Patents

Literature

36results about How to "Automate the transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

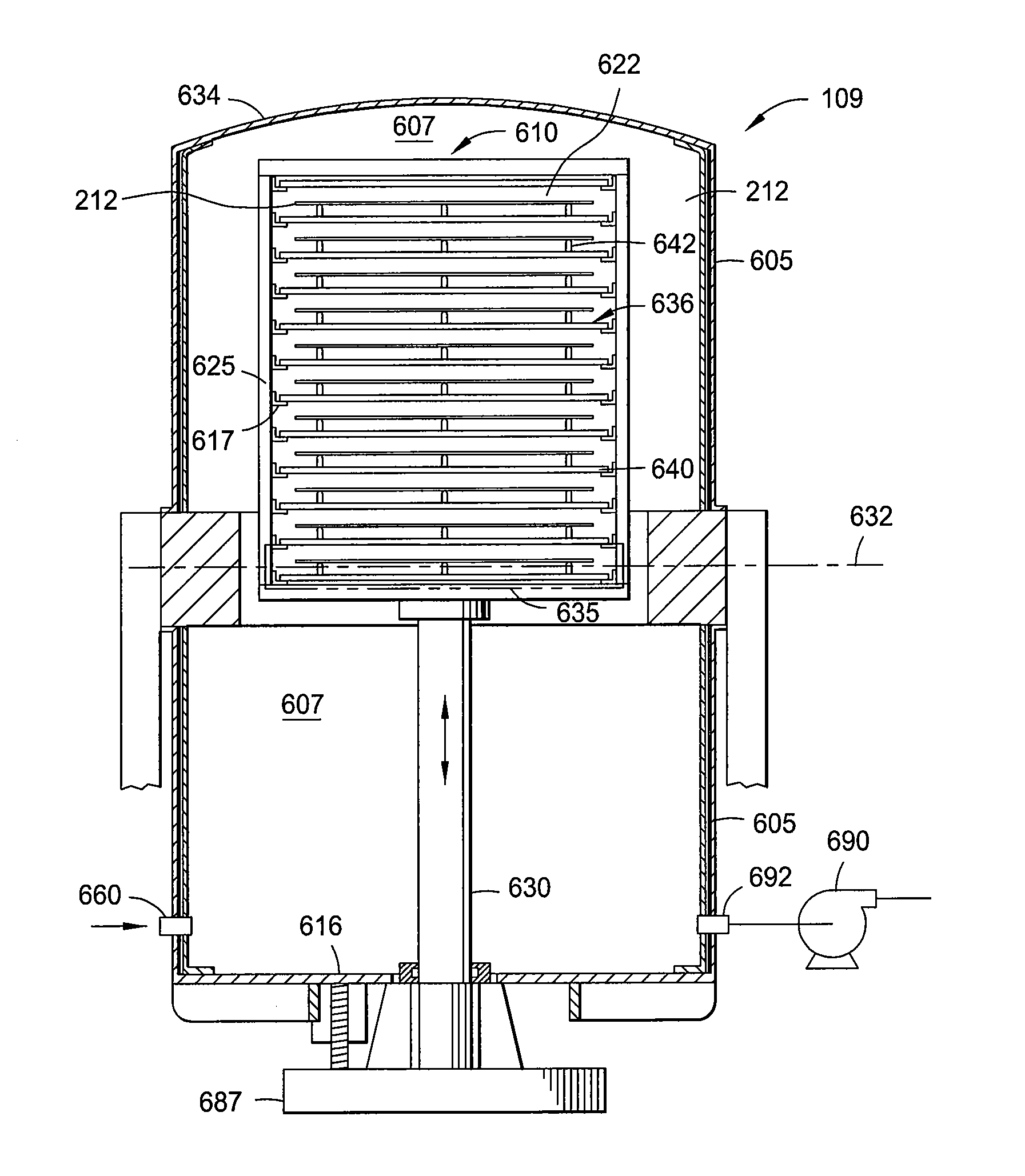

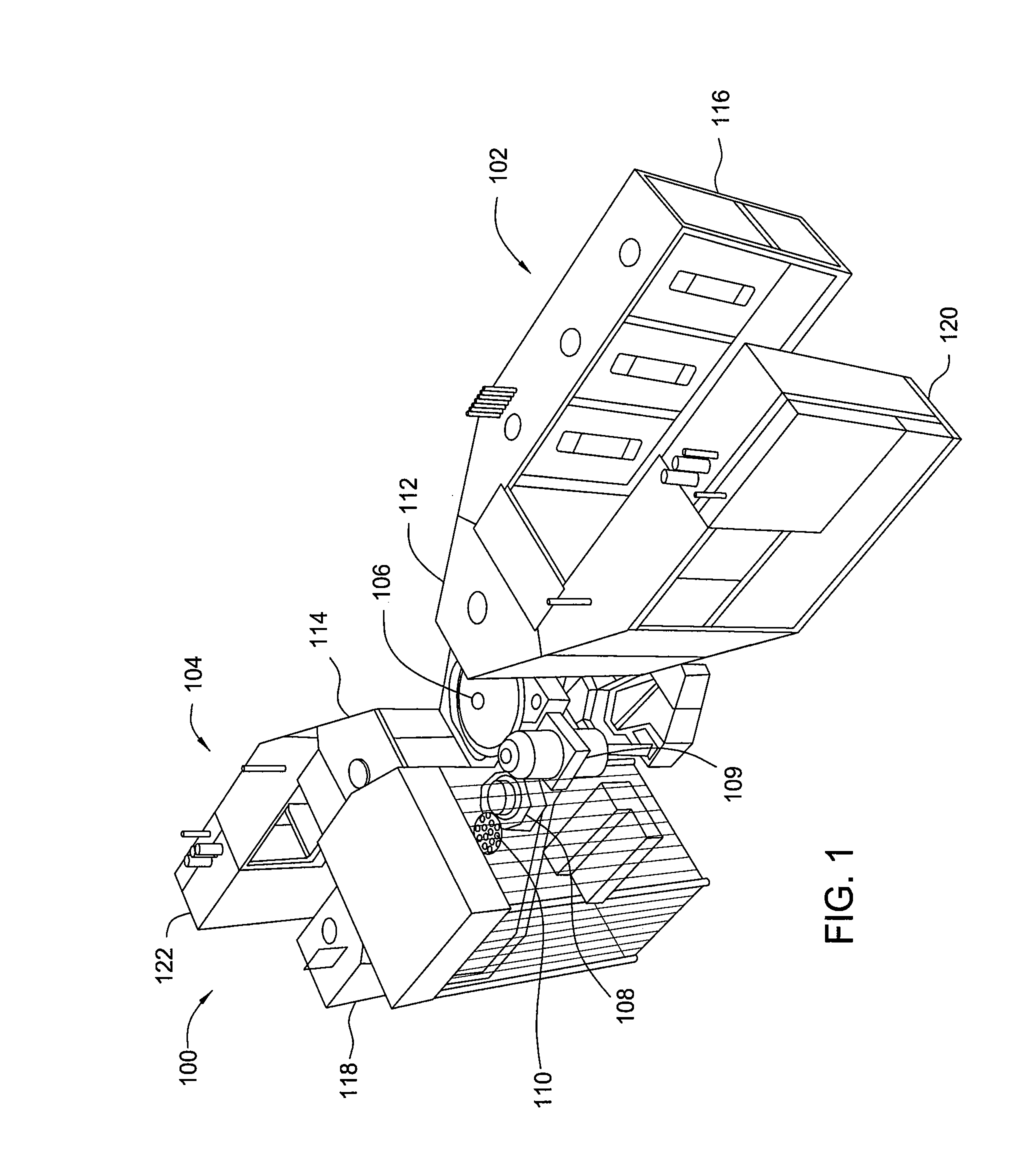

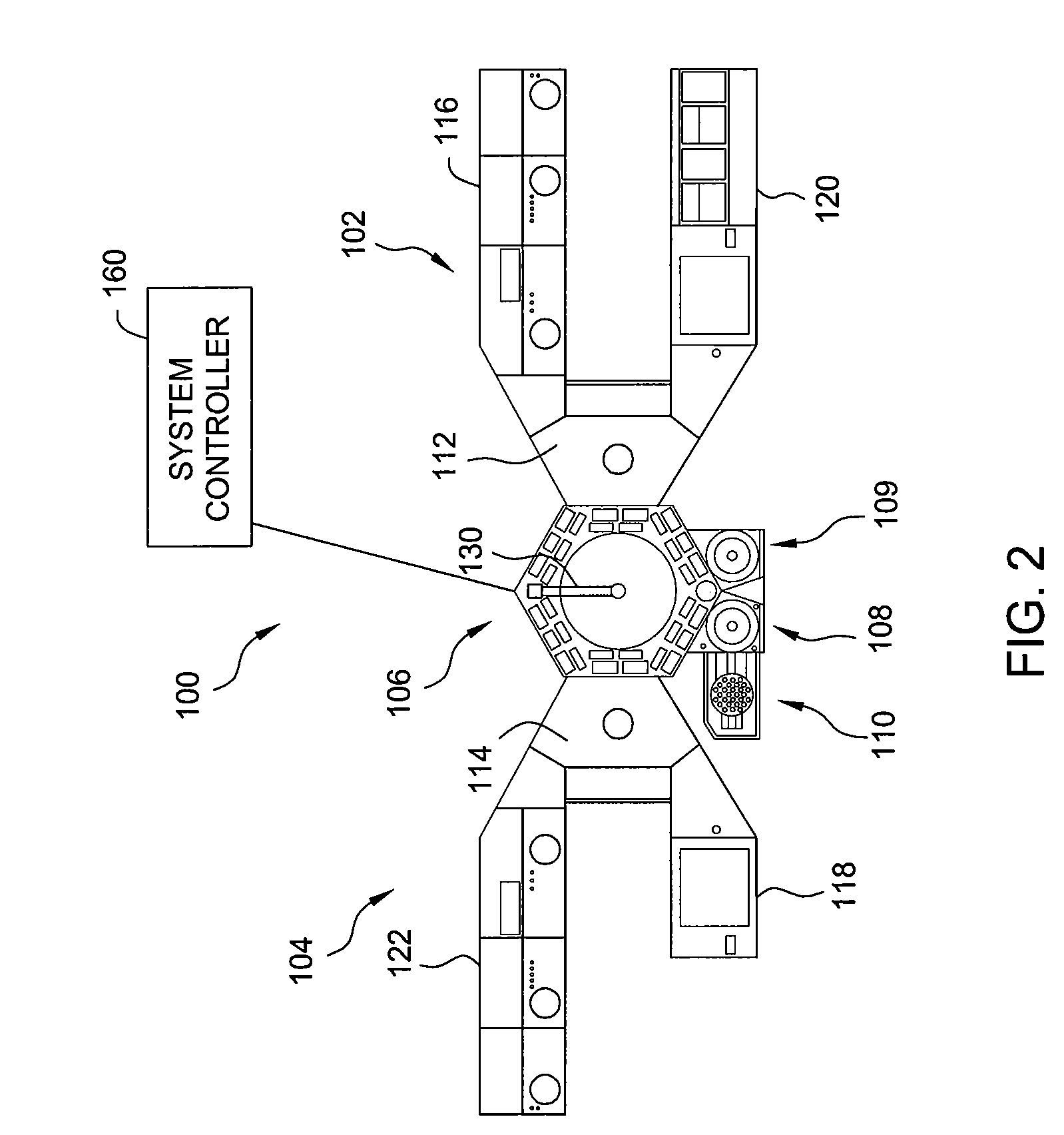

Processing system for fabricating compound nitride semiconductor devices

InactiveUS20090194026A1Expands available process windowImprove system throughputAfter-treatment apparatusPolycrystalline material growthCompound structureEngineering

One embodiment of a processing system for fabricating compound nitride semiconductor devices comprises one or more processing chamber operable with form a compound nitride semiconductor layer on a substrate, a transfer chamber coupled with the processing chamber, a loadlock chamber coupled with the transfer chamber, and a load station coupled with the loadlock chamber, wherein the load station comprises a conveyor tray movable to convey a carrier plate loaded with one or more substrates into the loadlock chamber. Compared to a single chamber reactor, the multi-chamber processing system expands the potential complexity and variety of compound structures. Additionally, the system can achieve higher quality and yield by specialization of individual chambers for specific epitaxial growth processes. Throughput is increased by simultaneous processing in multiple chambers.

