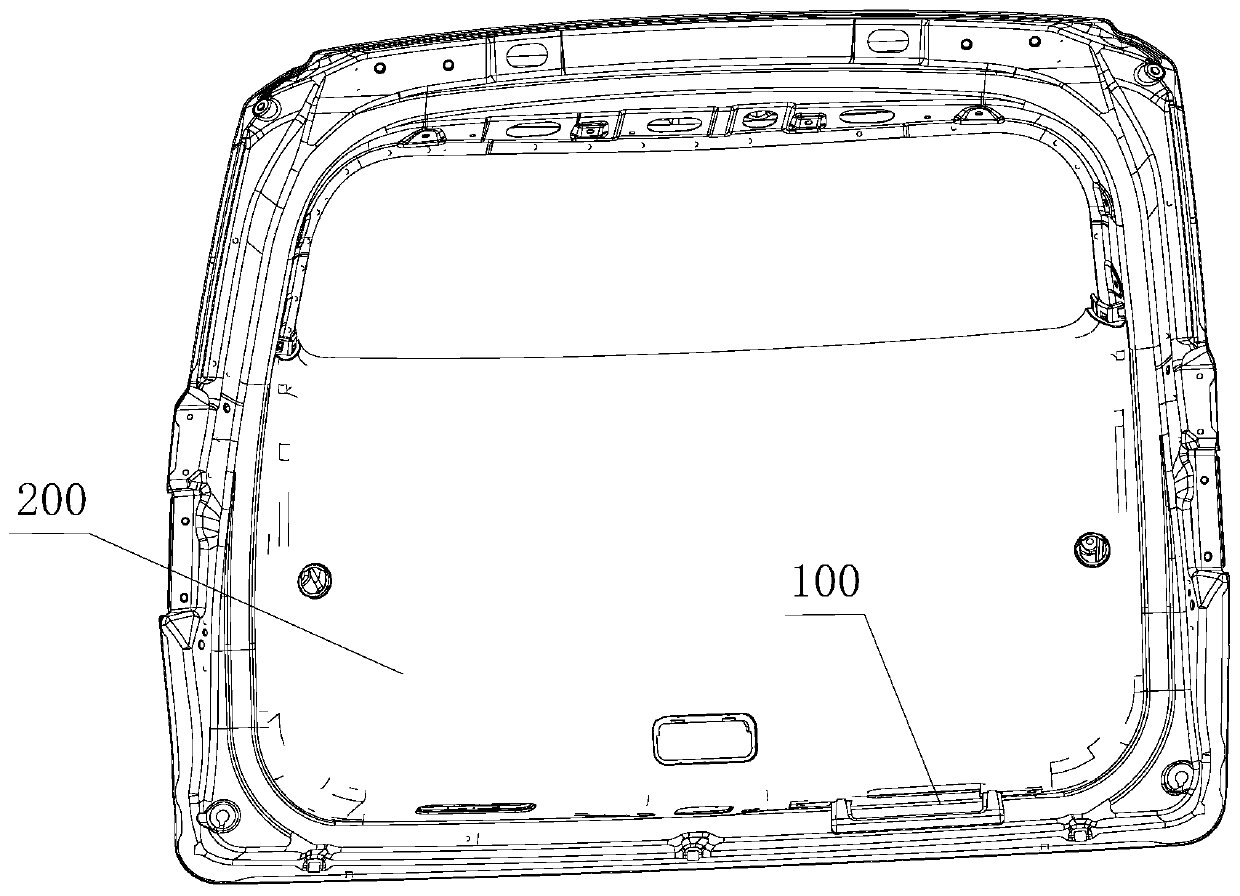

Handle assemblies and vehicles for vehicles

An assembly and vehicle technology, which is applied in the field of SUV vehicles and the handle structure of the vehicle's back door, can solve the problems of not being able to easily grasp the back door handle and easily cause complaints, so as to improve driving comfort and enhance The effect of vehicle quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

