Push-pull type electromagnet projectile launcher

A projectile launcher and push-pull technology, which is applied to electromagnetic launchers, weapon types, weapons without explosives, etc., can solve the problems of poor user experience and competitiveness, unsatisfactory user experience, and inconvenient operation, etc. Variety of playing methods, stable power and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

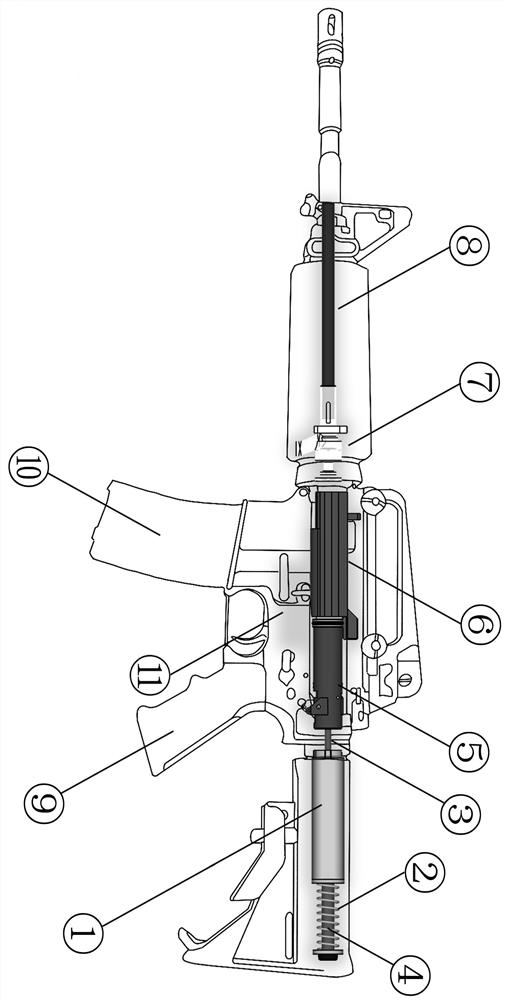

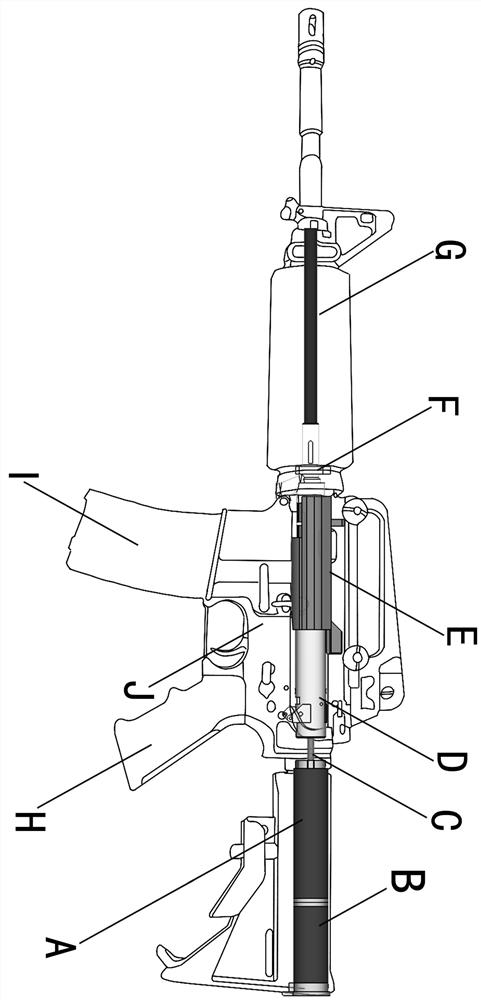

[0011] Please refer to: Figure (1) Spring Return Type Push-Pull Electromagnet Projectile Launcher, Figure (2) Push-Pull Electromagnet Reset Type Push-Pull Electromagnet Projectile Launcher.

[0012] The push-pull electromagnet projectile launcher uses 7.4V-48V power supply; after the push-pull electromagnet is energized, the moving iron core makes a linear motion, and the principle of stopping when the power is off, the moving iron core drives the piston to compress the gas in the cylinder, and the return spring Or reset the moving iron core with a push-pull electromagnet to complete a working cycle.

[0013] Figure (1) shows the spring return push-pull electromagnet projectile launcher, which is mainly composed of ① push-pull electromagnet coil, ② return spring, ③ push-pull connecting rod, ④ moving iron core, ⑤ piston, ⑥ cylinder, ⑦ push nozzle , ⑧Launcher inner tube, ⑨Grip battery compartment, ⑩Launcher magazine, ⑪Launcher main body;

[0014] Figure (2) shows the push-pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com