Owner:APPLIED MATERIALS INC

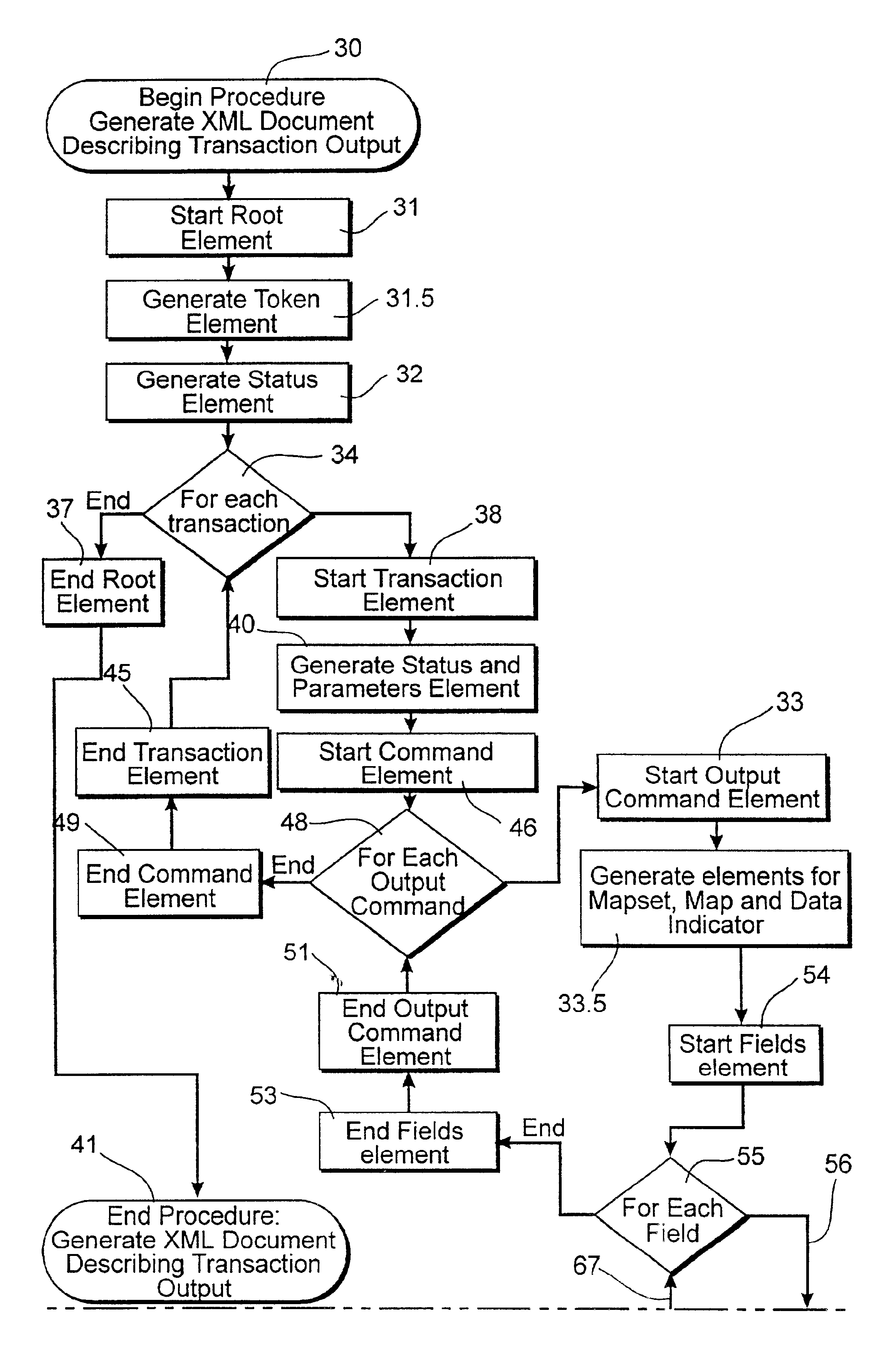

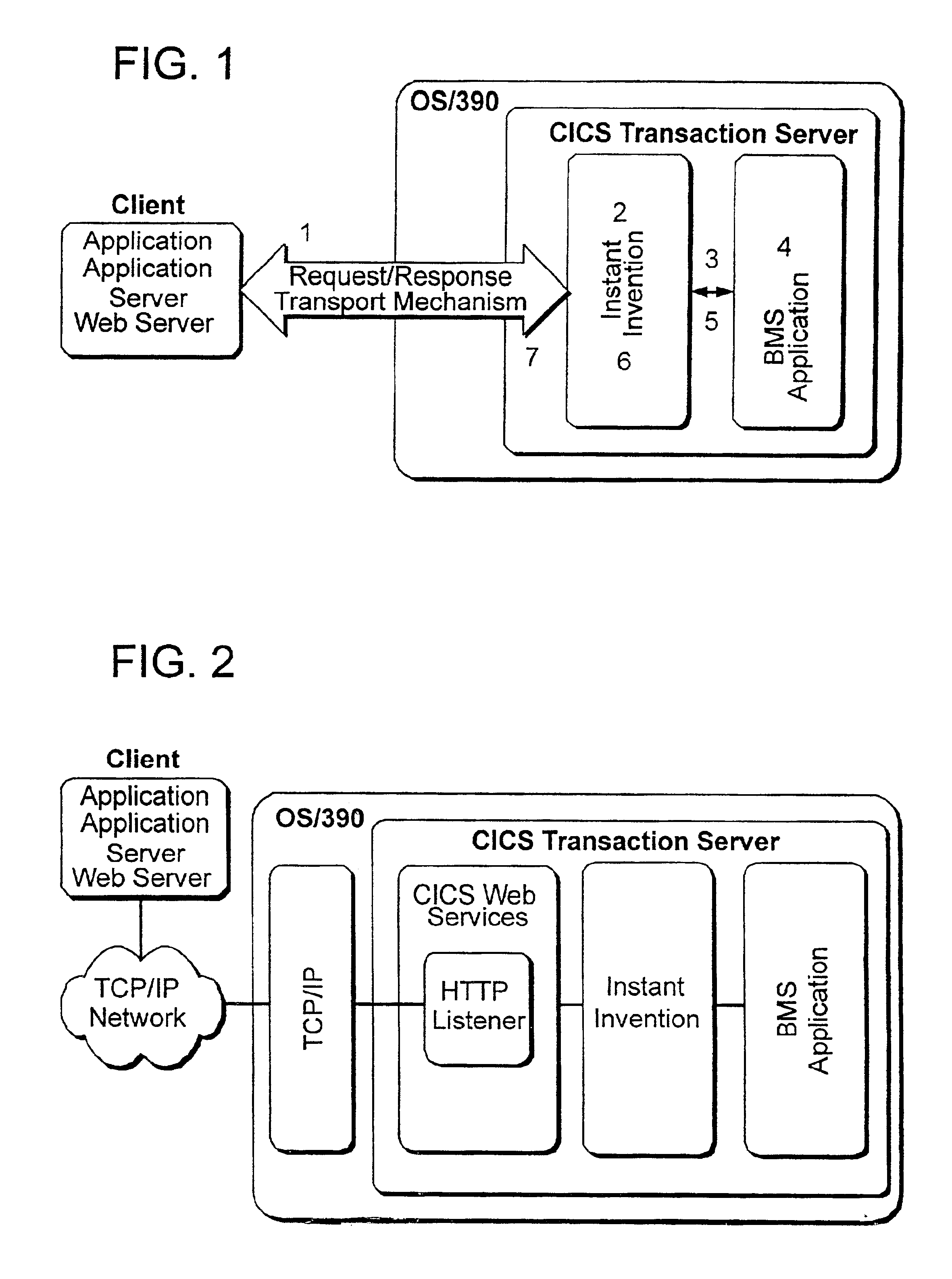

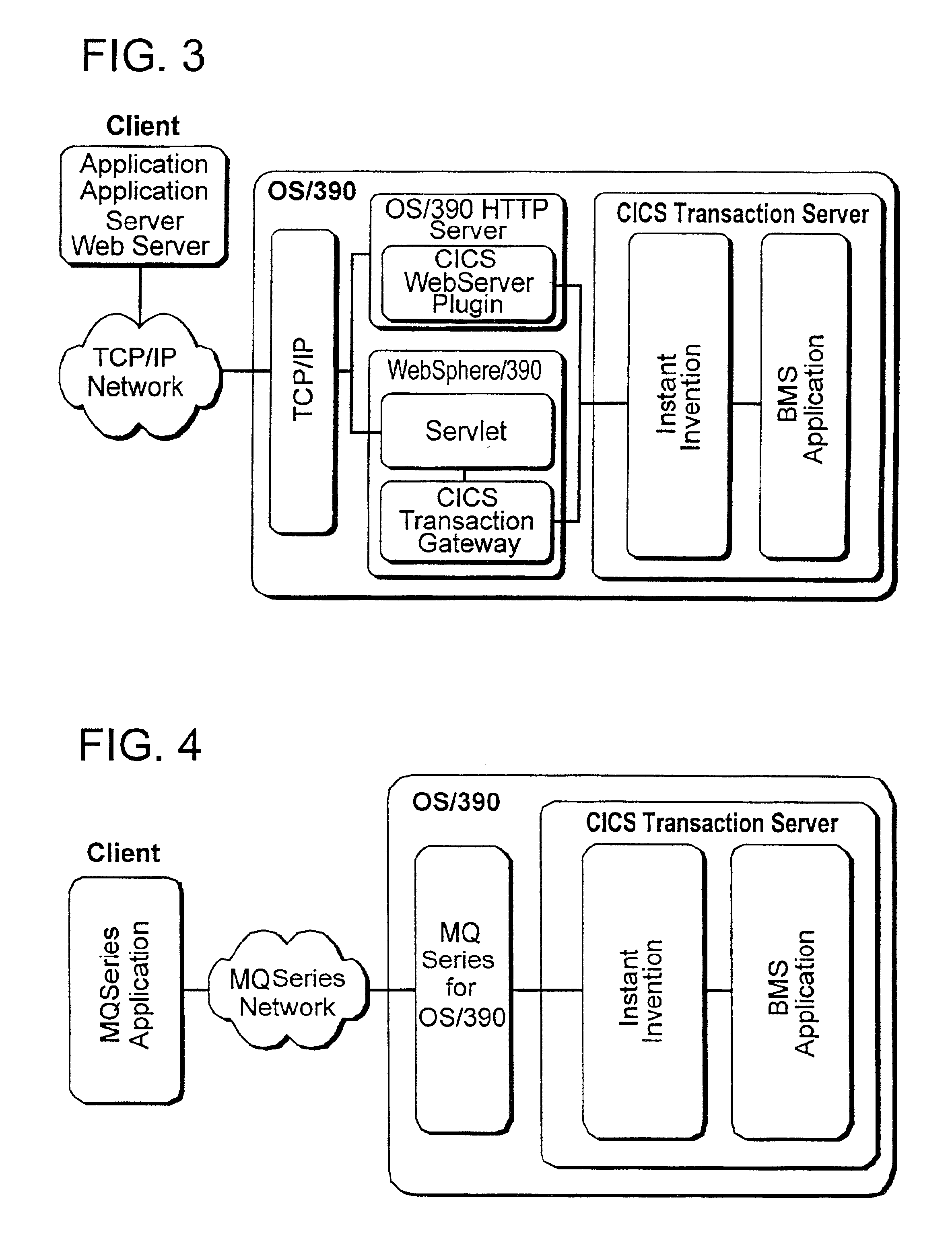

System, method and apparatus to allow communication between CICS and non-CICS software applications

ActiveUS6981257B2Facilitate transactionEasy to callMultiprogramming arrangementsSpecial data processing applicationsApplication softwareCICS

A system, method and apparatus to facilitate the invocation of existing CICS BMS transactions and deliver the executed transaction output to a requesting application as a standardized XML document. Building upon a facility which intercepts the flow of control between a user transaction and BMS, the instant invention replaces the use of terminal-oriented data streams with XML documents. In doing so, the instant invention eliminates the use of prior art techniques, such as “screen scraping”.

Owner:CA TECH INC

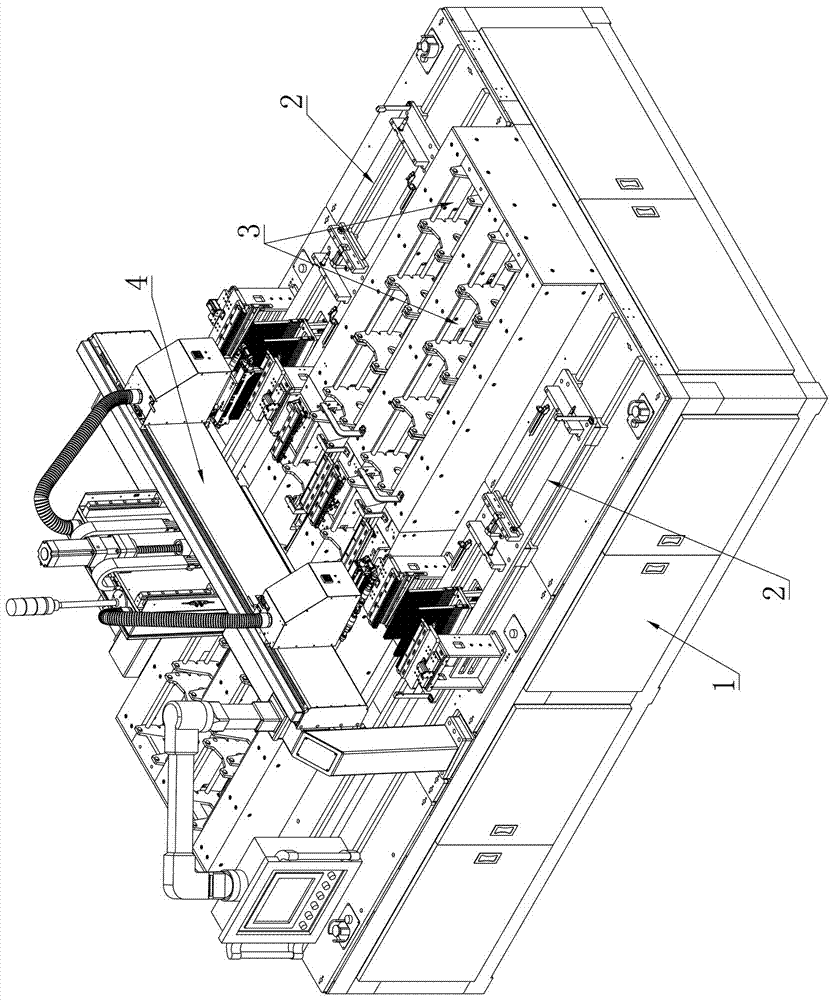

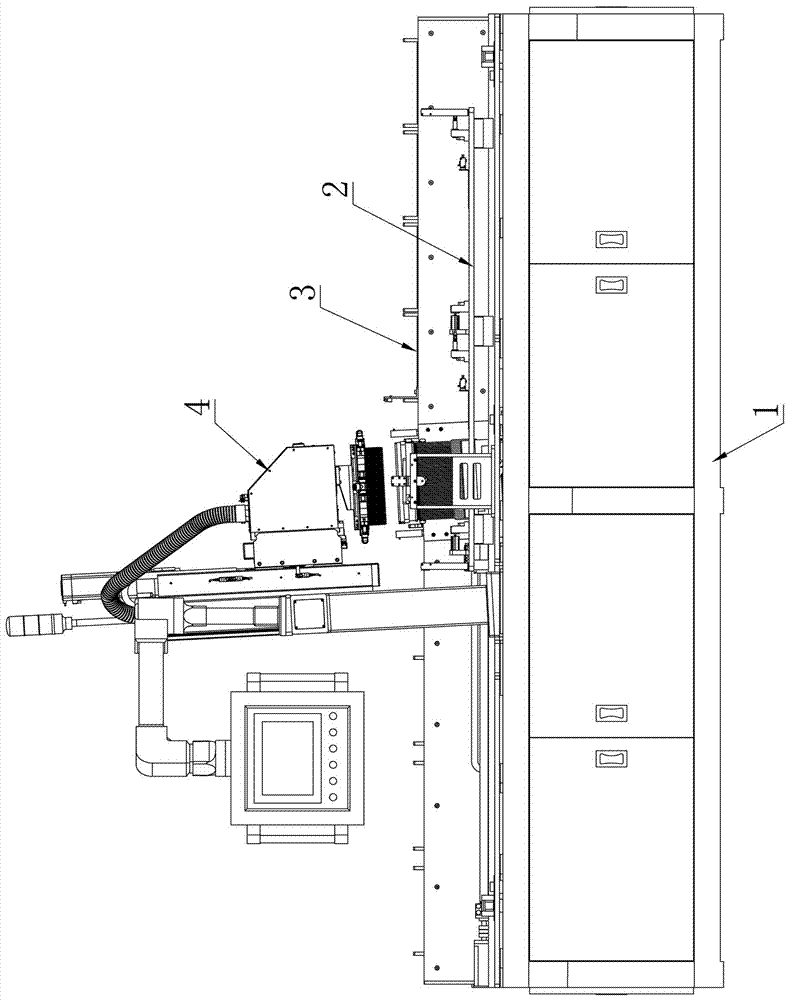

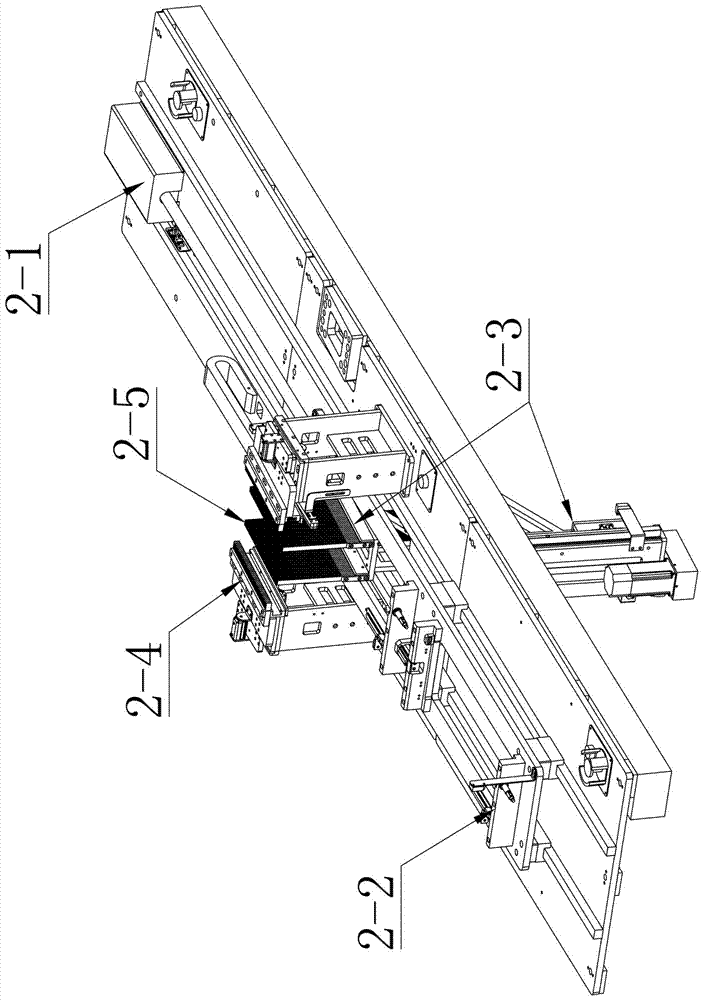

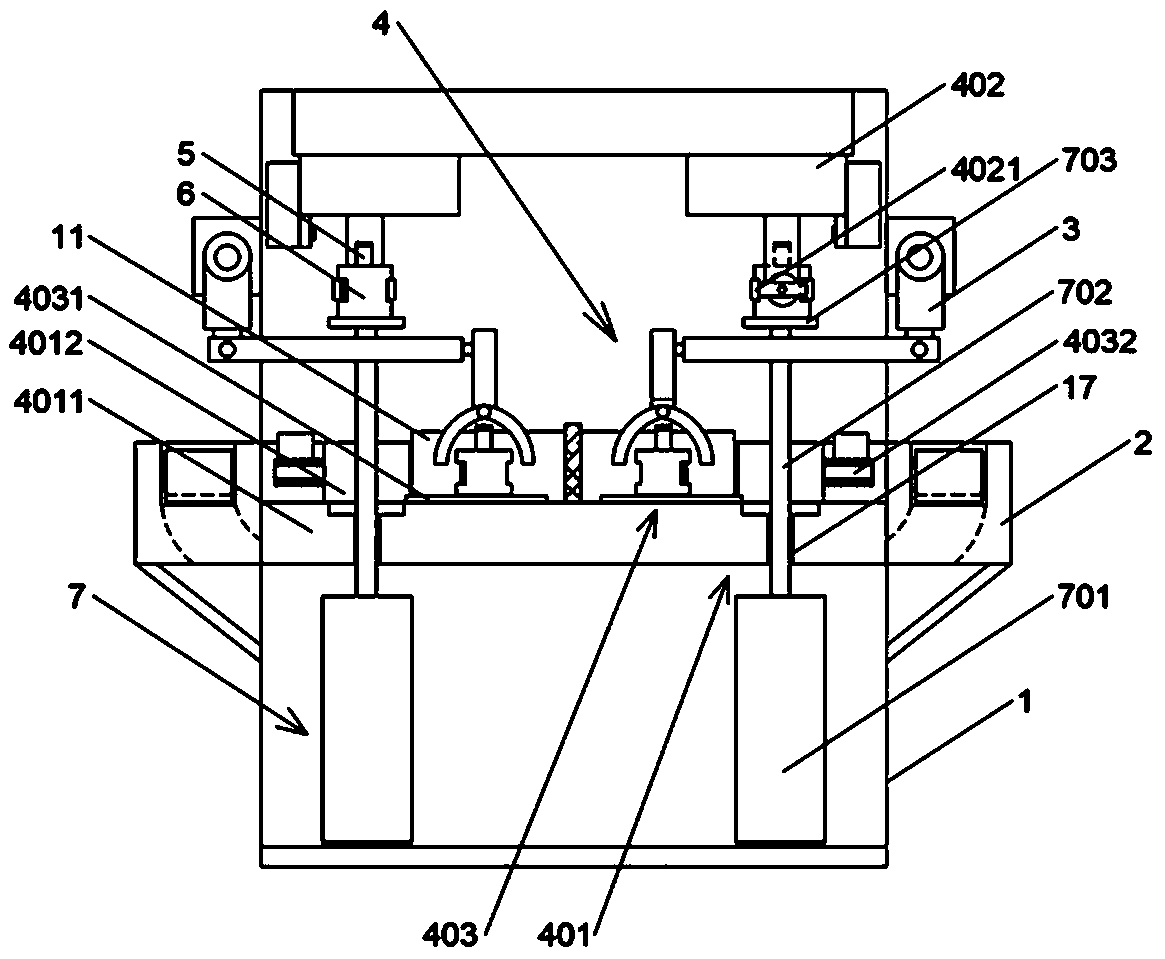

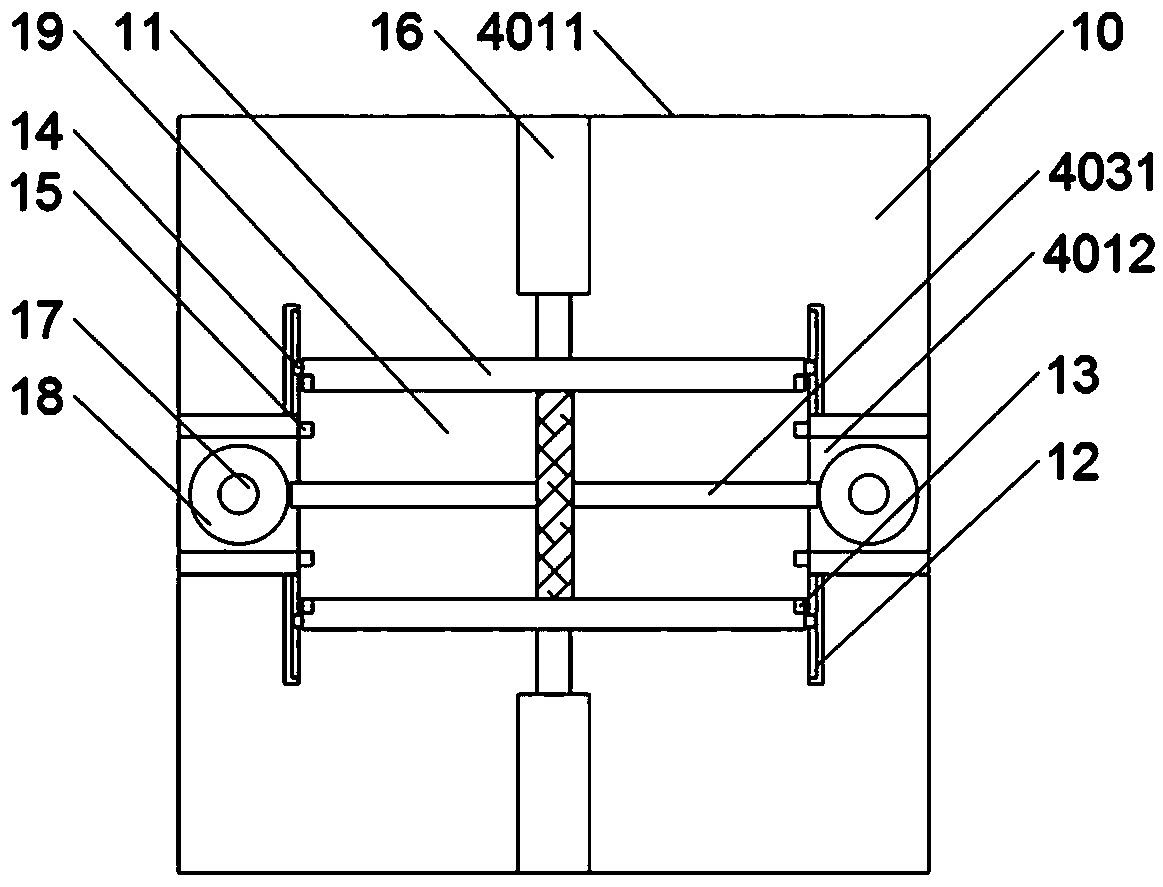

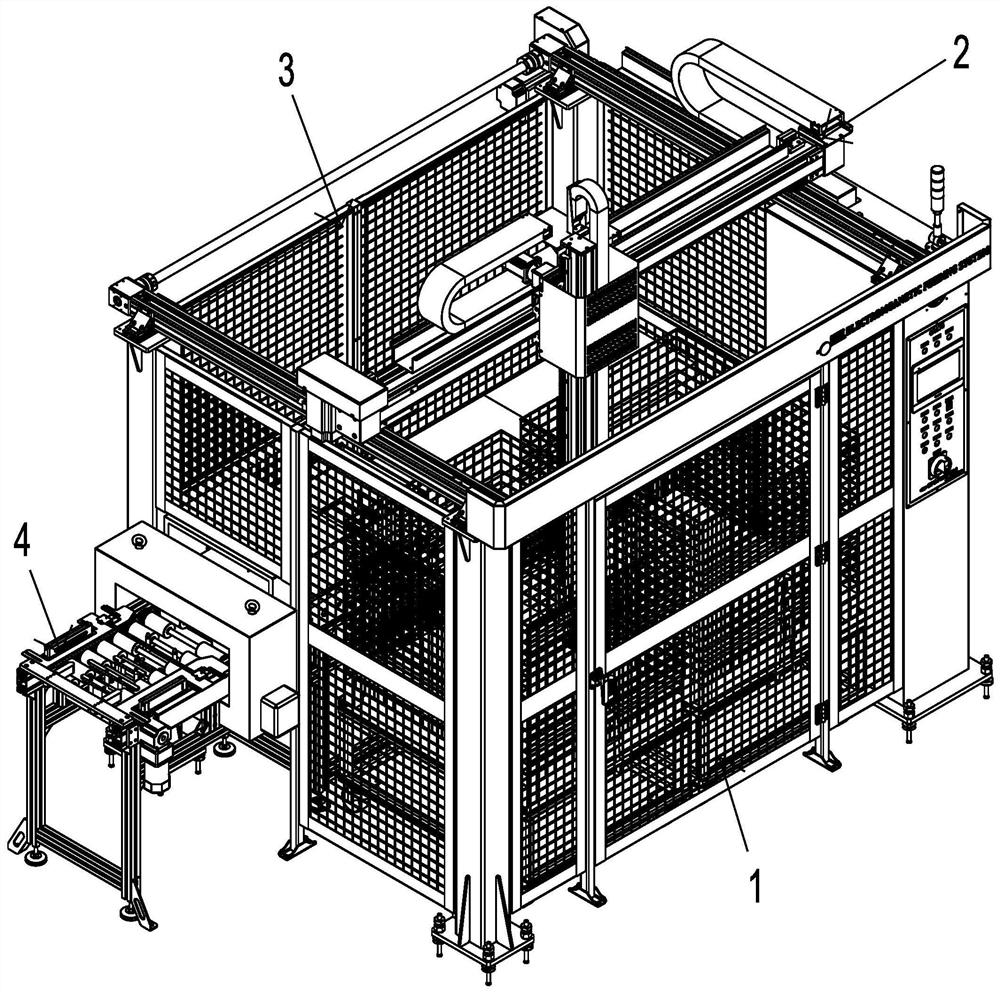

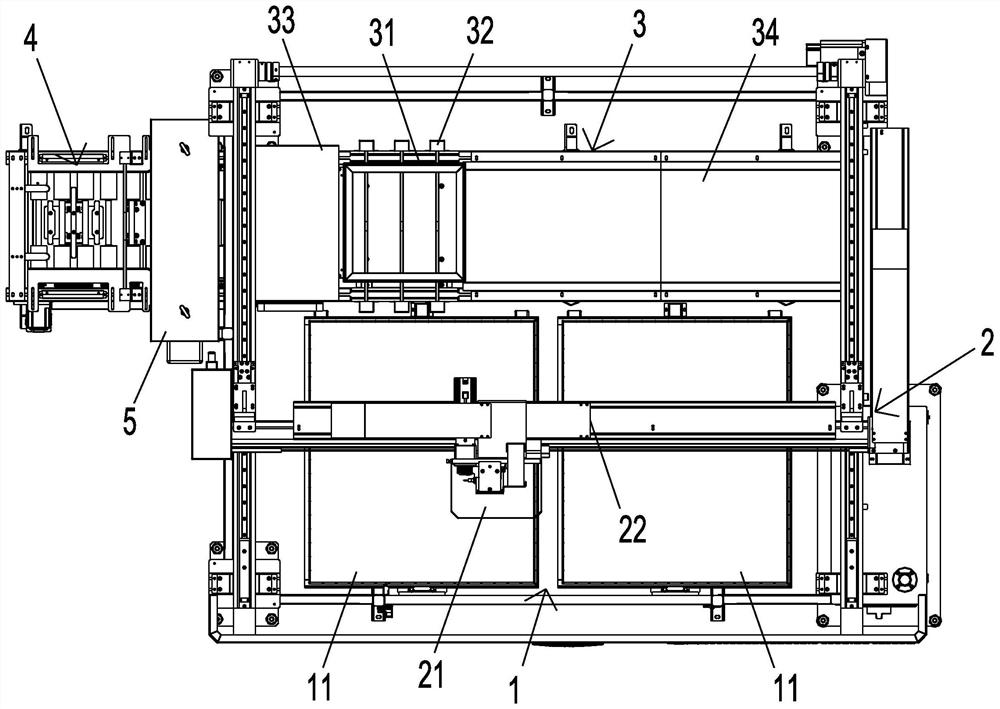

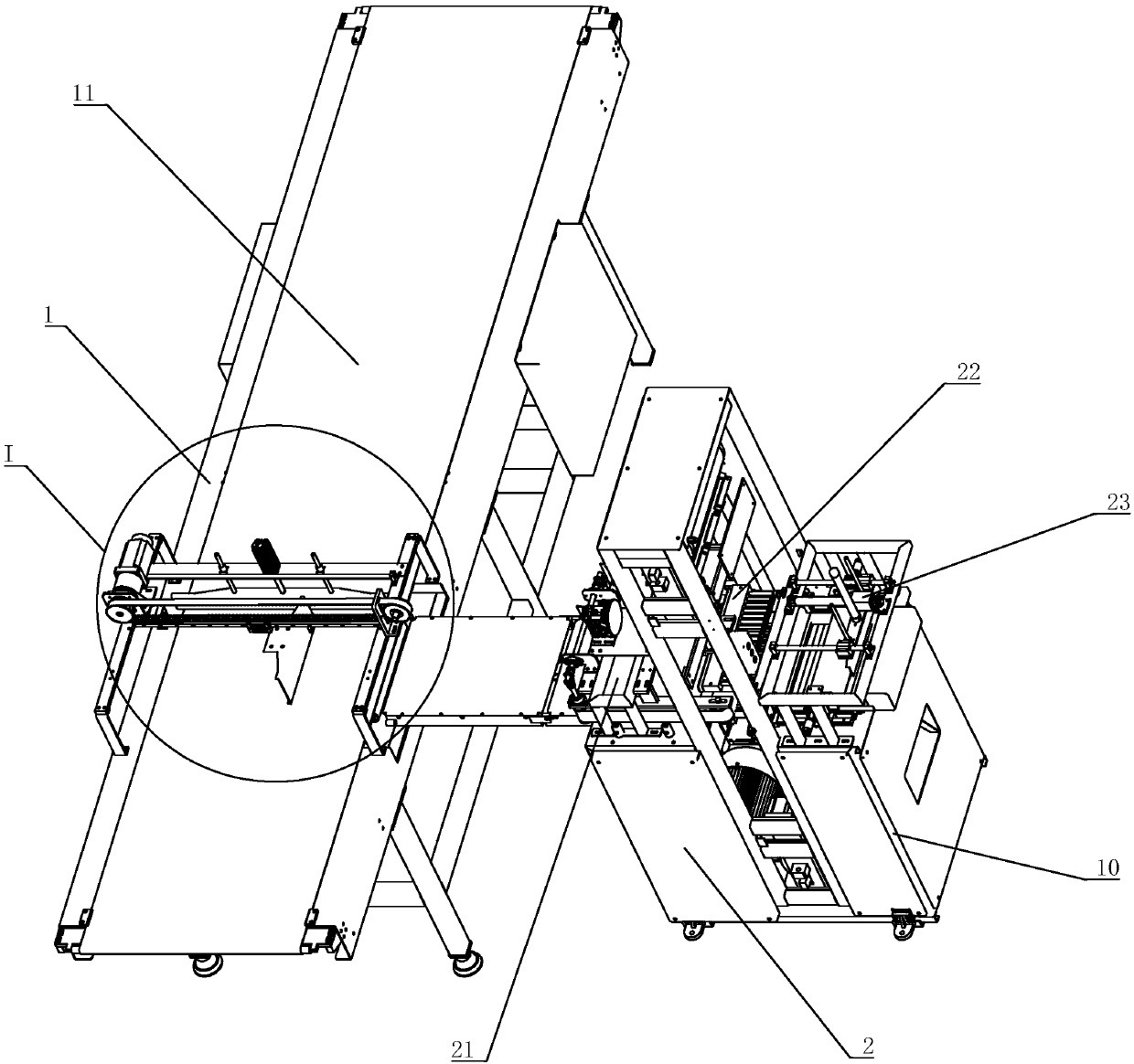

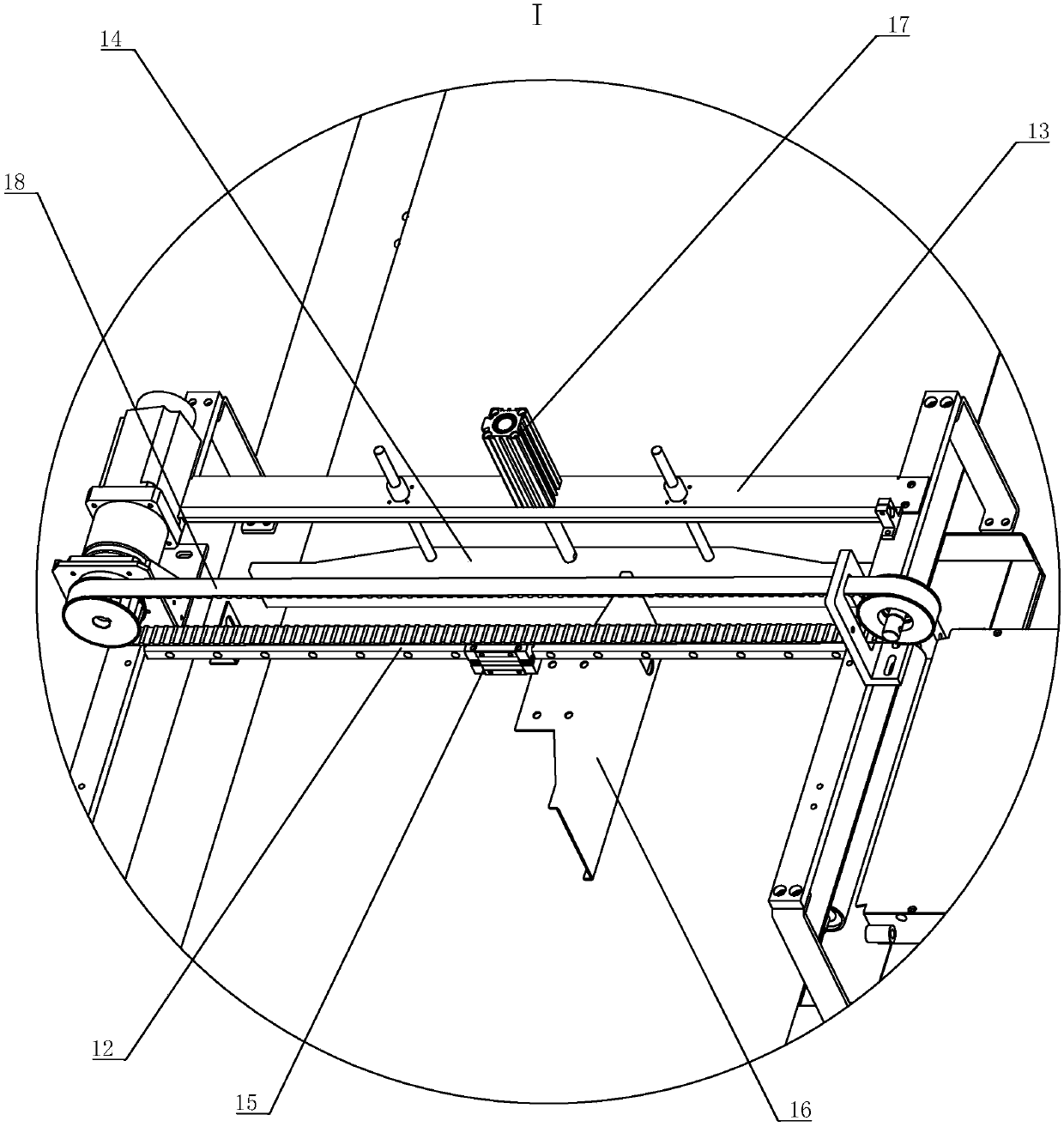

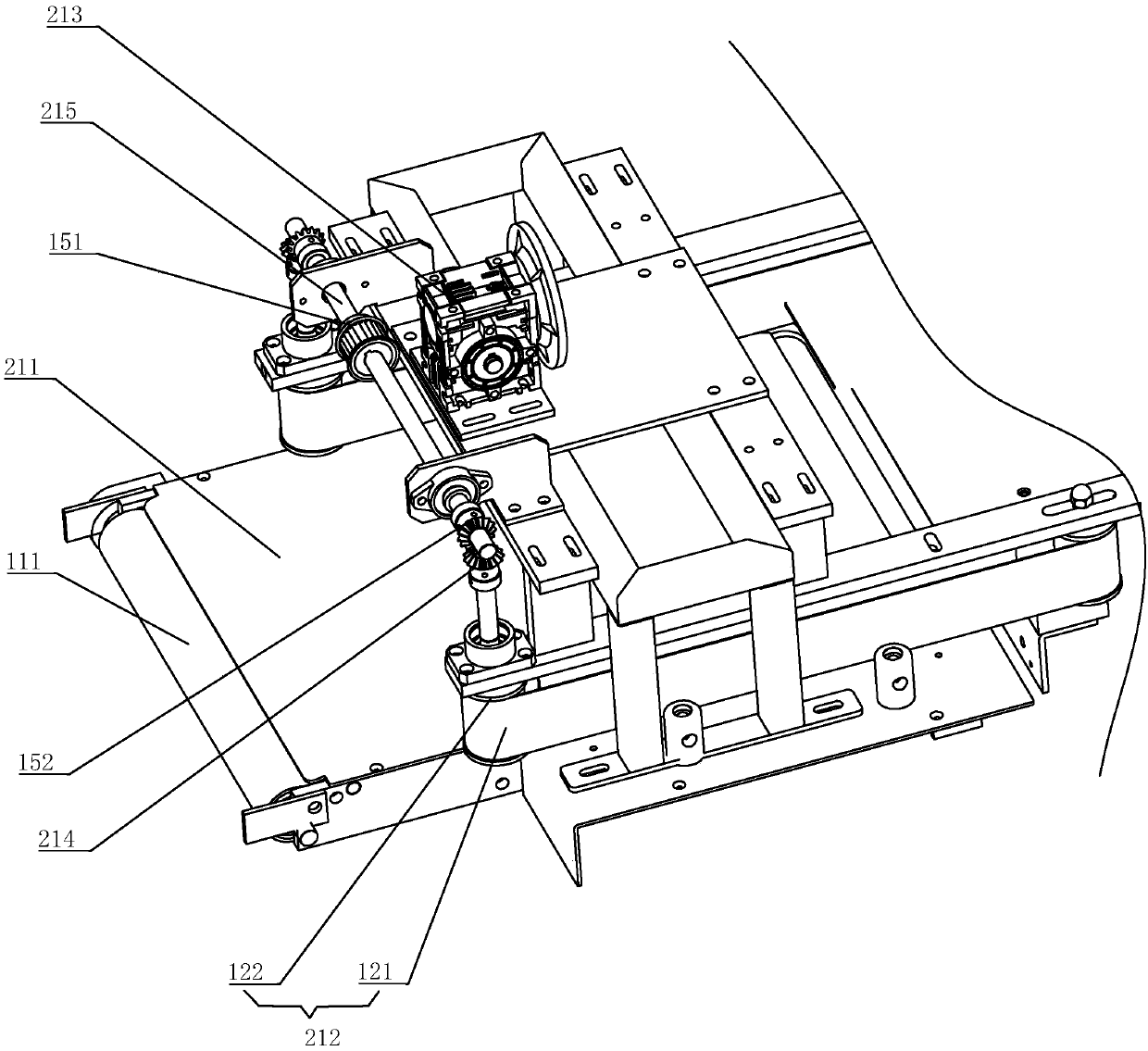

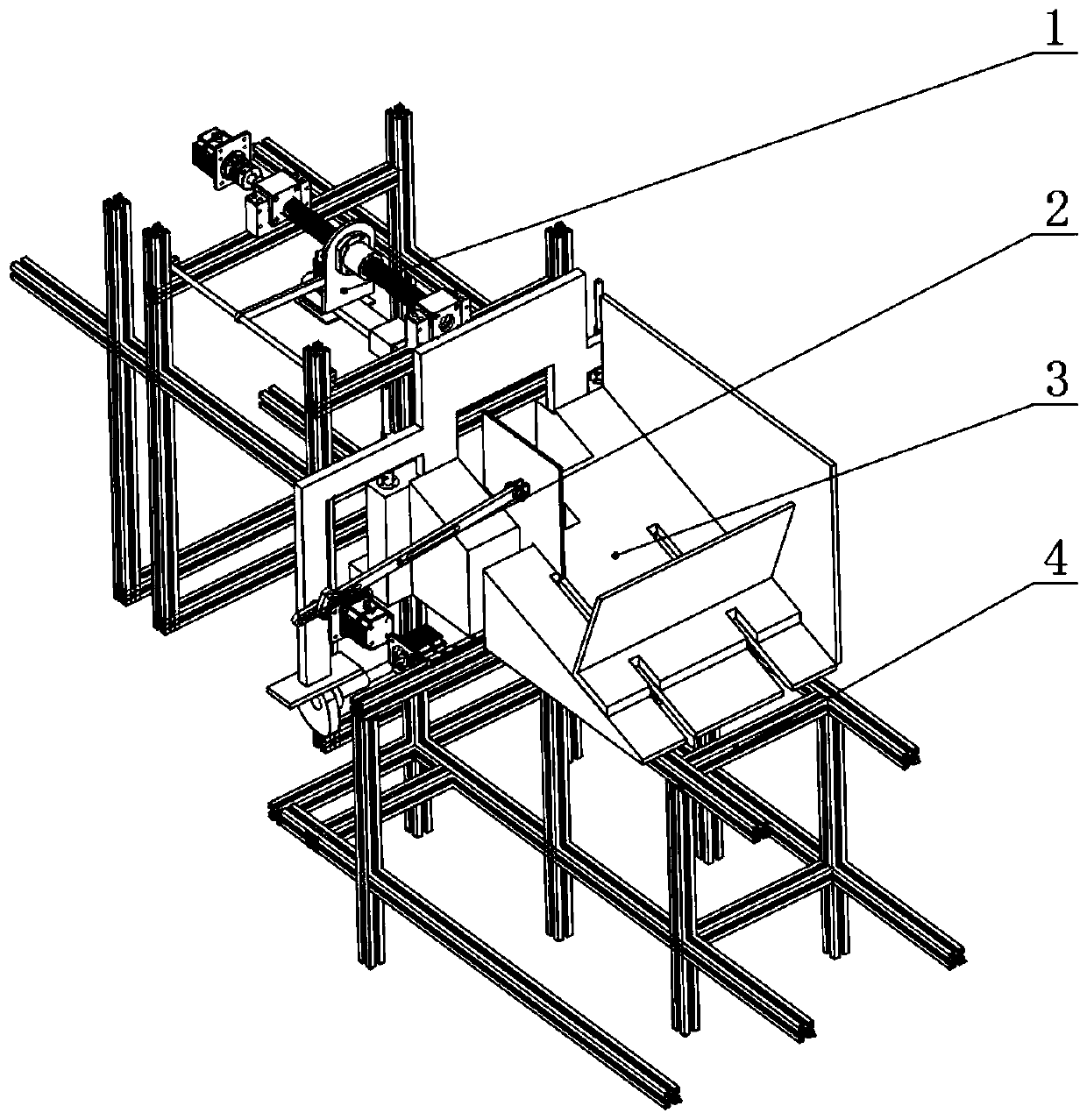

