Grinding mill for gardens

A grinder and gardening technology, which is applied in grain processing and other fields, can solve the problems such as difficult to achieve small crushing of fallen leaves and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

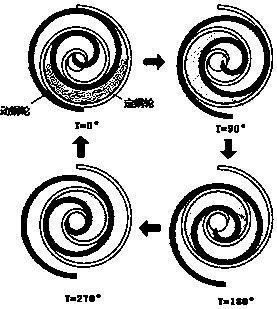

[0028] Such as figure 1 Shown is a schematic diagram of the grinding movement principle of the embodiment of the present invention, the moving worm gear and the fixed worm gear both adopt involute curve parameters, and the phase difference is π. Assembling the moving worm wheel and the fixed worm wheel will form a crescent-shaped sealed pressure chamber. During the grinding process, the fixed worm wheel is fixed and the moving worm wheel rotates. The pressure chamber is gradually squeezed from the outside to the inside. Due to the linear velocity of each point of the moving worm wheel Different, in addition to being squeezed, the blade is also stretched by friction, causing the blade to break.

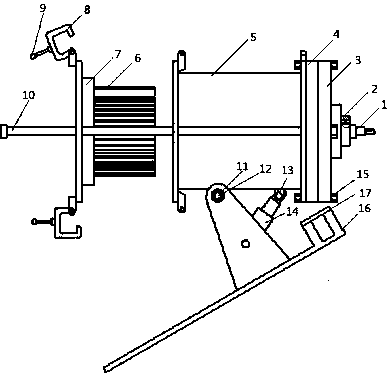

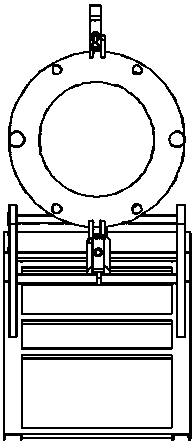

[0029] Such as Figure 2~13As shown, the main shaft 1 and the sleeve 5 transmit torque through the deep groove ball bearing 2, the inner hole of the eccentric adjustment block 22 is set on the eccentric flat shaft of the main shaft 1, the outer circle is set on the moving worm wheel b...

Embodiment 2

[0032] see Figure 6 and Figure 8 , according to the grinding processing requirements, by changing the radius of the base circle of the movable worm wheel and the fixed worm wheel, the pressure chamber is enlarged or reduced, thereby controlling the size of the single-piece area of the fallen leaves after grinding. For the rest of the undescribed parts, see Example 1, no longer repeat.

Embodiment 3

[0034] see Figure 10 , while keeping the vortex profile parameters of the movable worm wheel and the fixed worm wheel unchanged, by changing the eccentricity of the eccentric adjustment block, the size of the pressure chamber can also be fine-tuned to meet the requirements of different grinding areas of single fallen leaves. The above part is shown in Embodiment 1 and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com