Binder, method for preparing the binder, and electrode and lithium battery comprising the binder

一种粘合剂、聚合物的技术,应用在粘合剂类型、不饱和醇共聚物粘合剂、胶粘剂等方向,能够解决电极稳定性降低、低初始充电/放电效率、池提供机械性质或粘结强度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0128] According to another embodiment, a lithium battery includes: the first electrode; a second electrode; and an electrolyte between the first electrode and the second electrode. For example, the first electrode may be a positive electrode, and the second electrode may be a negative electrode; or the first electrode may be a negative electrode, and the second electrode may be a positive electrode.

[0129] The lithium battery may be prepared as follows.

[0130] A negative electrode may be prepared by using the negative electrode preparation method, and a positive electrode may be prepared by using the positive electrode preparation method.

[0131] A separator to be provided between the positive electrode and the negative electrode was prepared. The separator for the lithium battery may be any suitable separator used in lithium batteries. In some embodiments, the separator may have low resistance to migration of ions in an electrolyte and have excellent electrolyte holdi...

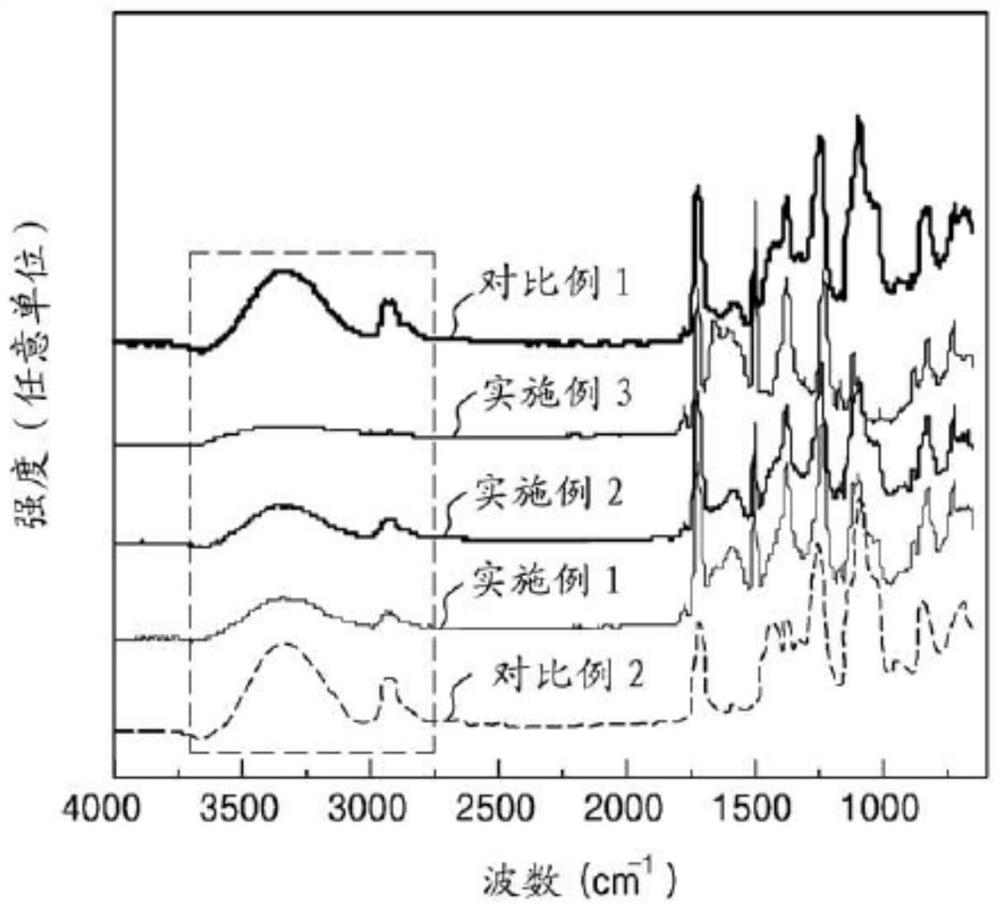

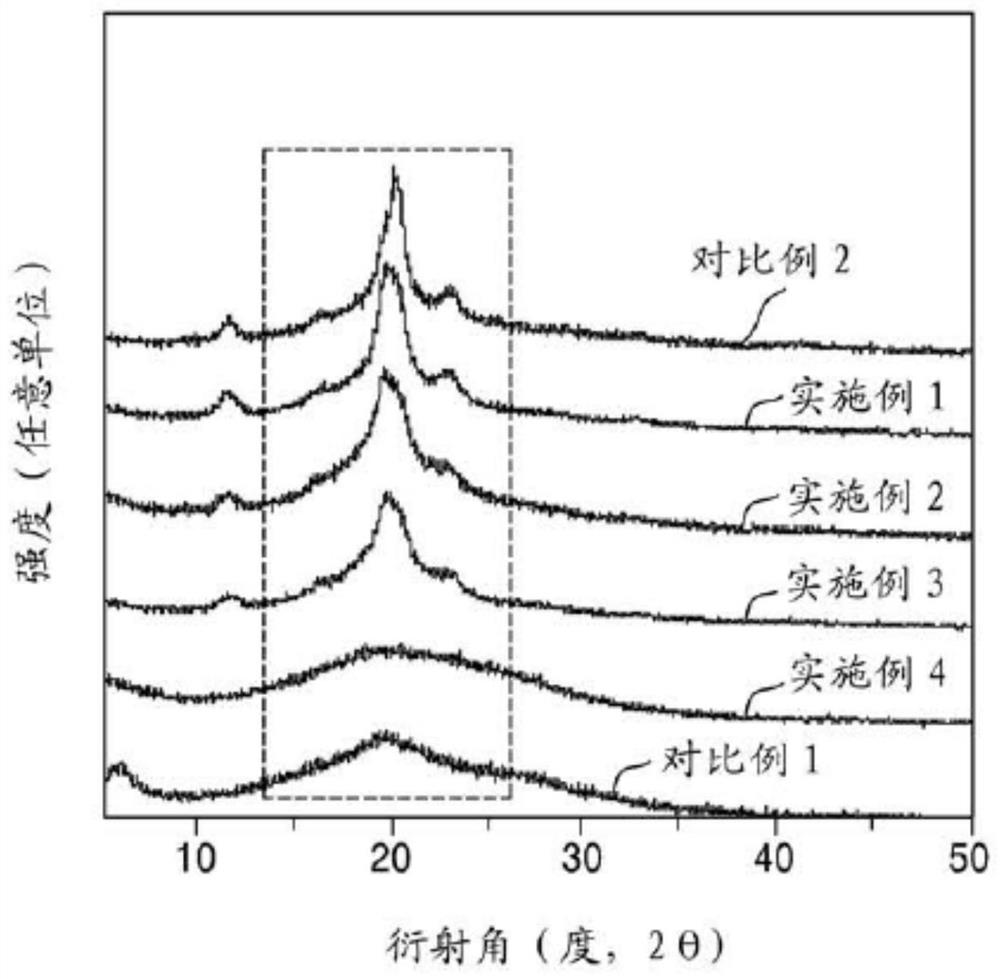

Embodiment 1