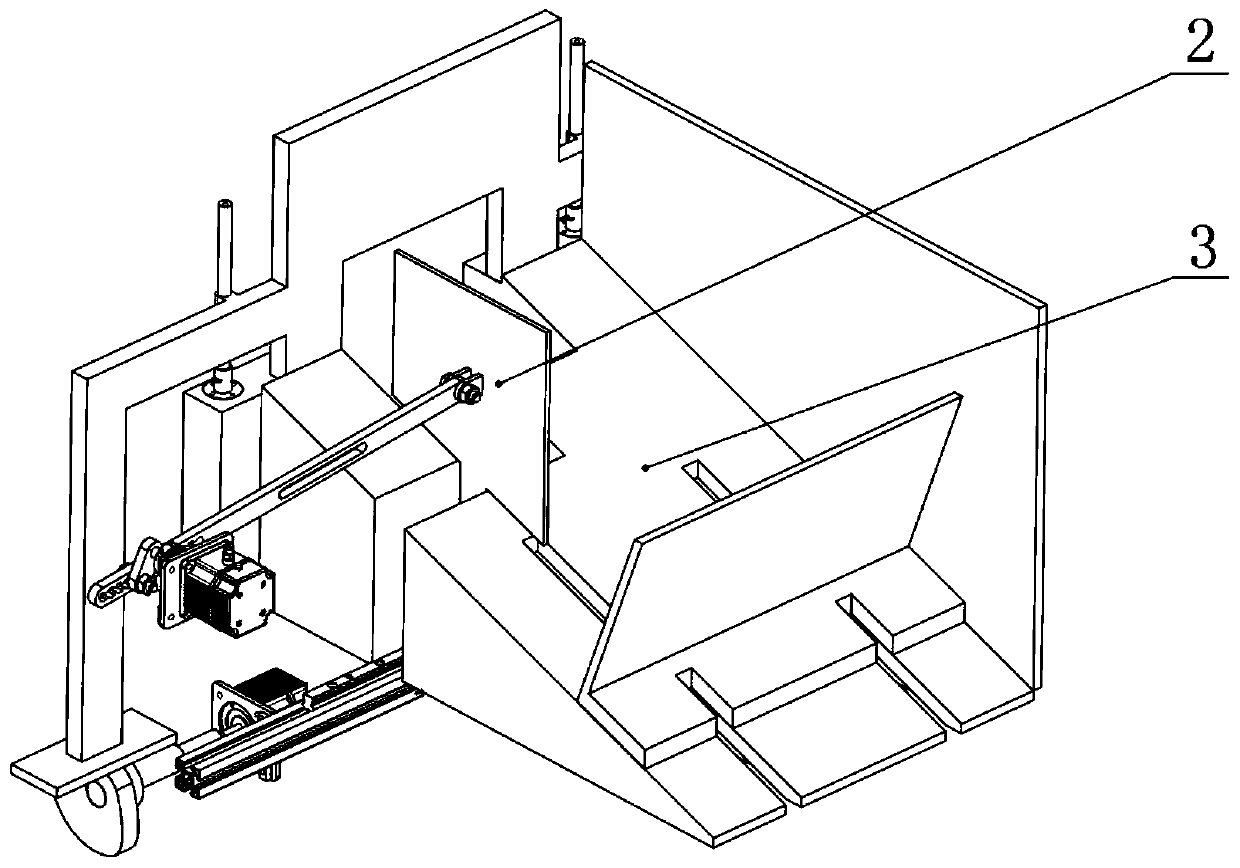

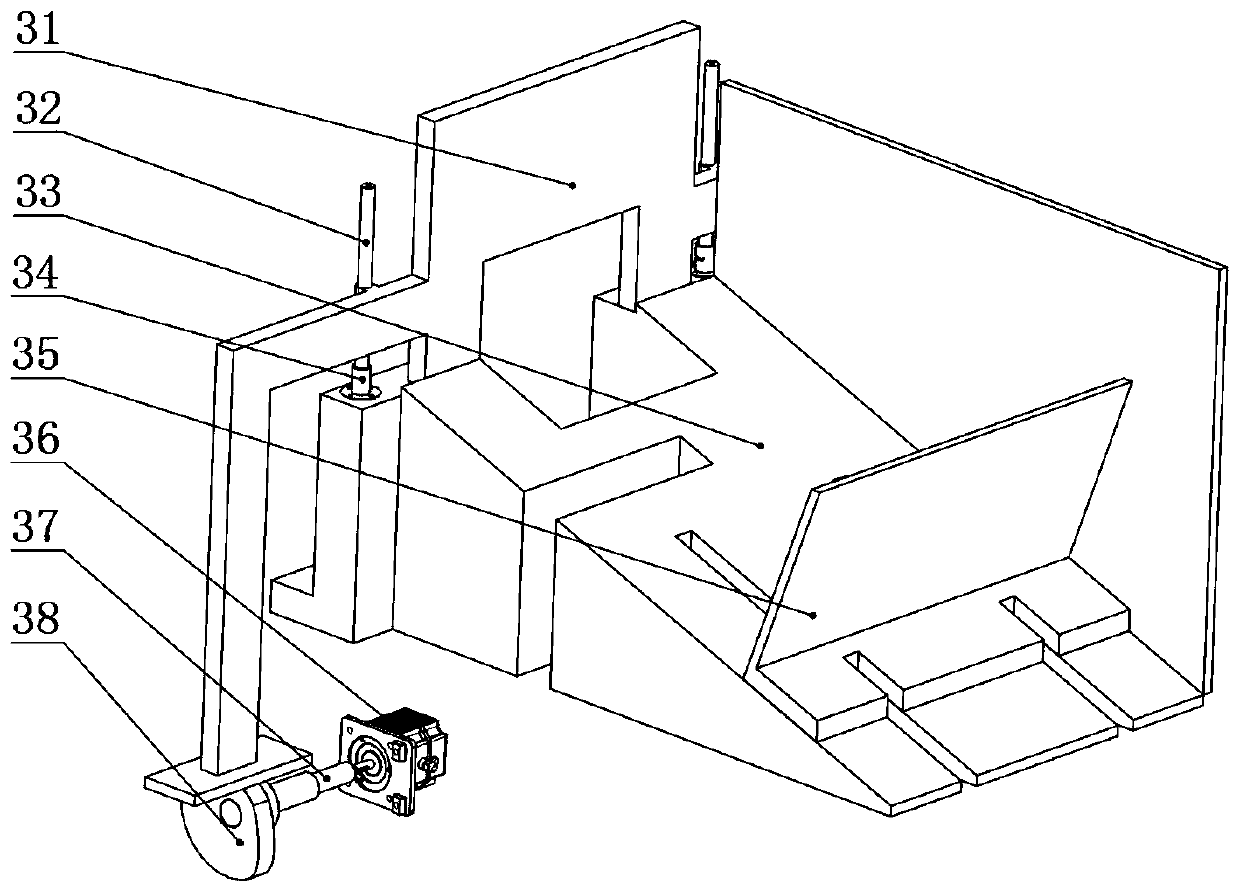

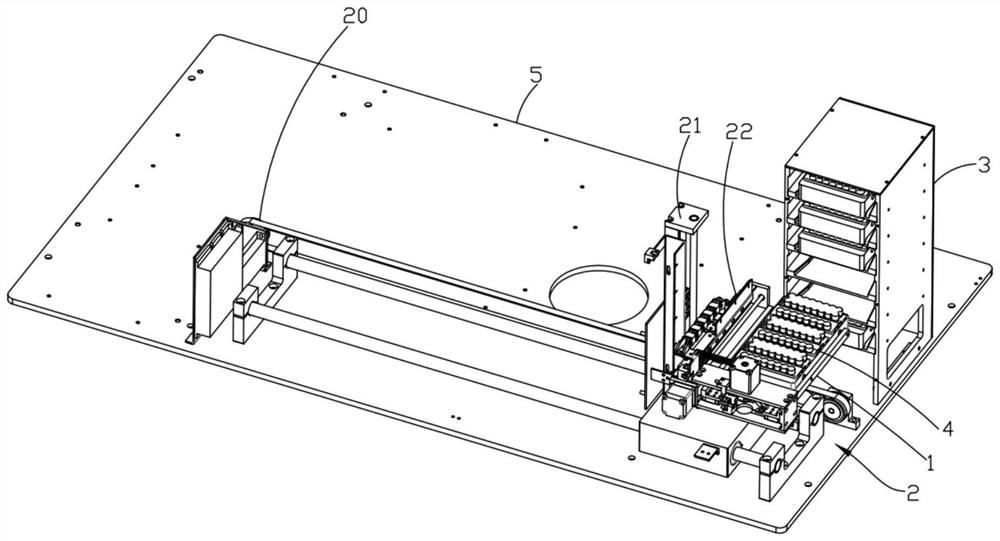

