Flange guide rod pressing and connecting tool

A technology of guide rods and flanges, which is applied in the field of process equipment in the production process of automobile fuel tanks, and can solve problems such as inability to realize pressure control and displacement control, low pressure application efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

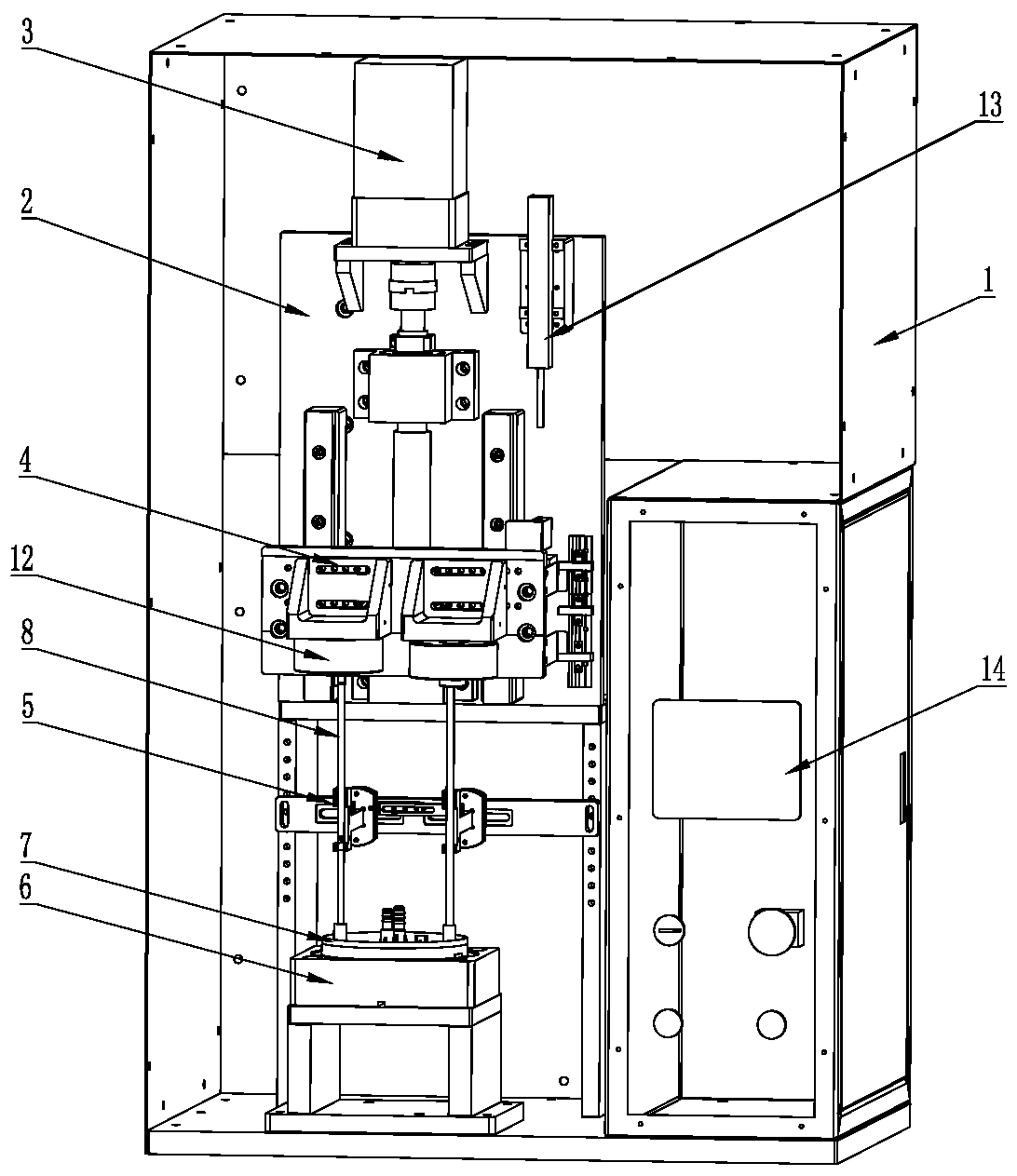

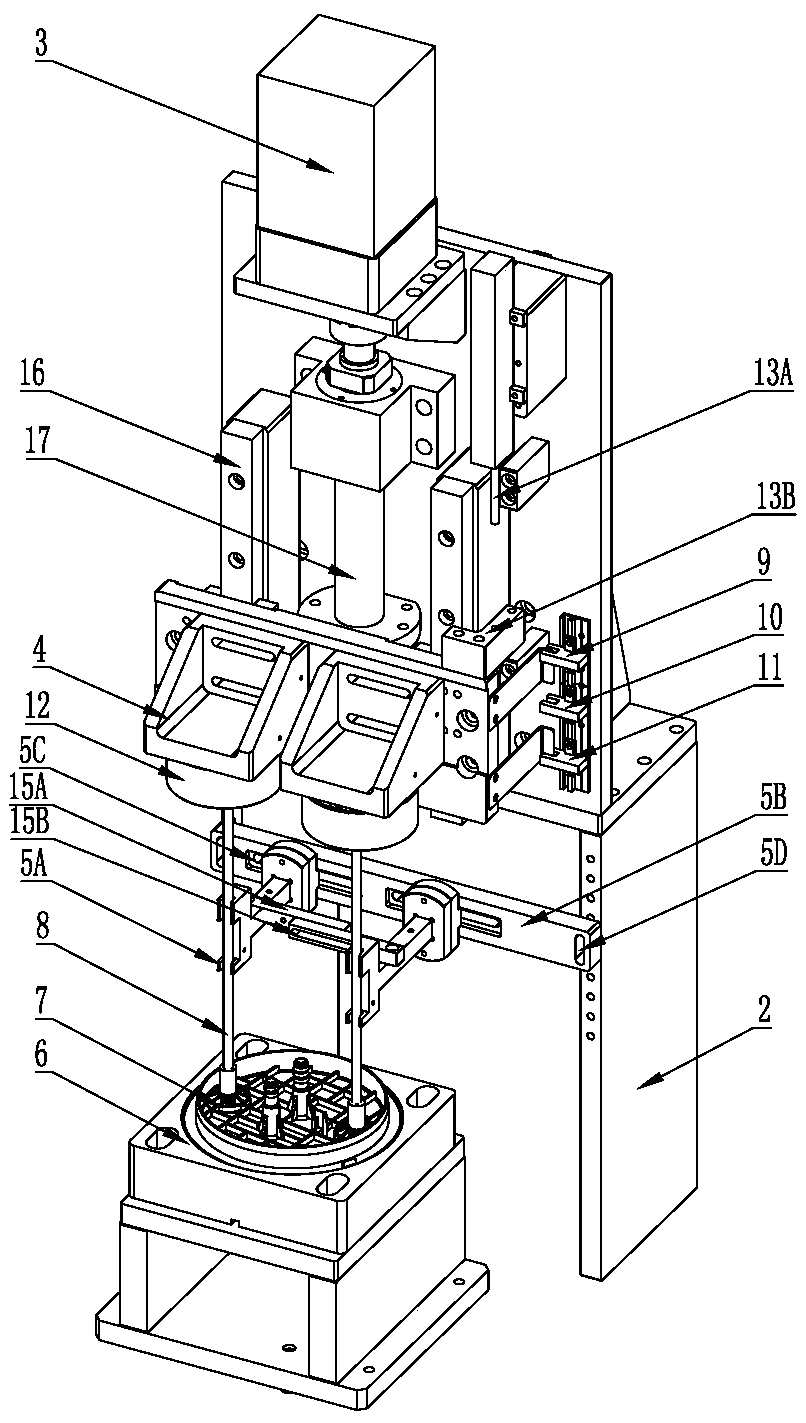

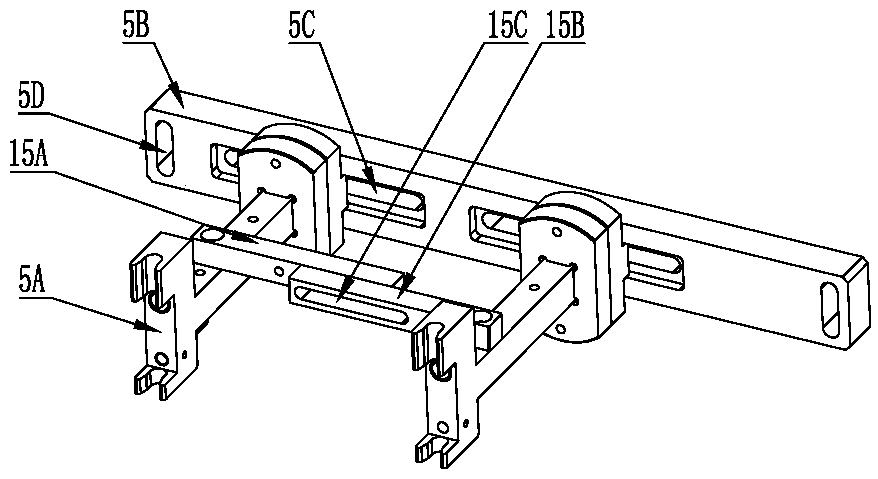

[0019] Such as figure 1 The shown flange guide rod crimping tool is fixed in the outer protective shell 1, and the outer protective shell 1 is provided with a bracket 2, and the stepping motor 3, The pressure applying device 4, the guide rod fixing device 5, and the flange fixing base 6 are arranged at the bottom of the bracket. The lower part of the front end of the housing 1 is open ( figure 1 In order to show the internal structure, the shell covering part of the front end surface is omitted to facilitate the insertion of the flange 7 and the guide rod 8. The output end of the stepping motor 3 is provided with a screw mandrel 17 . The upper end of the pressure applying device 4 is connected with the screw rod 17, the rear end of the pressure applying device 4 is slidingly connected with the longitudinal slide rail 16 arranged on the bracket 2, the guide rod fixing device 5 can keep the guide rod 8 in a vertical state, and the flange 7 is fixed When the flange is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com