Efficient wood door paint spraying device

A technology for spraying equipment and wooden doors, applied in spray booths, spraying devices, etc., can solve problems such as air pollution, paint flying around, excessive paint spraying, etc., and achieve the effects of improving efficiency, reducing the entry into the atmosphere, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

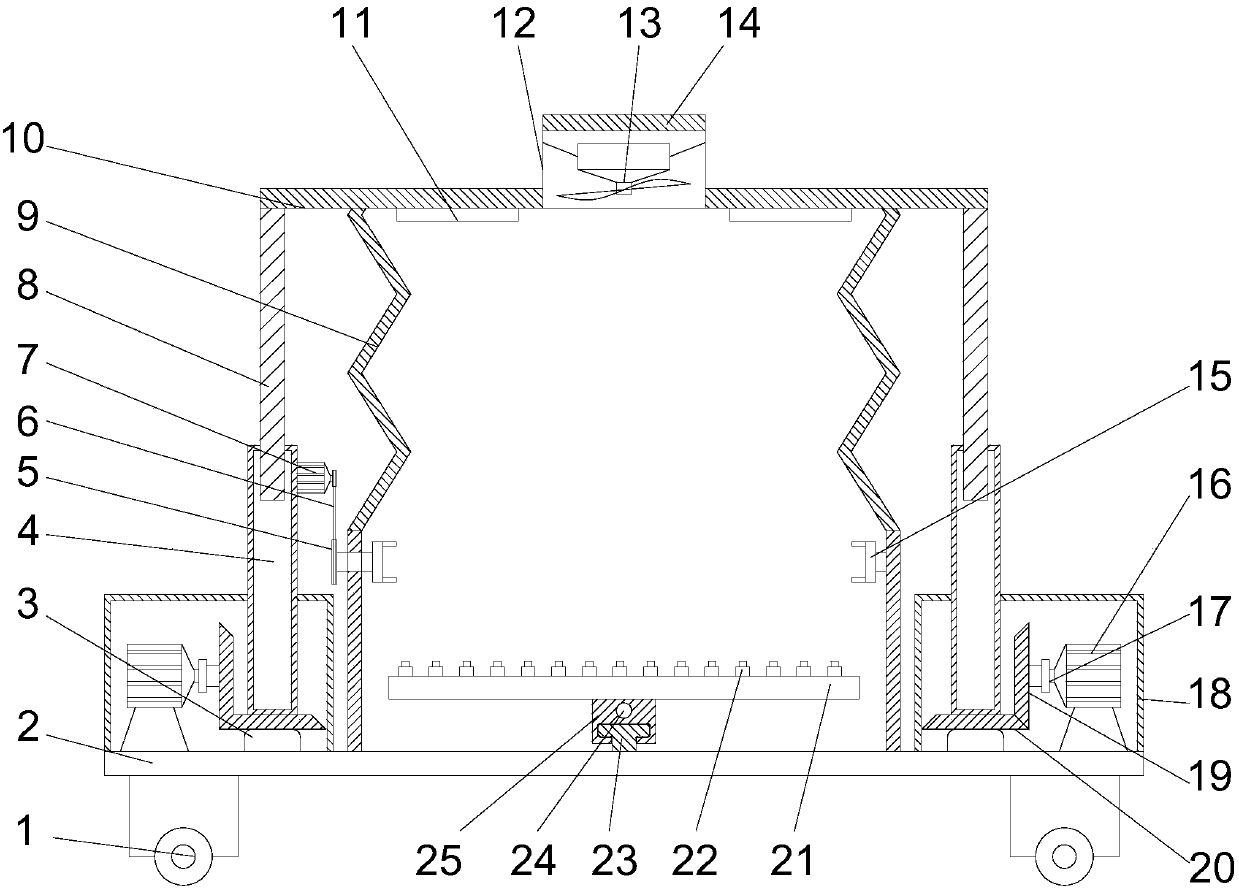

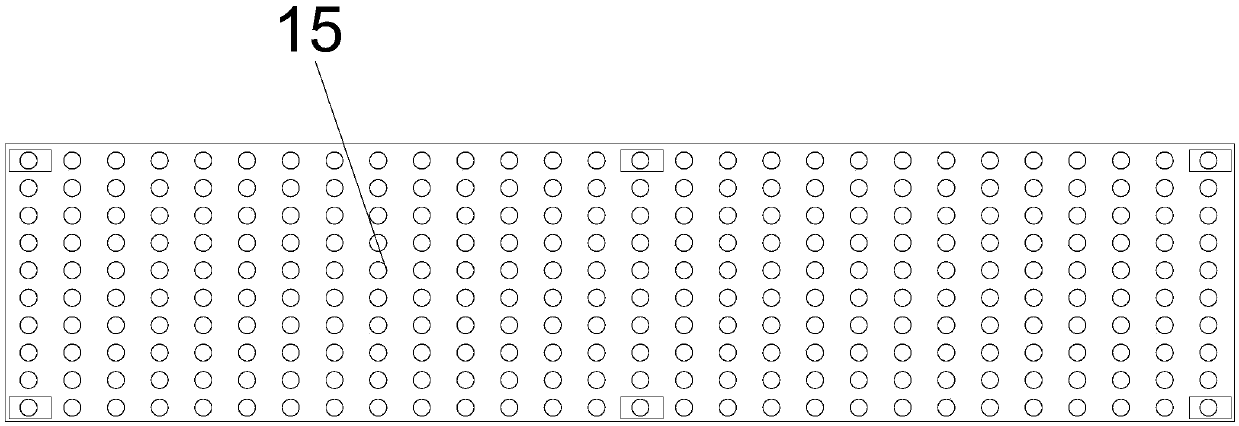

[0014] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a high-efficiency wooden door painting equipment proposed by the present invention; figure 2 It is a schematic structural diagram of the front view of a wooden door fixture of a high-efficiency wooden door spray painting equipment proposed by the present invention.

[0015] refer to Figure 1-2 , a kind of high-efficiency wooden door painting equipment proposed by the present invention, including universal wheel 1, bottom plate 2, telescopic support, pulley 5, belt 6, first motor 7, telescopic side wall board 9, upper cover board 10, heating lamp 11 , air duct 12, fan 13, filter plate 14, wooden door fixture 15, distribution plate 21, nozzle 22, T-shaped guide rail 23, hydraulic telescopic rod 24, chute 25;

[0016] The universal wheel 1 is fixedly installed on the bottom of the base plate 2 by screws; the universal wheel 1 is provided with a locking shaft; the upper side of the base plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap