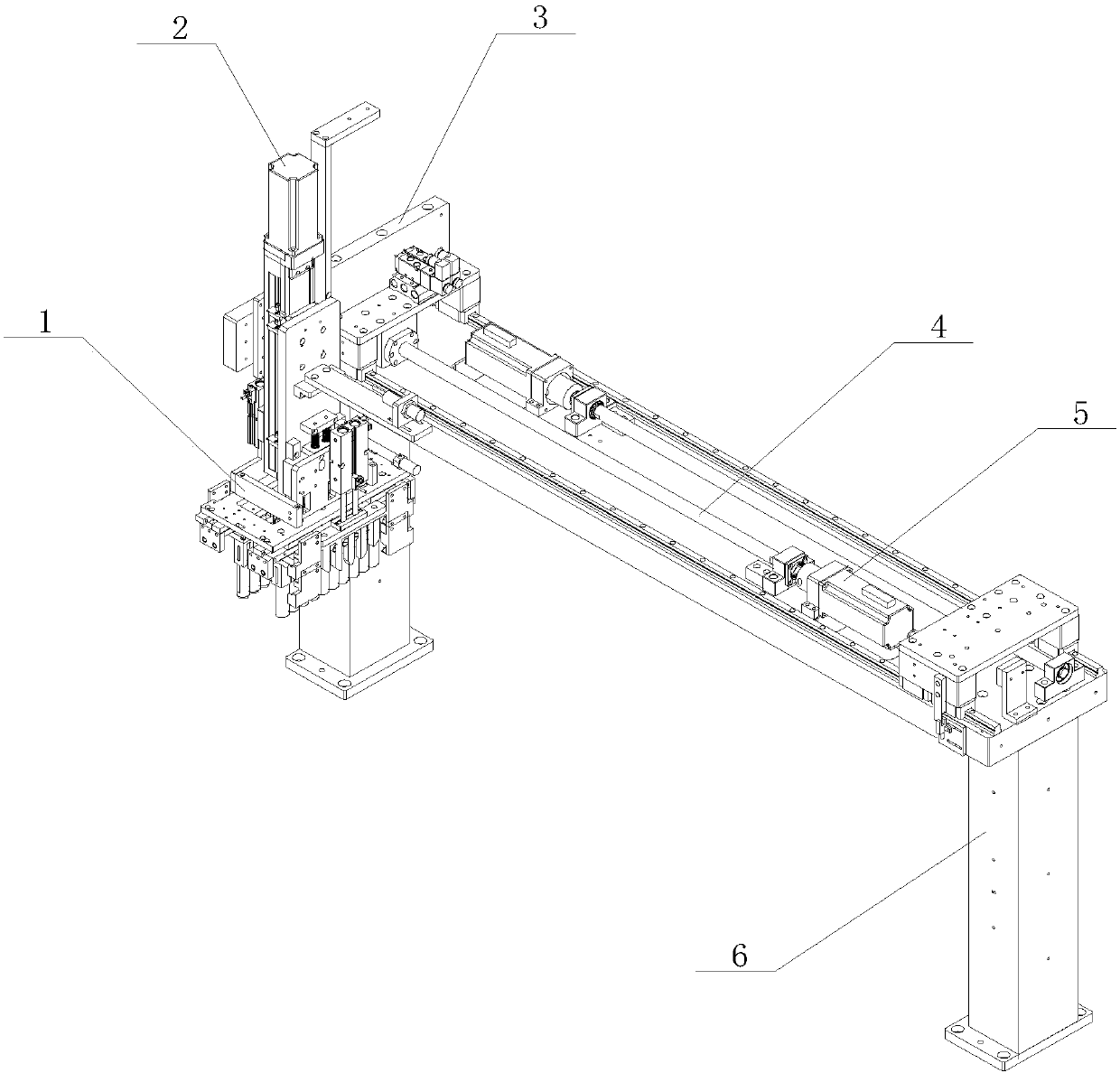

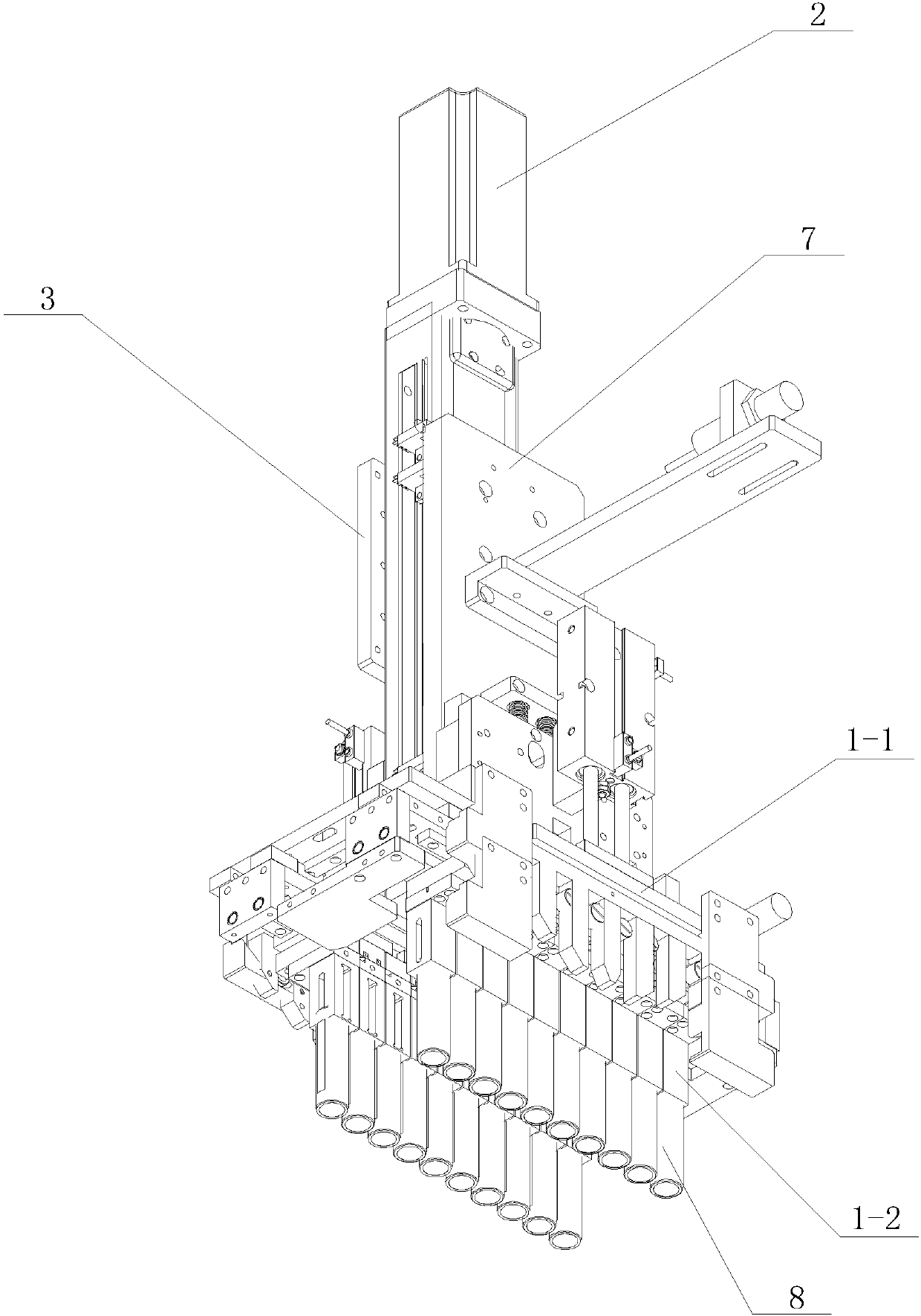

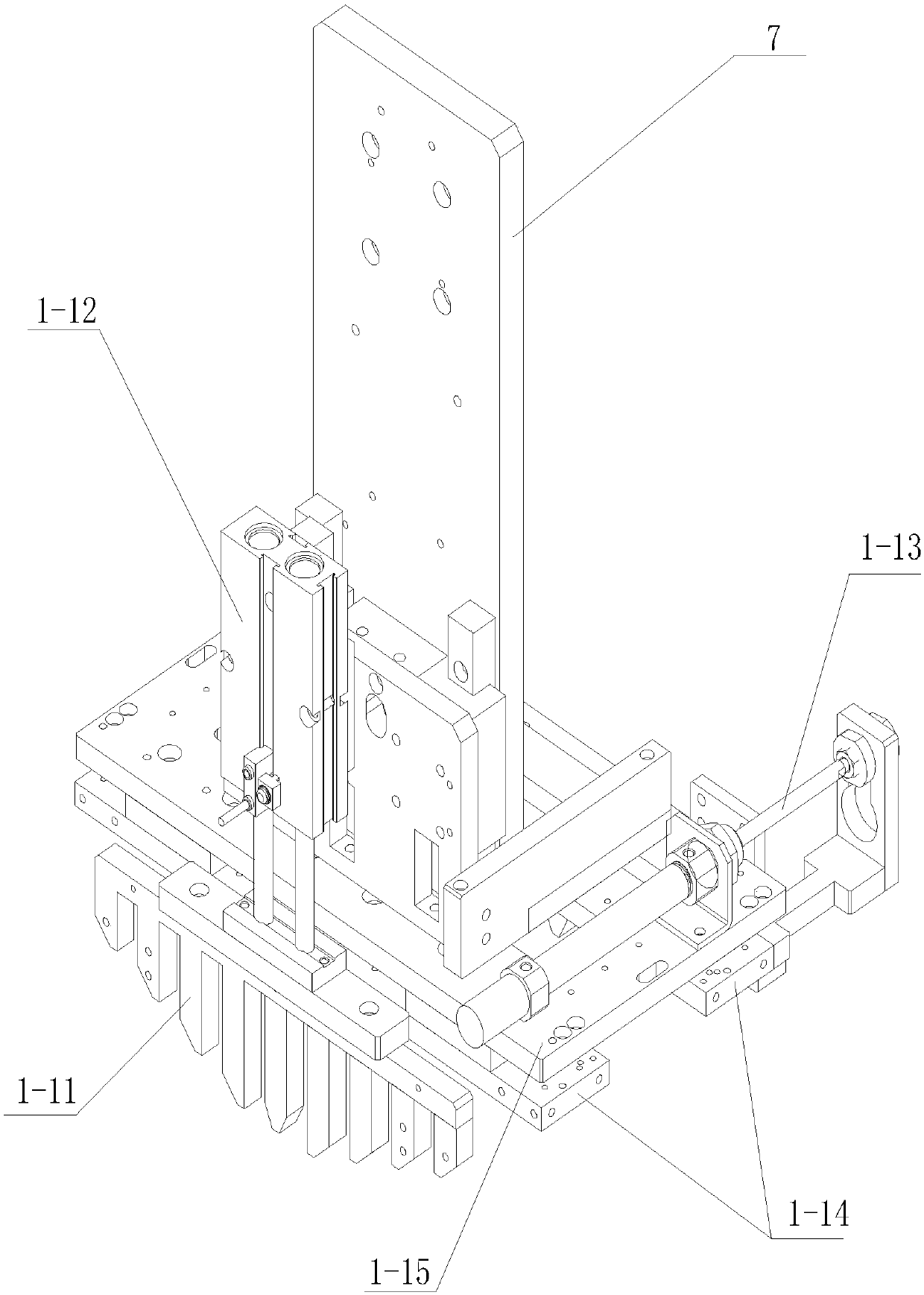

[0029] see Figure 1-2 As shown, the technical solution adopted in this specific embodiment is: it comprises frame 6, drive motor 1, jaw device 1; The workbench of described frame 6 is provided with Y-axis motion leading screw 4; The moving screw 4 is connected to the driving motor 1 through transmission; the Y-axis moving screw 4 is slidably connected with a jaw fixing plate 3; the jaw fixing plate 3 is fixed with a driving motor 2 along the X axis; the driving motor 2 2 is connected to the X Axis movement lead screw transmission connection; X-axis movement lead screw is set on X-axis slide rail; X-axis movement lead screw is slidingly connected with module connection plate 7; jaw device 1 is fixed on module connection plate 7; The device 1 includes a chuck adjusting device 1-1 and a chuck device 1-2;

[0030] see figure 2 As shown, the number of the collet adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com