Full-automatic cutting and filling injecting machine for sandwiches

A fully automatic, sandwich technology, applied in baking, dough handling, food science, etc., can solve problems such as low degree of automation, difficulty in achieving full automation, and large movement resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

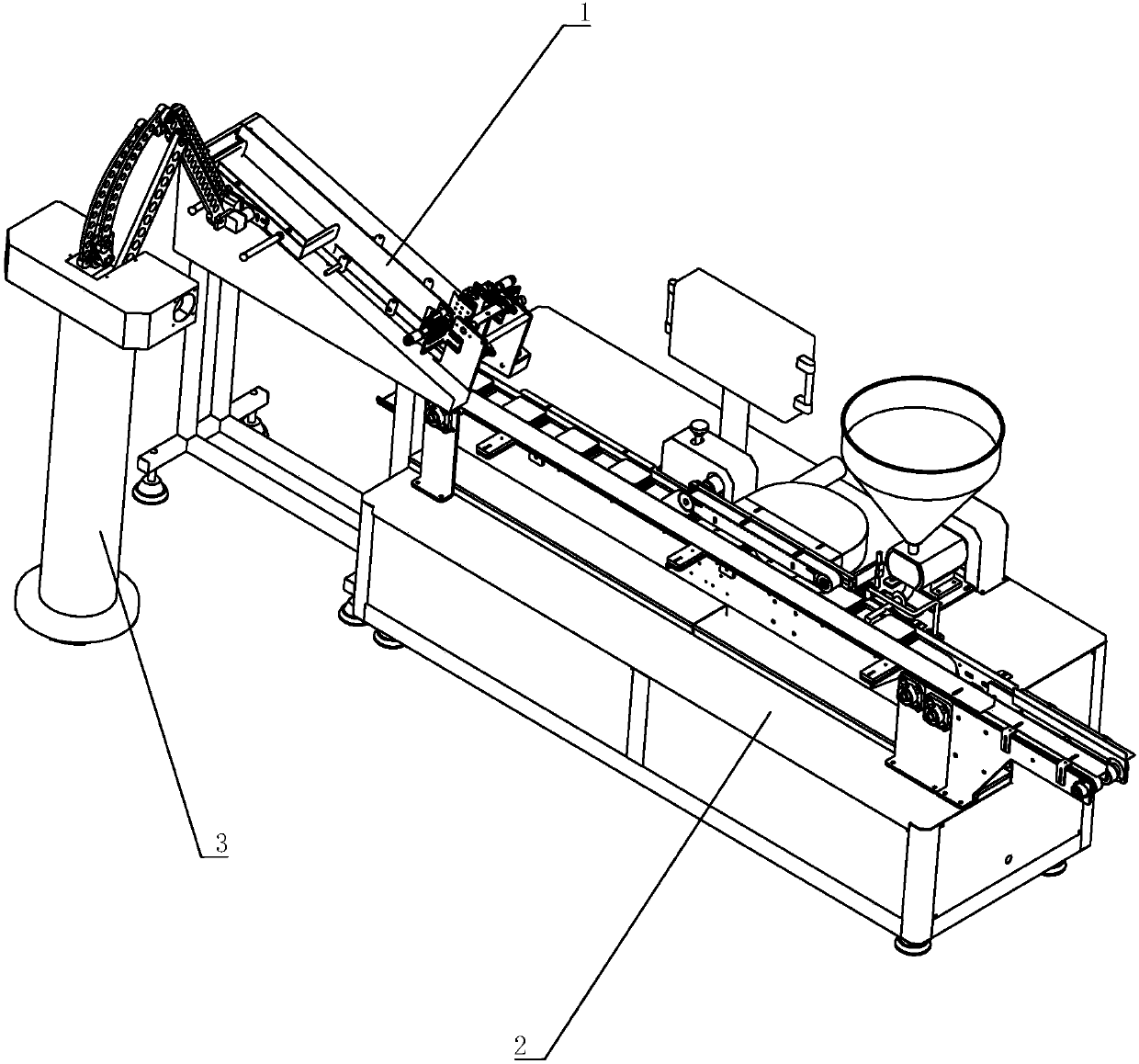

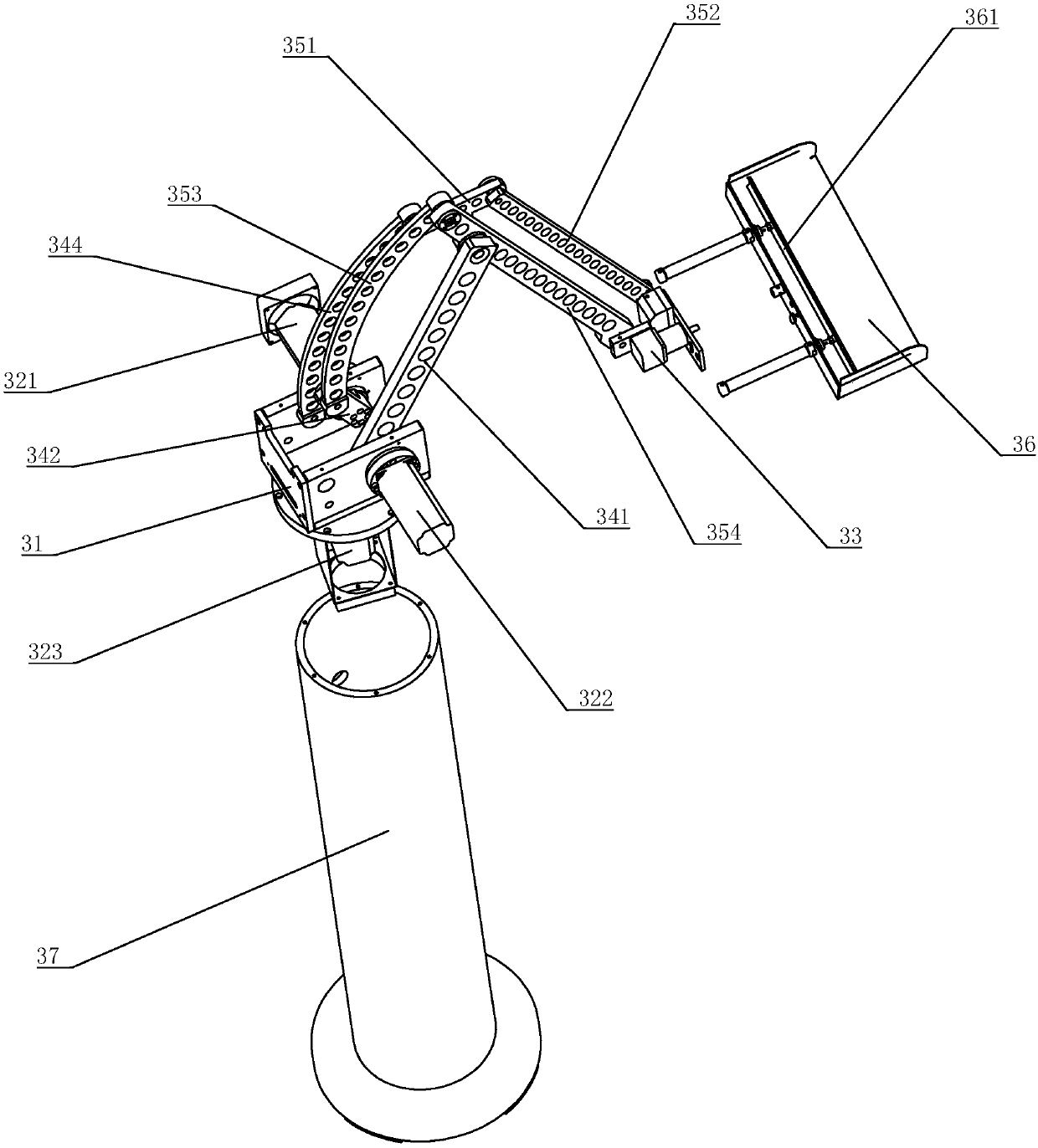

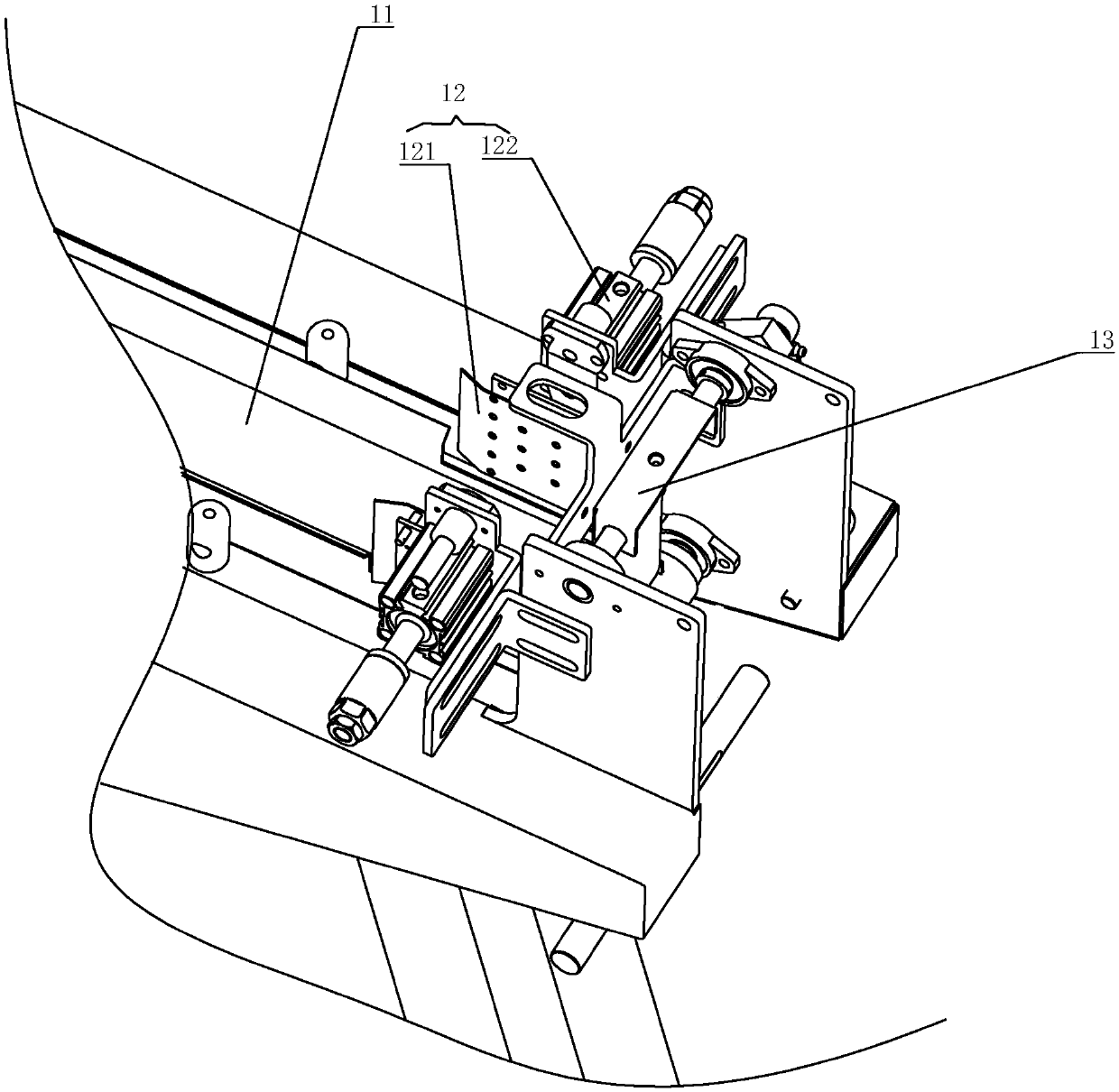

[0023] refer to Figure 1 to Figure 4 , a fully automatic sandwich filling machine of the present invention, comprising a manipulator device 3 arranged at the front for carrying and feeding materials, a bread feeder 1 connected in sequence, and a cutting and filling mechanism 2;

[0024] The mechanical handling hand device 3 includes an organic platform 31, a first driver 321 and a second driver 322 are respectively installed on the front and rear sides of the platform 31, and the output shafts of the first driver 321 and the second driver 322 are parallel to each other and They are respectively connected with the same link mechanism, and one end of the link mechanism is connected with an actuator 33, and the actuator 33 is provided with a hopper 36, and the inside of the hopper 36 is slidably connected by a third cylinder arranged on both sides of the actuator 33. There is a push plate 361, and the mechanical handling hand device 3 also includes a mounting column 37, a third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com