Specific decelerator for full-automatic solar energy single crystal furnace

A solar energy and single crystal furnace technology, applied in mechanical equipment, transmission devices, transmission device parts, etc., can solve the problems of inability to use solar energy single crystal furnaces, inability to dissipate heat, poor sealing performance of reducers, etc., and achieve dust-proof effect. Good, simple structure, to ensure the effect of heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

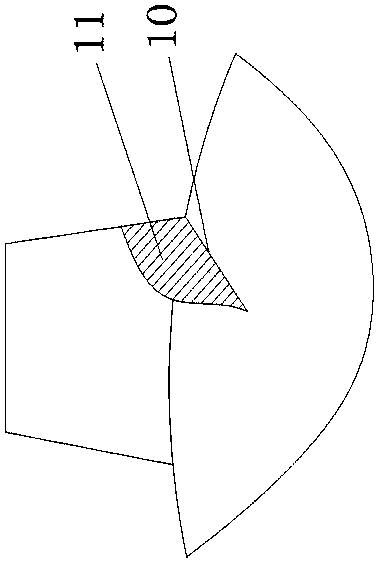

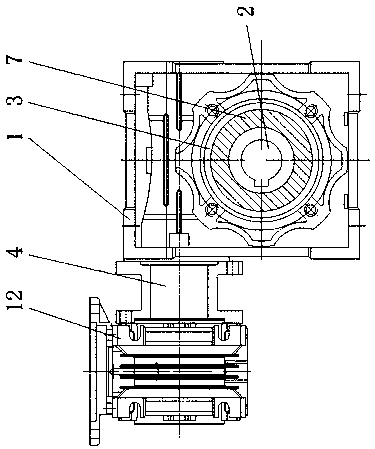

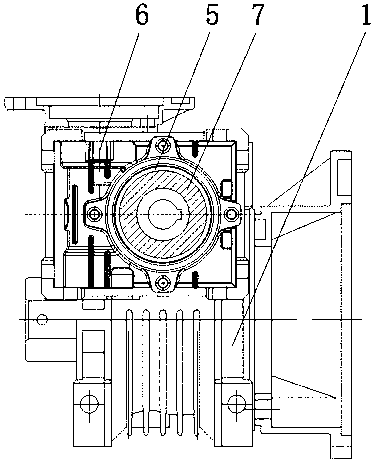

[0015] Embodiment: the special speed reducer of the fully automatic solar single crystal furnace of this example, such as figure 1 , figure 2 , including the main box body 1, the main box body is provided with an input shaft 2, the input shaft is connected with a first-level worm gear 3, the first-level worm gear is connected with a second-level worm gear 5 through a worm 4, and the second-level worm gear is arranged in the auxiliary box body 12, the second-level worm gear The first-stage worm wheel is connected to the output shaft 6, and the outer ends of the first-stage worm wheel and the second-stage worm wheel are all provided with seals 7. A cooling block 8 is embedded on the inner wall of the main box, and a plurality of cooling lips 9 are provided at the inner end of the cooling block. The tooth root of the first-stage worm wheel is provided with a reinforcement groove 10, and a reinforcement alloy block 11 is embedded in the reinforcement groove. The input shaft and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com