Fast-assembling mechanism for wings of unmanned aerial vehicle

A technology of unmanned aerial vehicles and wings, applied in the directions of wings, fuselage, aircraft parts, etc., can solve the problems such as the need for other tools for disassembly and assembly, and the time-consuming disassembly and assembly, so as to facilitate field operations, and facilitate assembly and disassembly. The effect of repair and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

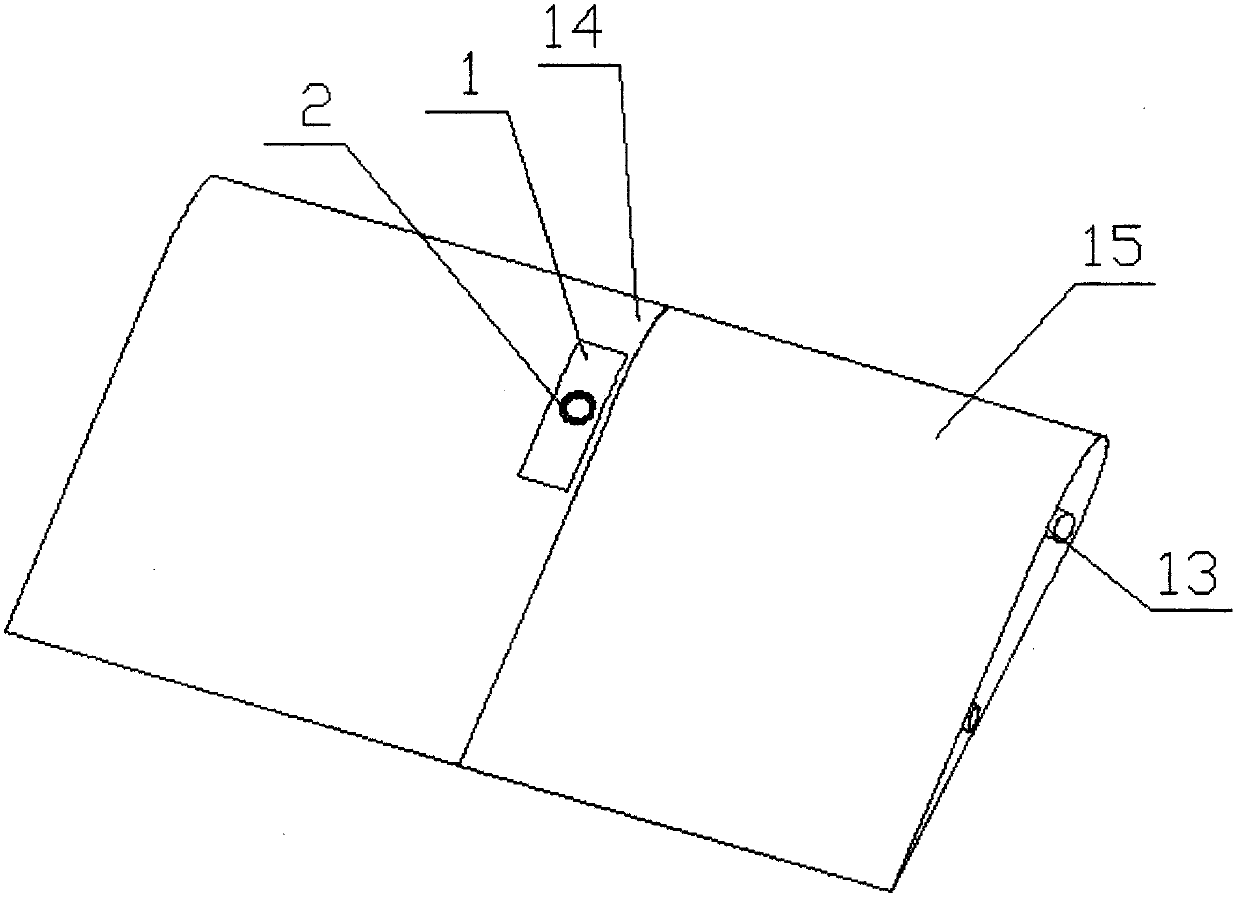

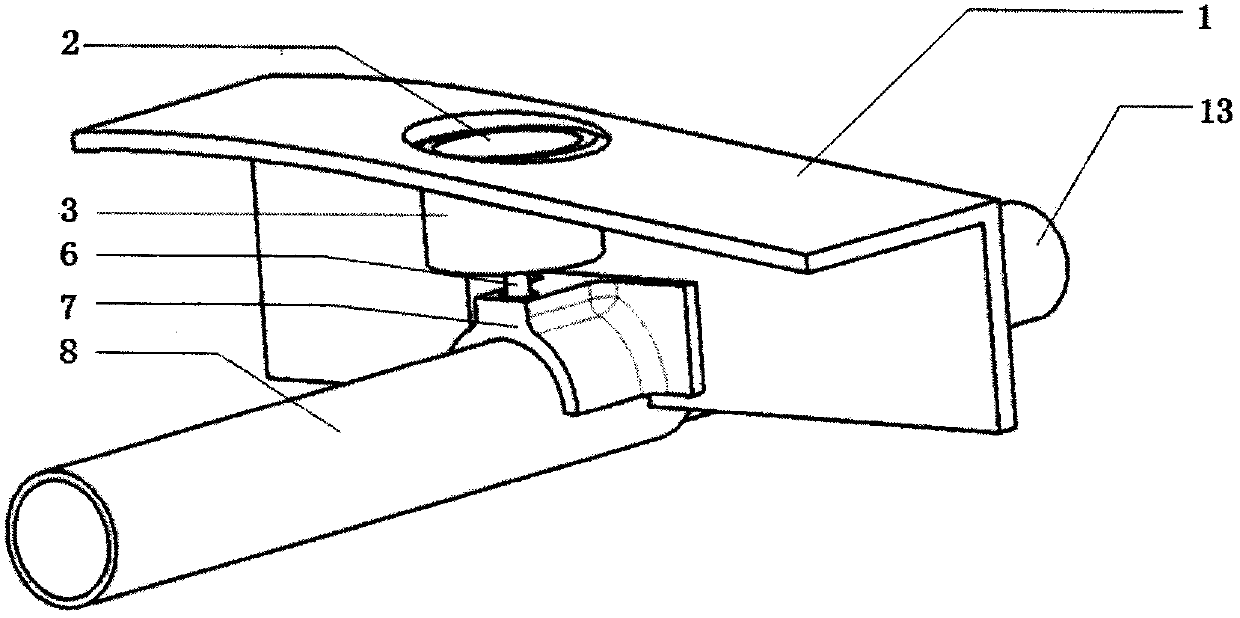

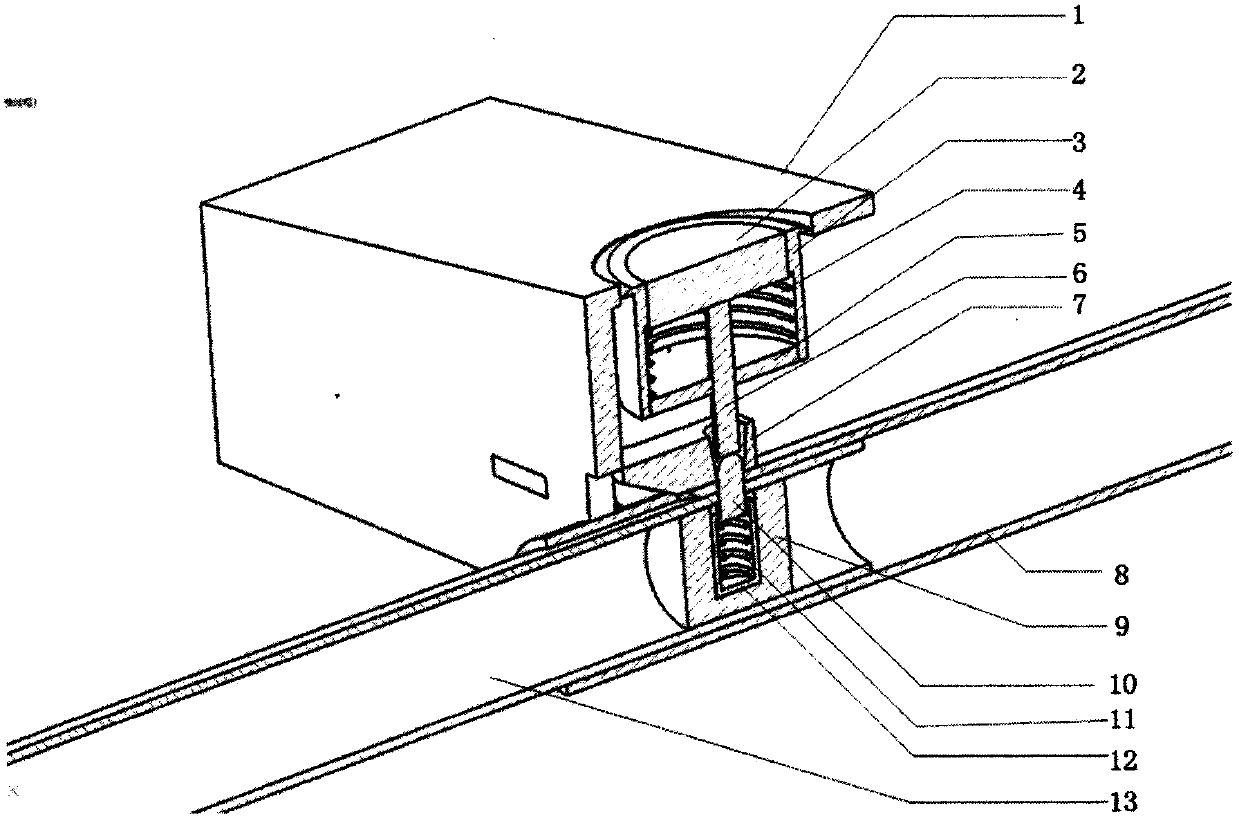

Embodiment 1

[0025] Such as Figure 1-5 As shown, the present invention provides a quick-installation mechanism for UAV wings, including a frame 1, a button 2, a button shell 3, a button spring 4, a button base 5, a button thimble 6, a fixed block 7, a thick carbon tube 8, a spring Pin seat 9, spring pin 10, pin spring 11, spring pin housing 12, thin carbon tube 13, inner section wing 14 and outer section wing 15, one side of inner section wing 14 is provided with outer section wing 15, The middle part of the inner wing 14 is provided with a frame 1, the middle part of the frame 1 is provided with a button 2, one side of the frame 1 is provided with a thick carbon tube 8, the other side of the frame 1 is provided with a thin carbon tube 13, and the thick carbon tube 8 The top of the fixed block 7 is provided with a fixed block 7, the top of the fixed block 7 is provided with a button thimble 6, the top of the button thimble 6 is provided with a button shell 3, the inside of the button shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com