[0166] Embodiment 1: LiPI:PVA=10:90

[0167] After the three-neck round bottom flask was filled with nitrogen, 9.9790 g (0.0498 mol) of 4,4'-oxodiphenylamine (ODA) and 2.5275 g (0.0166 mol) of 1,3-diamino Benzoic acid (DABA), to which 153 g of N-methylpyrrolidone (NMP) was added, and the resultant was completely dissolved by using a mechanical stirrer. Then, 14.4935 g (0.0664 mol) of pyromellitic dianhydride (PMDA) was added thereto, and the mixture was stirred at room temperature for 24 hours to prepare polyamic acid (PMDA / ODA / DABA, having 210 g / eq of acid equivalent and a Mw of about 1,000,000 Da). The polyamic acid is a random copolymer. The molar ratio of PMDA:ODA:DABA is 4:3:1. The molar ratio n:m in Formulas 9 and 10 is 3:1.

[0168] To the polyamic acid (PMDA / ODA / DABA, having an acid equivalent of 210 g / eq and a Mw of about 1,000,000 Da) represented by Formula 9, 10 g of LiOH aqueous solution was added at a ratio of 0.5 equivalent to the carboxylic acid to prepare ...

Embodiment 2

[0173] Embodiment 2: LiPI:PVA=20:80

[0174] A crosslinked polymer was prepared in the same manner as in Example 1, except that the water-soluble polyamic acid represented by Formula 10 and the polyvinyl alcohol were mixed in a weight ratio of 20:80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com