Feeding mechanism for cross-feeding directly from the vibrating plate to the linear track

A technology of linear track and feeding mechanism, which is applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of slow feeding speed, instability, and complex structure, and achieve simple structure, unique design, and breakthrough The effect of limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

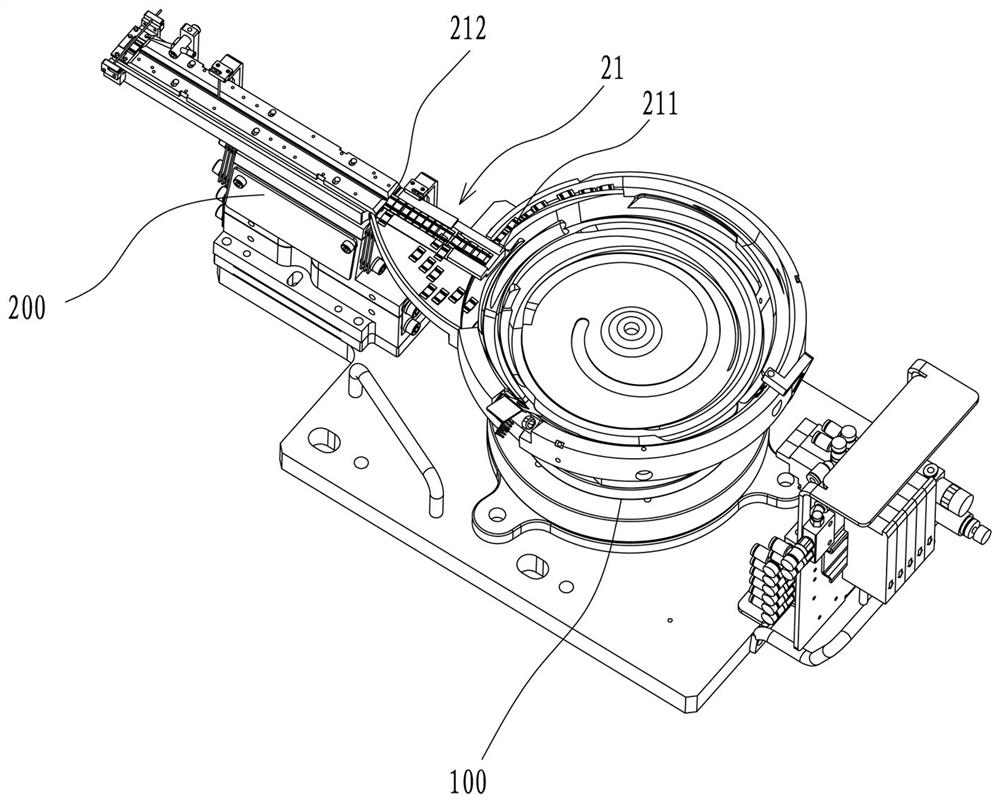

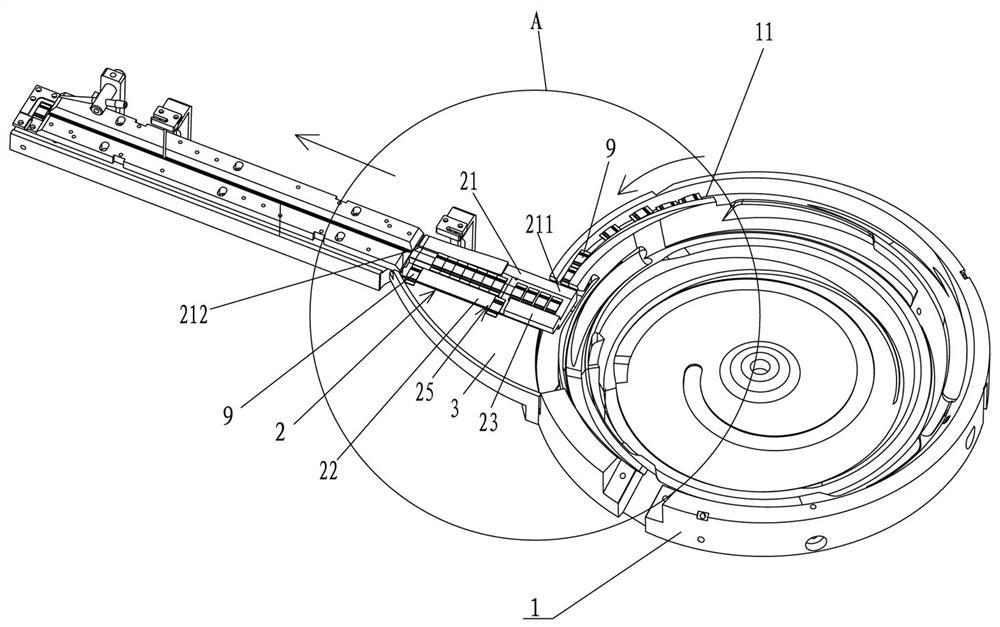

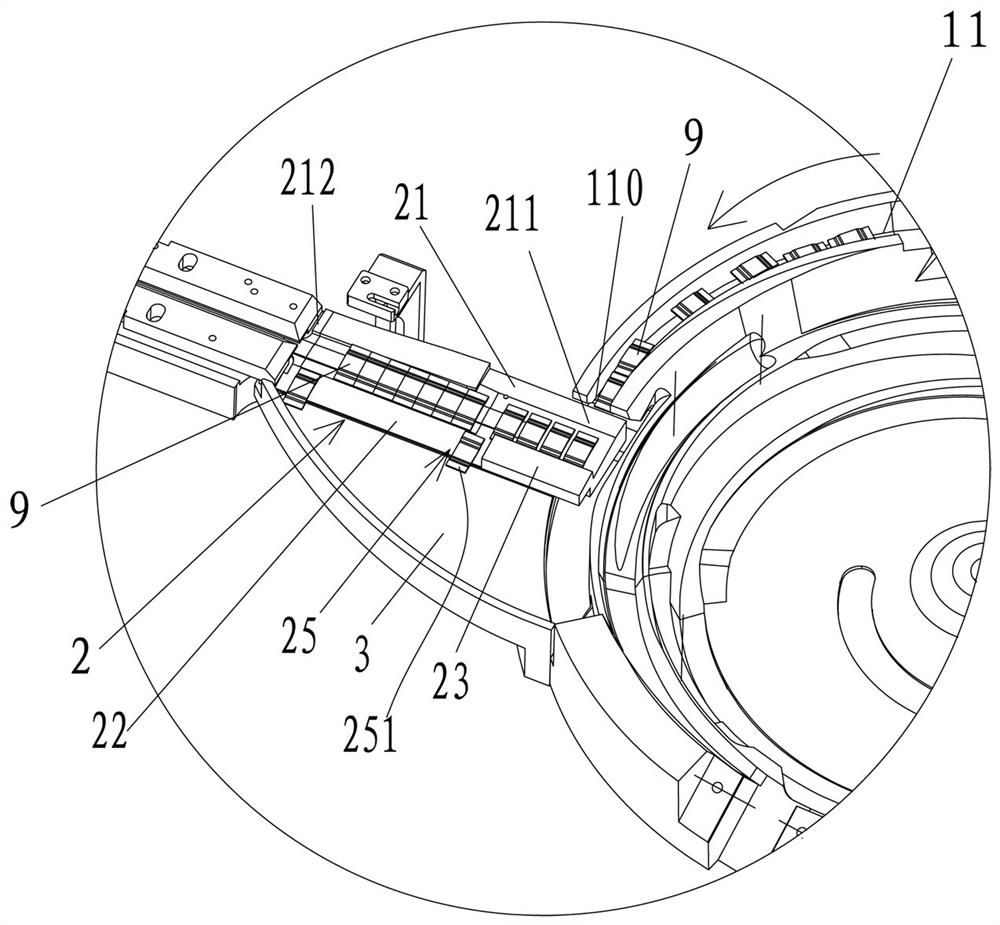

[0016] See Figure 1 to Figure 4 , Figure 1 to Figure 4 What is shown is an embodiment of a feeding mechanism that can directly realize horizontal feeding from a vibrating plate to a linear track. A feeding mechanism that can directly realize horizontal feeding from a vibrating plate to a linear track includes a feeding mechanism with The circular vibration feeding device 100 of the disk 1 and the direct vibration conveying device 200 with the direct vibration rail 2, the feeding disk 1 has the feeding rail 11 for longitudinal feeding, and the direction of the workpiece 9 on the direct vibration rail 2 The direction of the workpiece 9 at the outlet end 110 of the feeding track 11 is perpendicular to each other, and the direction of the workpiece (9) on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com