Elastic piece connector

A technology of connectors and shrapnel, which is applied in the direction of connection, parts of connecting devices, contact parts, etc., can solve the problems of small elastic force, unfavorable signal transmission, and affecting the contact of shrapnel, and achieve large elastic force, compact structure design, and plastic resistance The effect of strong deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

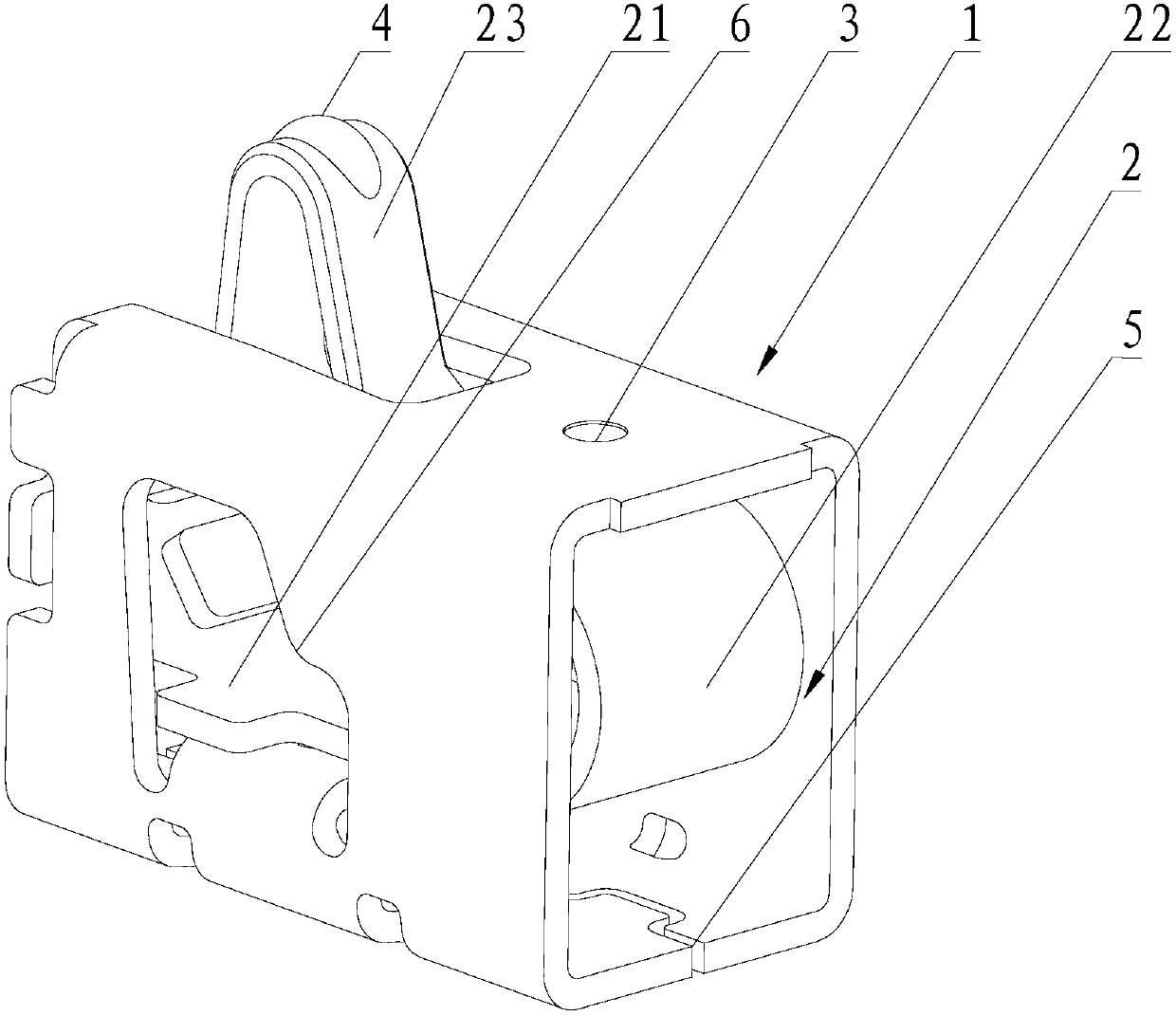

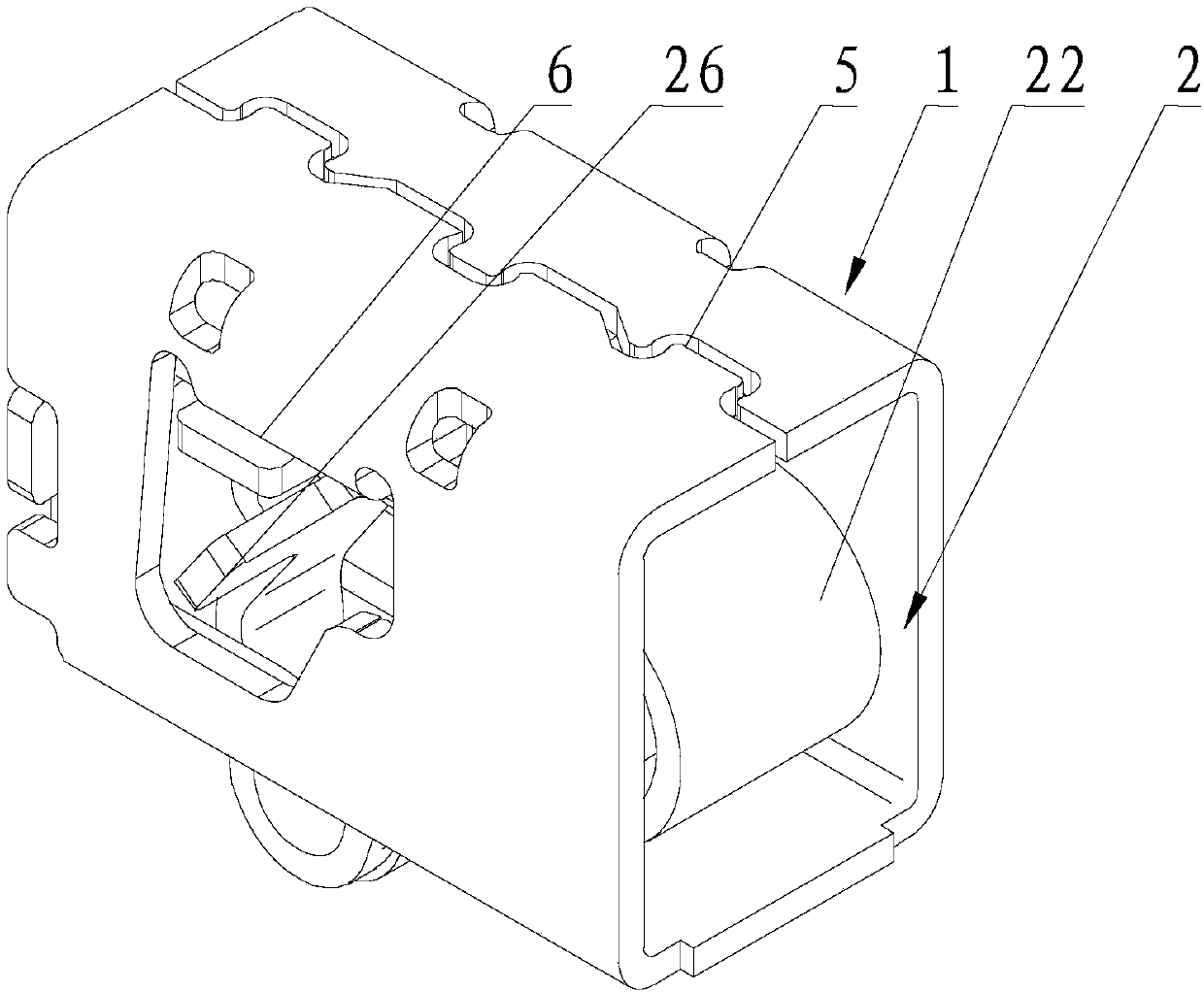

