Apparatus And Method For The Optical Detection Of Inner Walls

An optical detection and optical imaging technology, which is applied in the direction of using optical devices, measuring devices, and material analysis through optical means, can solve the problems that are not suitable for full-plane 100% detection, and cannot be clearly distinguished from coloring and brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

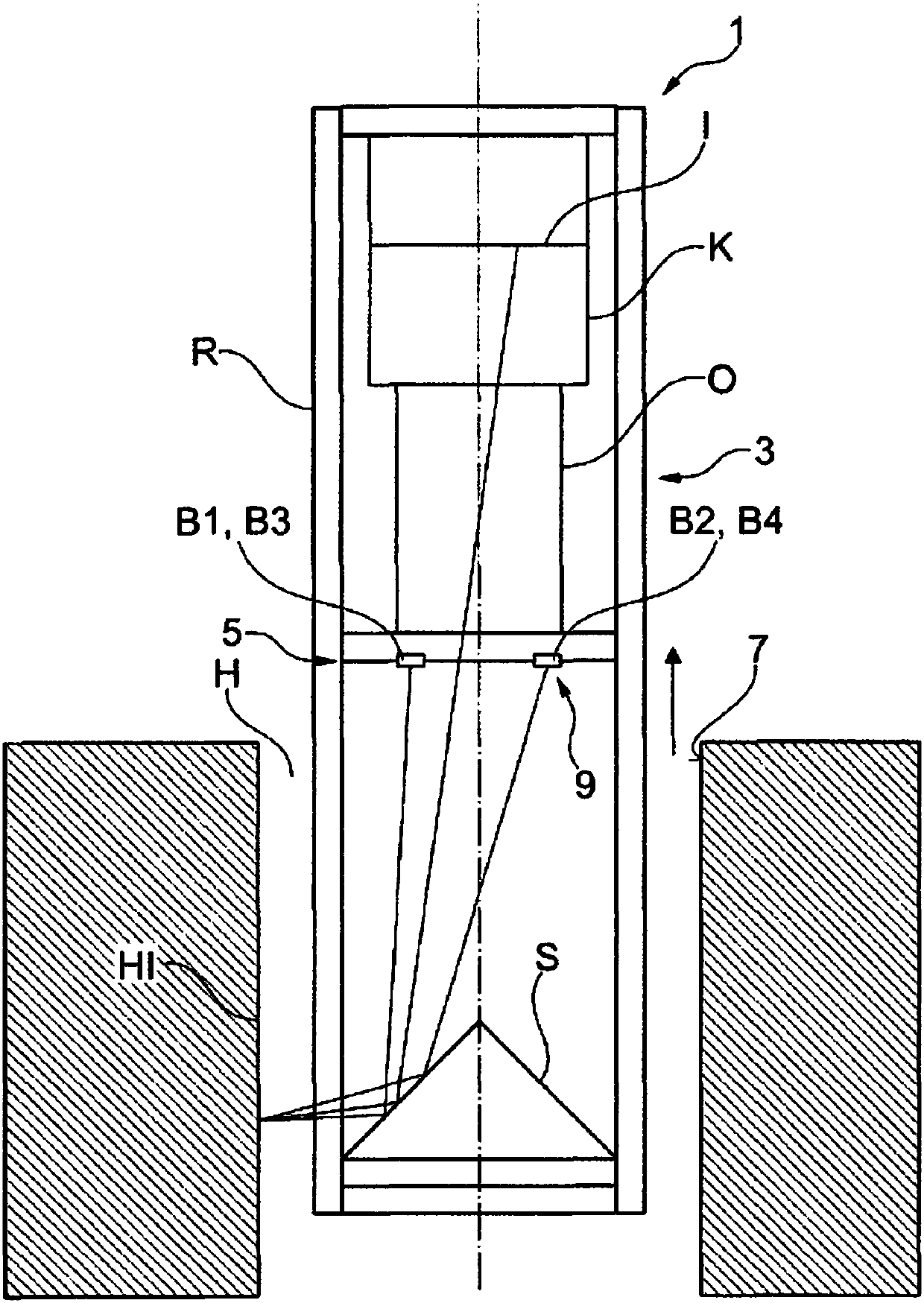

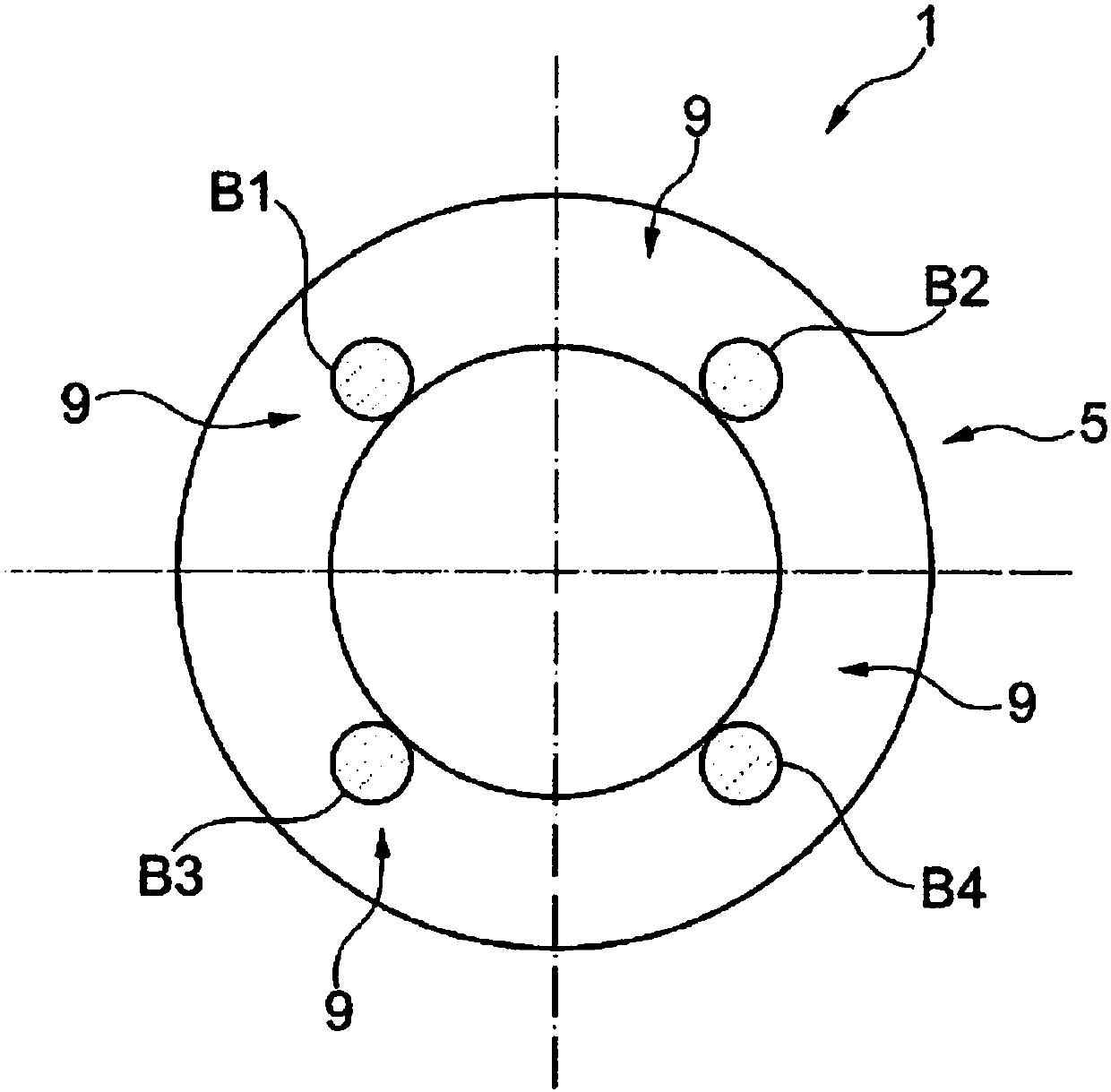

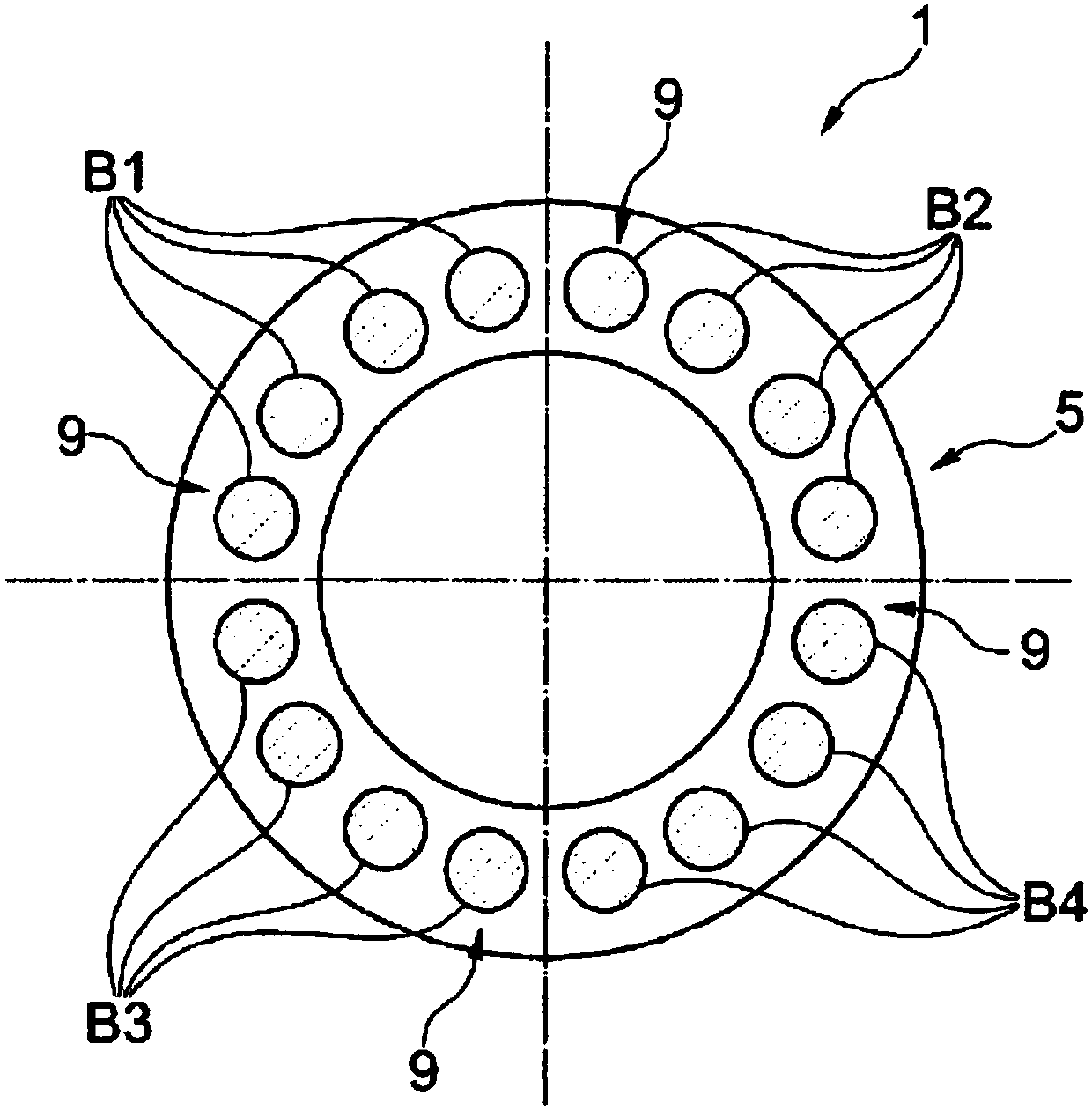

[0059] figure 1 Shows a side view of a device 1 comprising a camera K, an imaging device 3 with a camera objective O and a conical mirror S, and an illumination device 5 with n=4 light sources 9, also called illuminators B1, B2 , ... all the way to Bn. In the example shown, the conical mirror S has an opening angle of 90°. Furthermore the device 1 comprises a cylindrical tube R which houses the aforementioned optical elements and which is transparent in at least one region, preferably in the region where the illumination light path and / or the observation light path pass. Preferably the entire device 1, hereinafter also referred to as arrangement, is first inserted into the borehole or cavity H by means of a device not shown in the figure until the desired position is reached, and then further in the direction of the arrow Back to sports. Cameras can optionally be performed during insertion and / or removal of the borehole. The imaging is preferably carried out during removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com