Monitoring method used in industrial site

An industrial site and tool technology, applied in the field of monitoring applied to the industrial site, can solve the problem that the display screen cannot display the required information well, and can not solve the problem of the information display of the industrial site, so as to achieve the effect of avoiding danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A chemical factory has an industrial area of 20,000 square meters and a control room. During the inspection process, using this monitoring method, equipment information can be observed at any position next to the equipment, and alarm information and troubleshooting methods can be displayed in time.

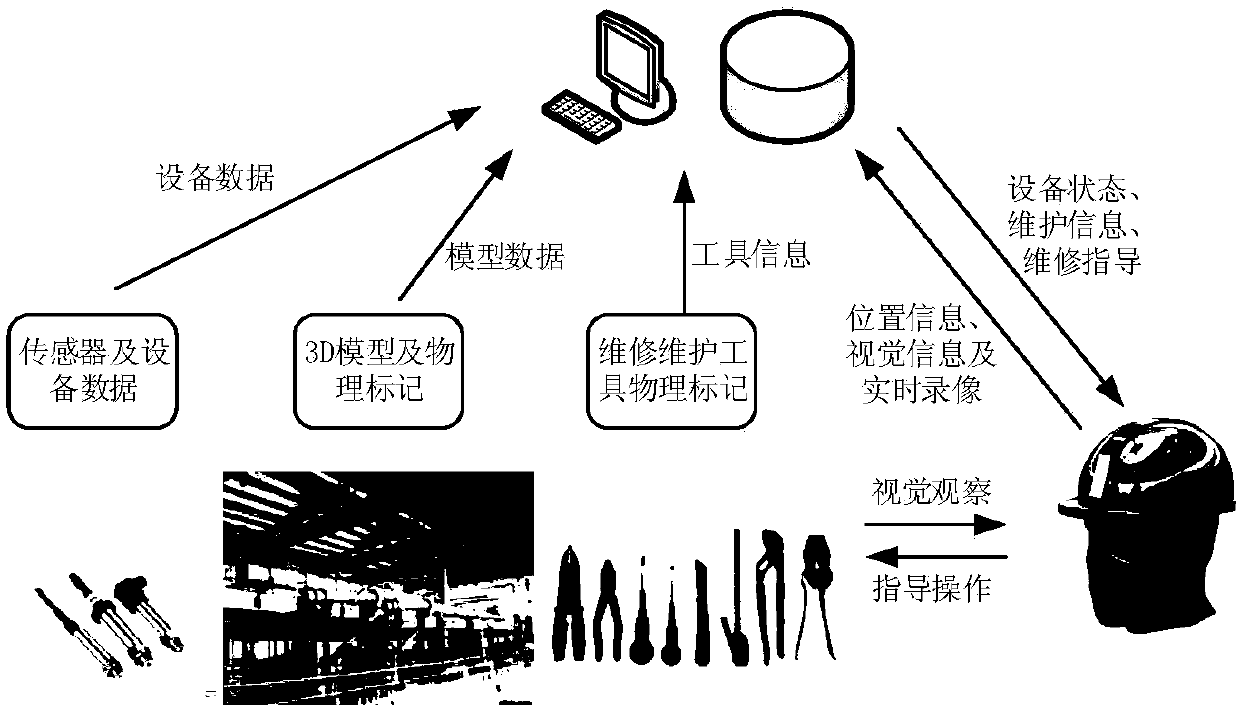

[0014] A monitoring method applied to industrial sites is as follows: using multifunctional glasses and a computer data center, the multifunctional glasses have video recording, positioning, communication, display, storage and calculation functions, and the computer data center stores three-dimensional models of various equipment; When the 3D model is updated, the multifunctional glasses communicate with the computer data center in real time and update automatically; tools and various equipment are marked, and the equipment is marked as color blocks / belts, one-dimensional codes, two-dimensional codes or radio frequency identification tags, tools Marked as color blocks of d...

Embodiment 2

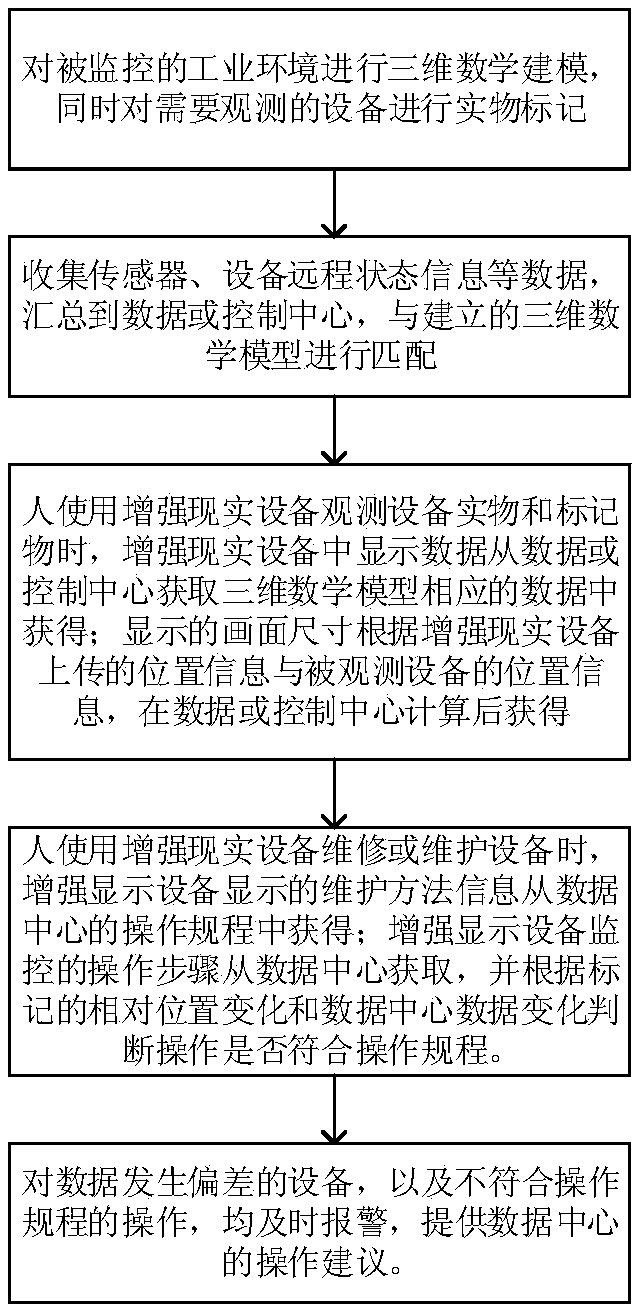

[0019] First, carry out three-dimensional mathematical modeling of the monitored industrial site, store it in the data center, and at the same time mark the physical objects of the observed equipment; secondly, collect the monitored data such as sensors and equipment remote status information, and summarize them in the data center, and establish The 3D mathematical model is matched and marked in the 3D model; the multifunctional glasses are used to observe the real object and markers of the equipment, and the multifunctional glasses obtain the data collected by the sensor corresponding to the 3D mathematical model from the data center and display it in the visual image; The display device calculates the current location based on the image size of the marked object, and at the same time calculates the size of the screen to be displayed based on the current location and the display target location; when the augmented reality device obtains the data center alarm device information,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com