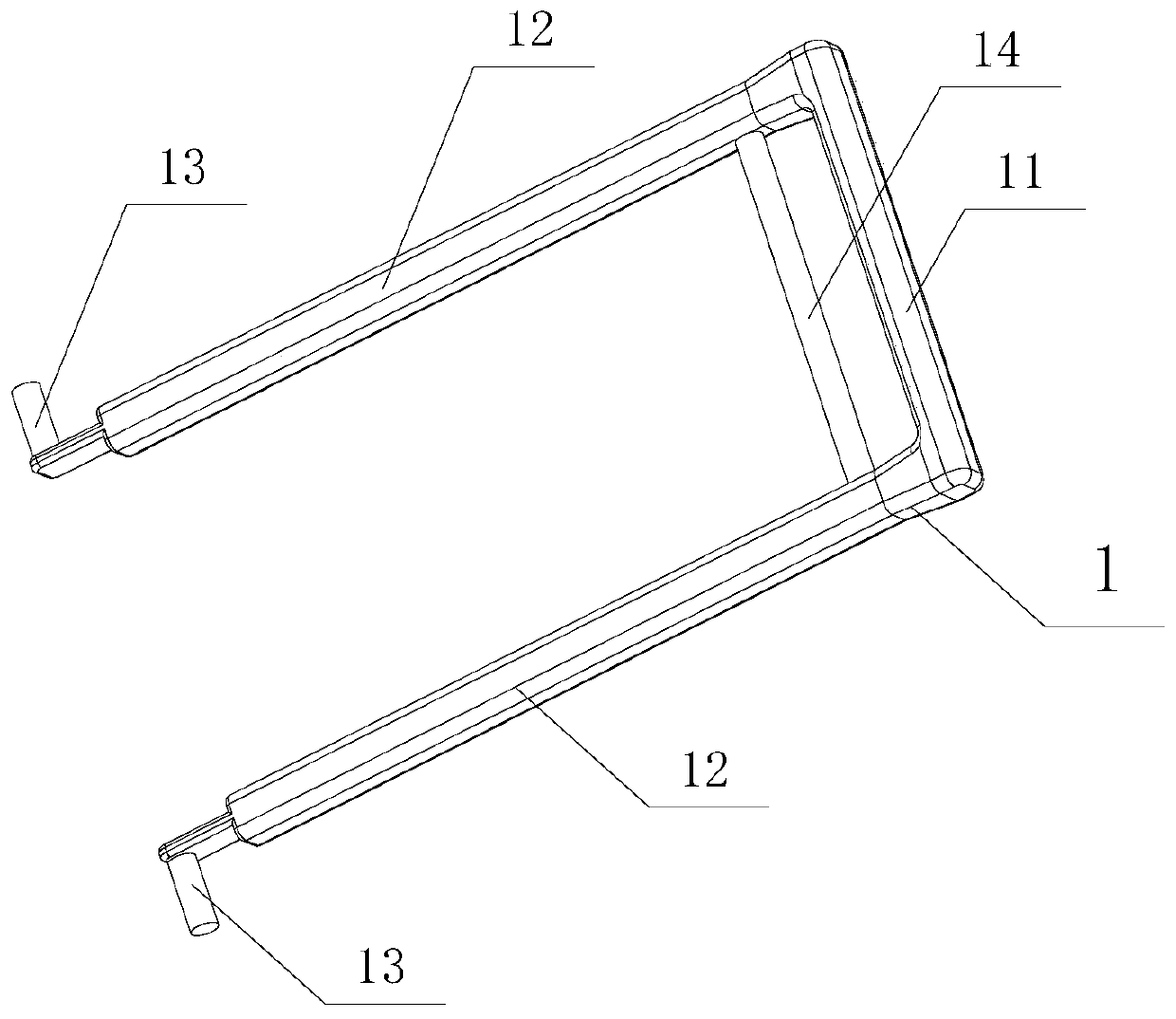

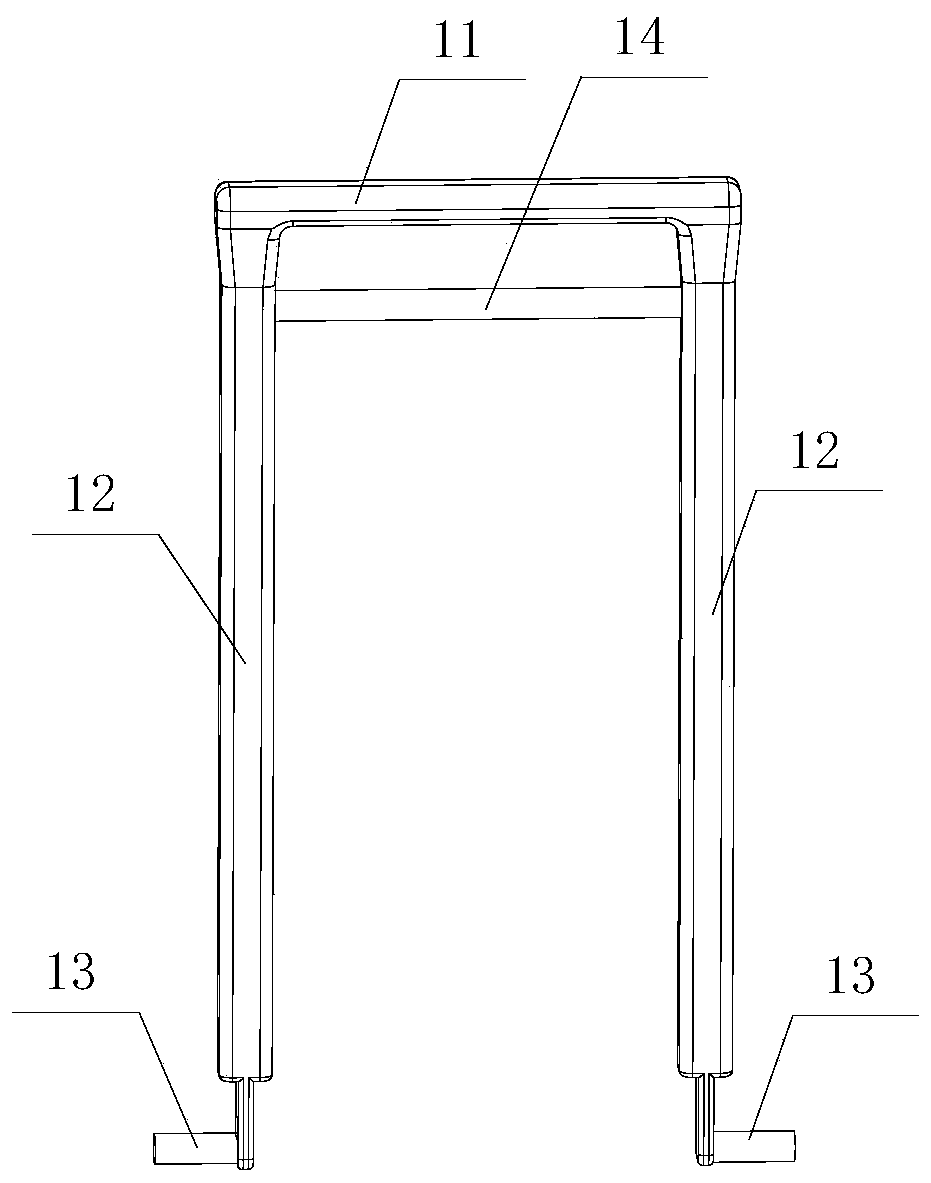

[0043] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0044] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0045] In the present invention, unless otherwise stated, the orientation words used such as "front and rear" are usually relative to the position of the operator who operates the handle assembly as the reference origin to describe the mutual positional relationship of each component. , for example, during operation, the horizontal handle in the handle body is closer to the operator than the rotating column, so one end of the horizontal handle is the front end of the handle body, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com