Engineering equipment monitoring device

A technology of engineering equipment and monitoring device, applied in the field of equipment monitoring, can solve the problems of lack of contact between engineering enterprises, lack of monitoring and deployment of engineering equipment, and inability to obtain specific conditions of engineering equipment, so as to reduce monitoring costs and facilitate understanding and tracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0013] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

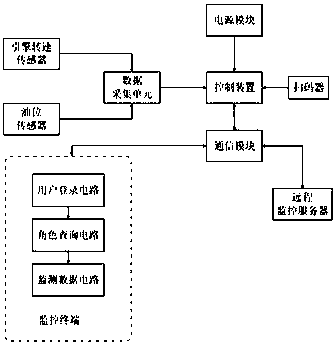

[0014] Such as figure 1 As shown, the engineering equipment monitoring device includes a power supply module, a monitoring device, a control device, a communication module and a monitoring terminal. The monitoring device is used to monitor the operation of the engineering equipment, and the control device is used to analyze and process the equipment collected by the monitoring device. data, the monitoring terminal is used for the user to understand and track the monitored engineering equipment in real time. The monitoring device includes a code scanner, an engine speed sensor, an oil level sensor and a data acquisition unit. The engine speed sensor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com