Preparation method and application of a molecularly imprinted composite sponge membrane for selective separation of emodin

A composite sponge and molecular imprinting technology, which is applied in the fields of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of small flow rate and low flow rate of molecular imprinted membranes, and achieve difficult recovery, high flow rate, and improved utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] S1. Preparation of graphene oxide modified sponge membrane

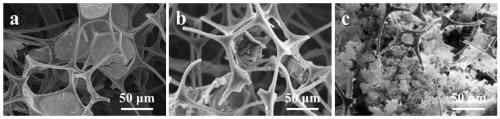

[0045] First, the commercially available melamine sponge was cut into thin slices (15 mm×7 mm×5 mm), soaked in deionized water and ethanol for ultrasonic cleaning; then, 10 pieces of cleaned melamine sponge membranes were soaked in 50 mL concentration 1 mg / mL graphene oxide solution, ultrasonic treatment for 30 min; thereafter, the impregnated sponge membrane was taken out, centrifuged at 3000 rpm for 1 min, and dried at 60°C to obtain graphite oxide olefin modified sponge membranes (GO@MSMs). The resulting GO@MSMs scan is similar to the GO@MSMs scan in Example 2, by figure 1 (a) It can be seen that graphene oxide sheets are successfully loaded in the sponge skeleton.

[0046] S2, preparation of activated composite sponge membrane

[0047] First, 6 sheets of graphene oxide-modified sponge membranes (GO@MSMs) obtained in step 1 were immersed in a mixed solution of 100 mL ethanol and water (ethanol: water = 8...

Embodiment 2

[0054] S1. Preparation of graphene oxide modified sponge membrane

[0055] First, the commercially available melamine sponge was cut into thin slices (15 mm×7 mm×5 mm), soaked in deionized water and ethanol for ultrasonic cleaning; then, 10 pieces of cleaned melamine sponge membranes were soaked in 50 mL concentration 2.6 mg / mL graphene oxide solution, ultrasonic treatment for 30 min; thereafter, the impregnated sponge membrane was taken out, centrifuged at 3000 rpm for 1 min, and dried at 60°C to obtain graphene oxide Modified sponge membranes (GO@MSMs). The obtained GO@MSMs scan image is as follows figure 1 As shown in (a), it can be seen that graphene oxide sheets are successfully loaded in the sponge skeleton.

[0056] S2, preparation of activated composite sponge membrane

[0057] First, 6 sheets of graphene oxide-modified sponge membranes (GO@MSMs) obtained in step 1 were immersed in a mixed solution of 100 mL ethanol and water (ethanol: water = 80 mL: 20 mL), and the...

Embodiment 3

[0064] S1. Preparation of graphene oxide modified sponge membrane

[0065]First, the commercially available melamine sponge was cut into thin slices (15 mm×7 mm×5 mm), soaked in deionized water and ethanol for ultrasonic cleaning; then, 10 pieces of cleaned melamine sponge membranes were soaked in 50 mL concentration 5 mg / mL graphene oxide solution, sonicated for 30 min; thereafter, the impregnated sponge membrane was taken out, centrifuged at 3000 rpm for 1 min, and dried at 60°C to obtain graphite oxide olefin-modified sponge membranes (GO@MSMs). The resulting GO@MSMs scan is similar to the GO@MSMs scan in Example 2, by figure 1 (a) It can be seen that graphene oxide sheets are successfully loaded in the sponge skeleton.

[0066] S2, preparation of activated composite sponge membrane

[0067] First, 6 sheets of graphene oxide-modified sponge membranes (GO@MSMs) obtained in step 1 were immersed in a mixed solution of 100 mL ethanol and water (ethanol: water = 80 mL: 20 mL)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com