Macrosegregation prediction method of continuous casting slab

A technology of macro-segregation and prediction method, which is applied in the direction of prediction, data processing applications, instruments, etc., can solve the problems of low efficiency, high cost, and inability to obtain the distribution of solute and inclusions in complete detail, so as to control the quality of continuous casting slabs , Continuous casting slab solute macro-segregation prediction results are accurate and reasonable, and the effect of improving solute macro-segregation distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical scheme of the present invention is described in detail below:

[0063] A continuous casting slab macro segregation prediction method, comprising the following steps:

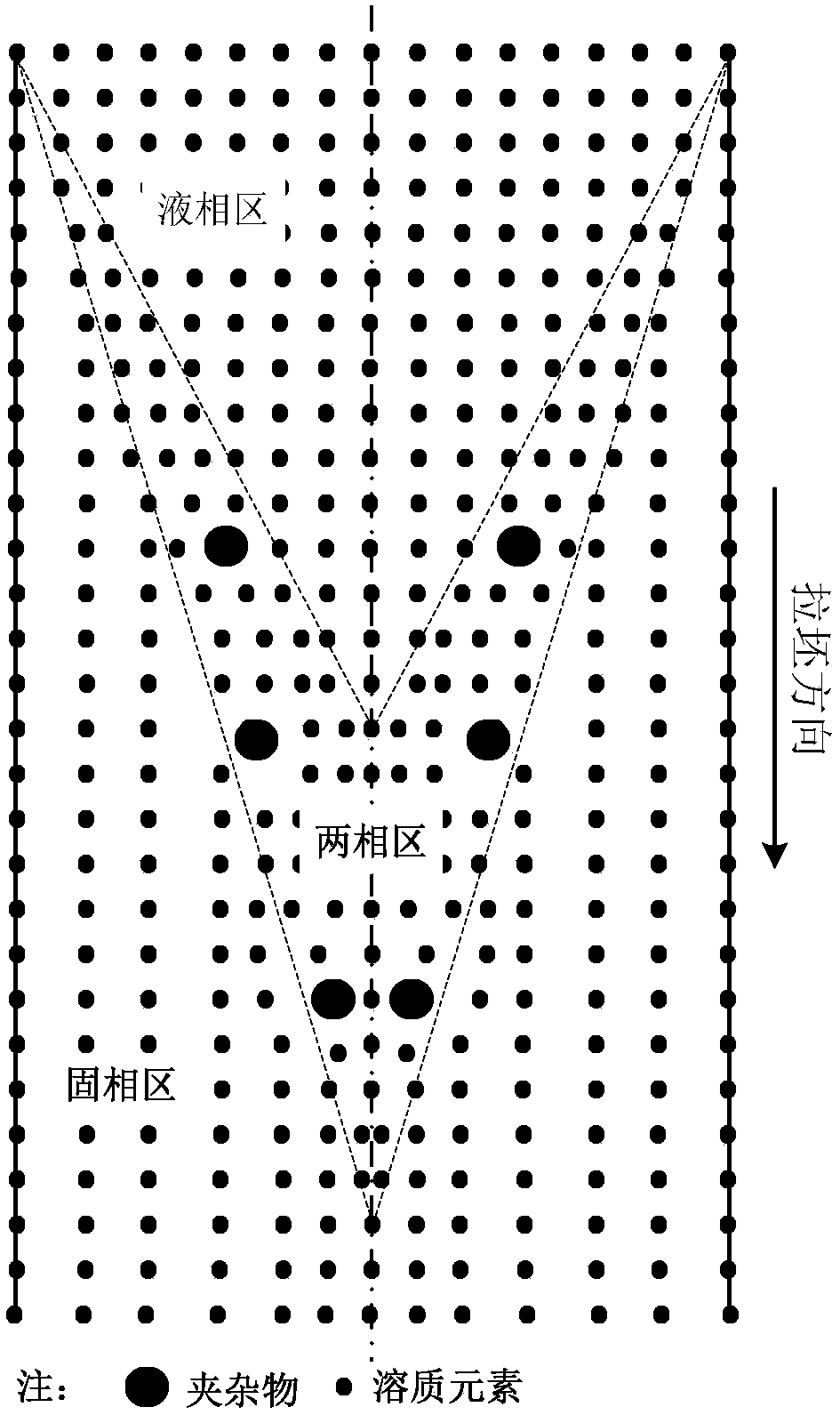

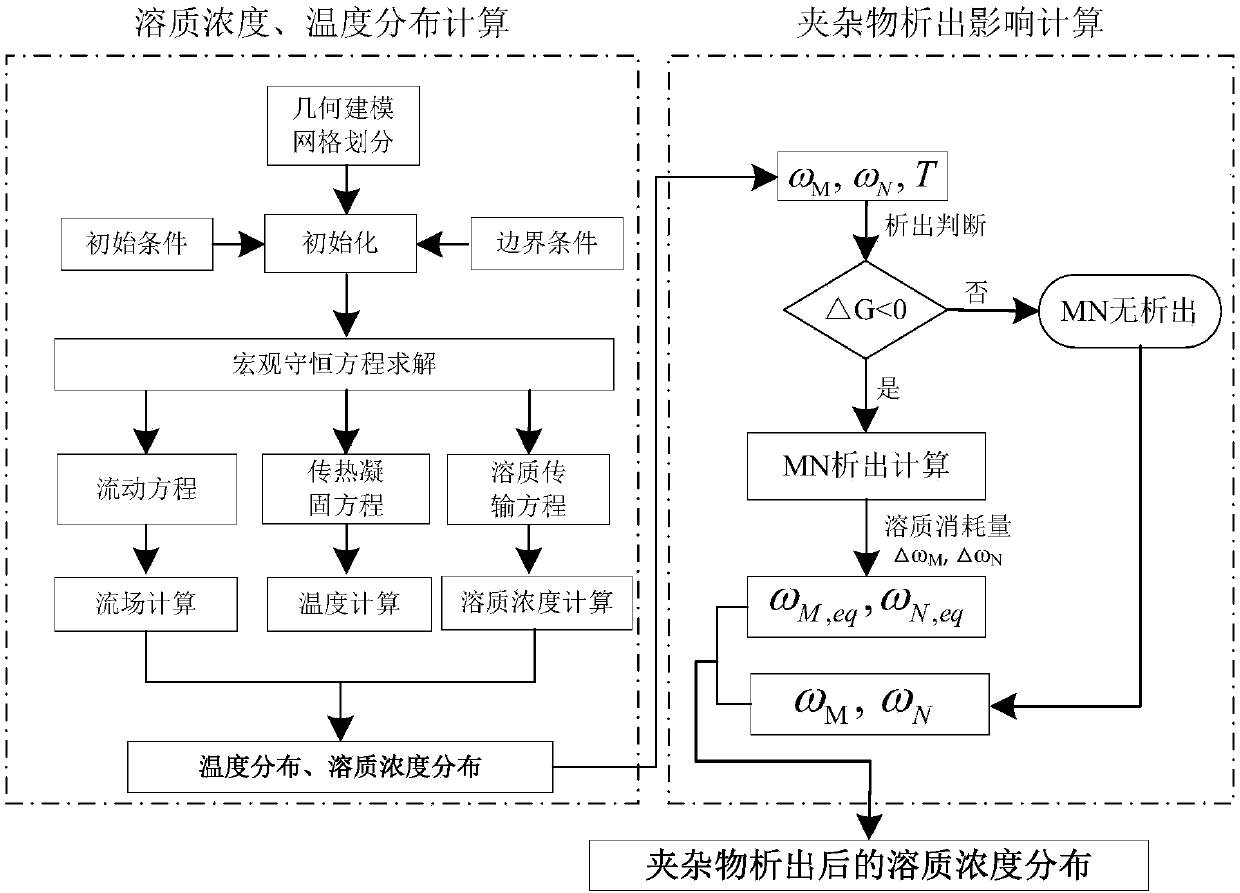