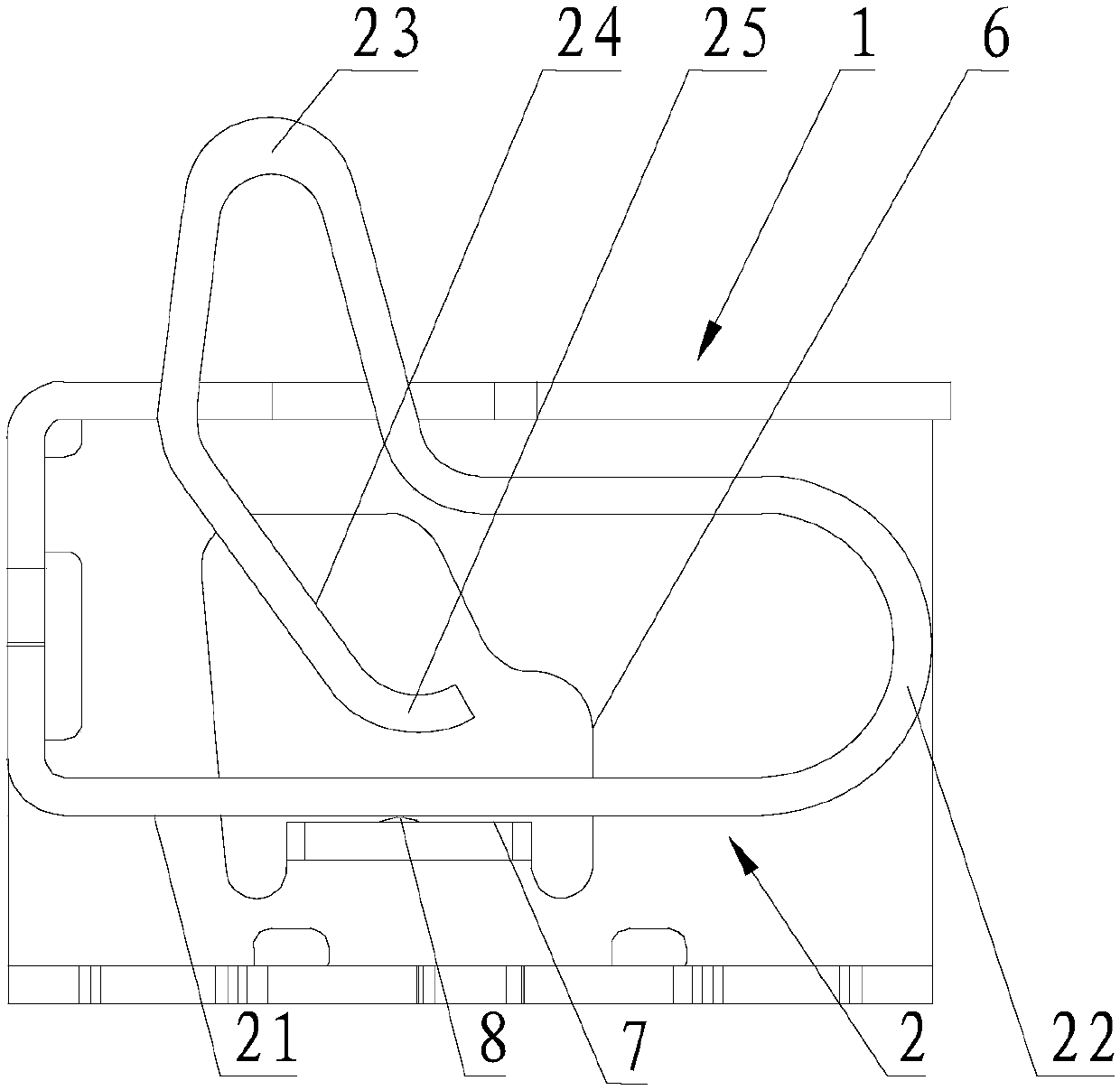

[0040] Please refer to Figure 1-4 , Embodiment 1 of the present invention is:

[0041] A shrapnel connector, comprising a box body 1 and a shrapnel 2 arranged in the box body 1,

[0042] The box body 1 is a hollow structure, the top of the box body 1 is provided with an opening, the box body 1 is provided with a support surface 7, and the support surface 7 is arranged between two opposite sides of the box body 1 , the two side faces provided with the supporting surface 7 are respectively provided with limiting holes 6, and both sides of the supporting surface 7 are respectively connected with the limiting holes 6. The upper surface of the supporting surface 7 is provided with a second protrusion 8 .

[0043] The bottom of the box body 1 is provided with a welding surface, the welding surface is provided with a groove 5, the top of the box body 1 is provided with a marking area 3, and the other two sides of the box body 1 are open.

[0044] The elastic piece 2 includes a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com