Automatic forming machine for iron wire frames

An automatic forming machine and wire rack technology, applied in other home appliances, home appliances, applications, etc., can solve the problems of multiple fixed wires, multiple human resources, and more time, saving time, solving more time-consuming, and improving The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

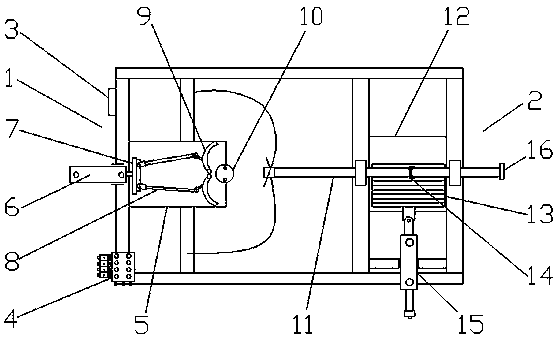

[0022] As a preferred embodiment of the present invention, the bottom of the shaping plate 5 is provided with a bracket, and the two ends of the bracket are provided with welded and fixed steel bars, and the steel bars extend to the top and bottom of the sliding shaft 11 respectively. end. The steel bar plays the role of upper and lower limit during the advancing process of the sliding shaft. If the steel bar shakes continuously during the pushing process of the sliding shaft, it proves that the sliding shaft is loose, and the limiter needs to be checked and re-fixed.

[0023] As a preferred embodiment of the present invention, the sliding shaft 11 is provided with a limiting body, and there are two limiting bodies, which are welded and fixed with the frame of the body. The limit body ensures that the sliding shaft will not deviate left and right during the advancing process, and ensures the qualified rate of iron wire forming.

[0024] As a preferred embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com