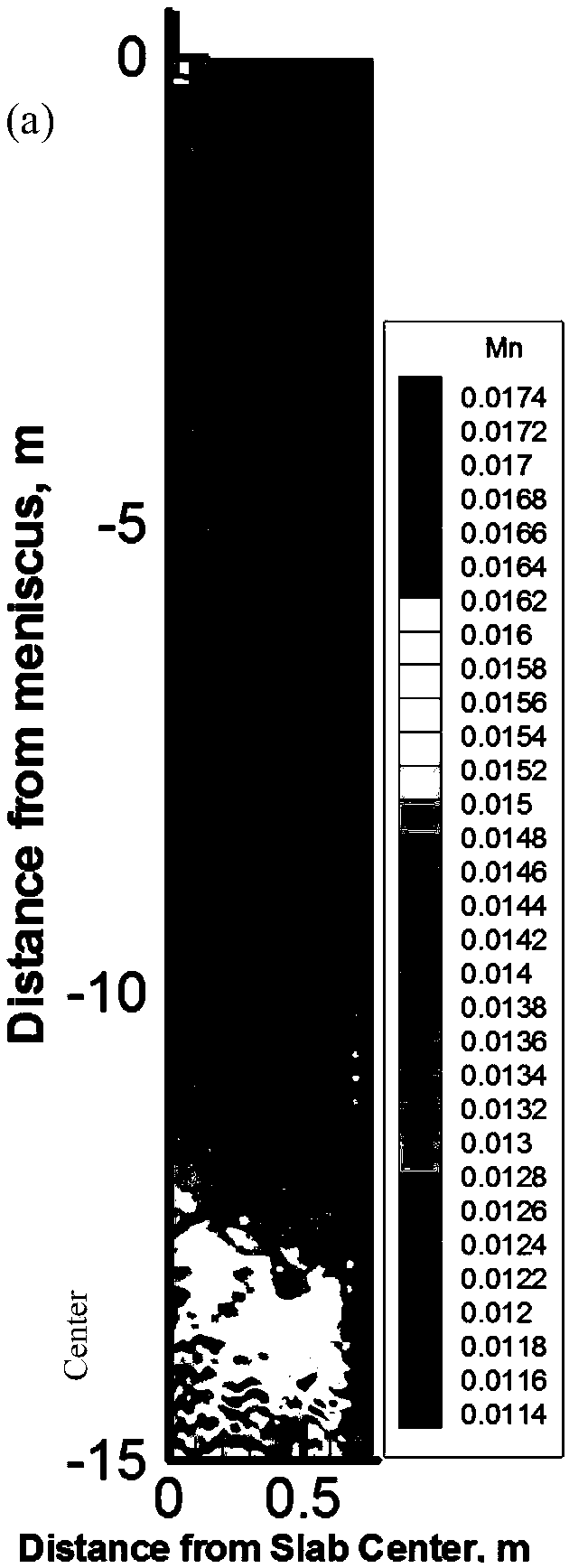

[0064] The first step is to establish a continuous casting solidification macro-segregation model to obtain the solute concentration distribution and temperature distribution in the continuous casting slab when the precipitation of inclusions is not considered;

[0065] In the second step, based on the solute concentration distribution and temperature distribution in the continuous casting slab in the first step, the calculation model of inclusion precipitation is introduced; according to the thermodynamic theory of inclusion precipitation and the law of solute mass conservation, the calculation and acquisition of inclusions in the slab The distribution of precipitation, and the consumption of solute by the precipitation of inclusions, etc.;

[0066] The third step, based on the calculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com