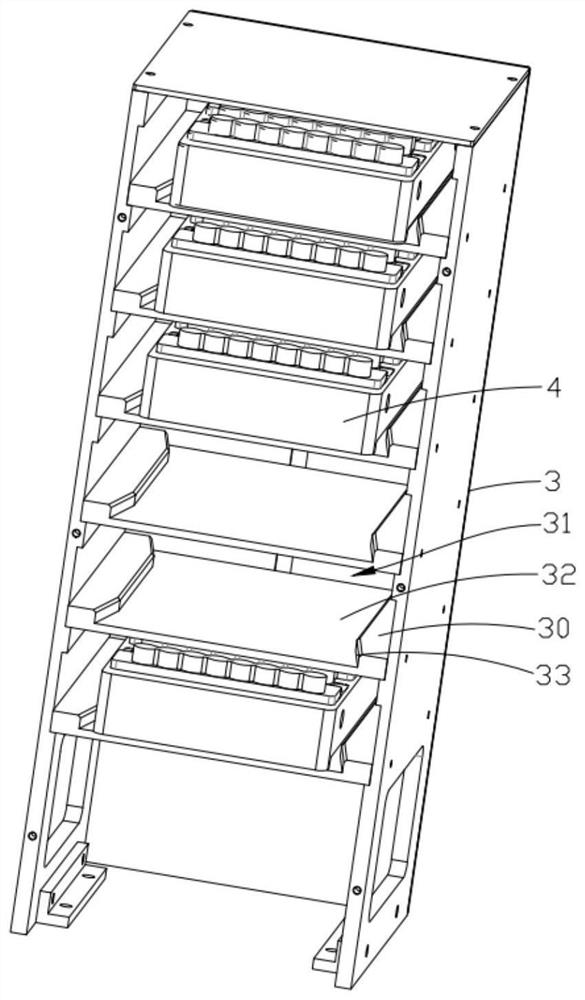

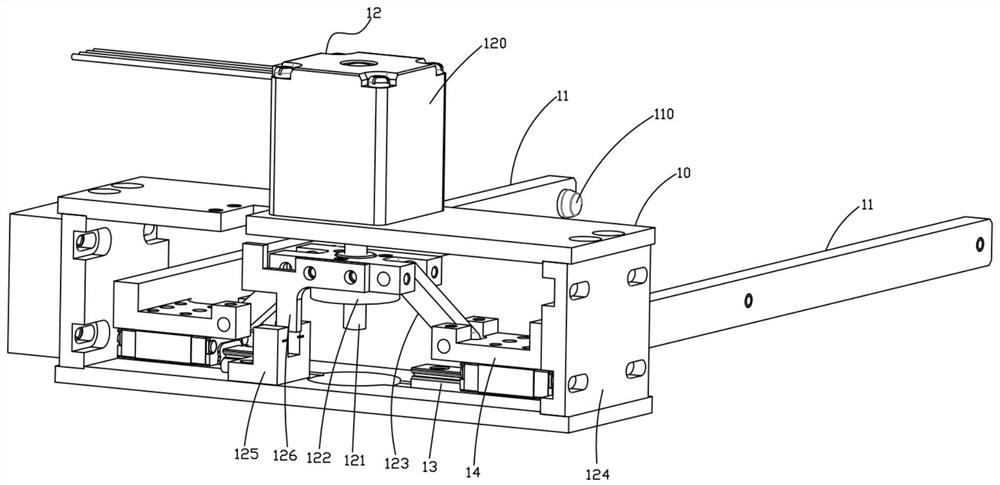

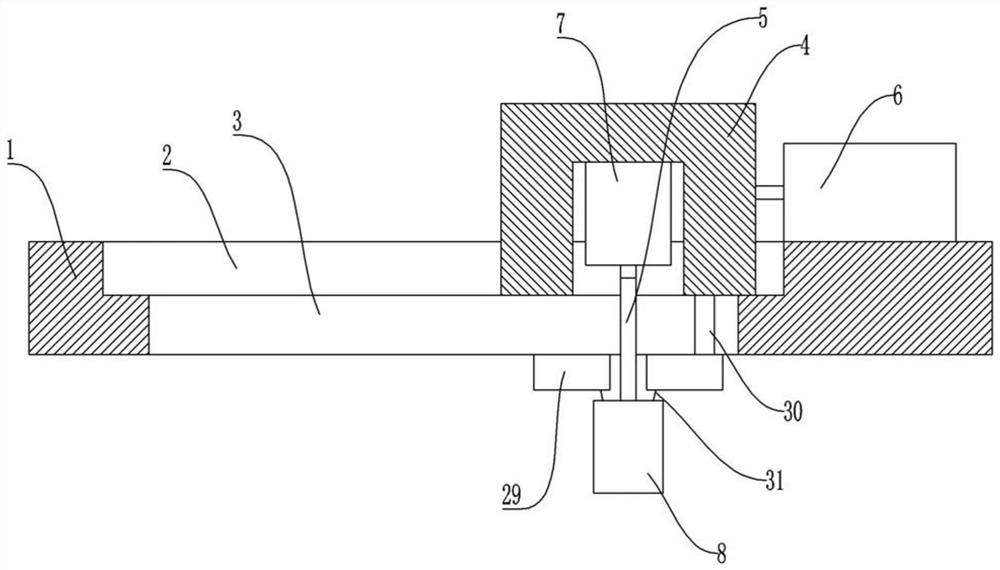

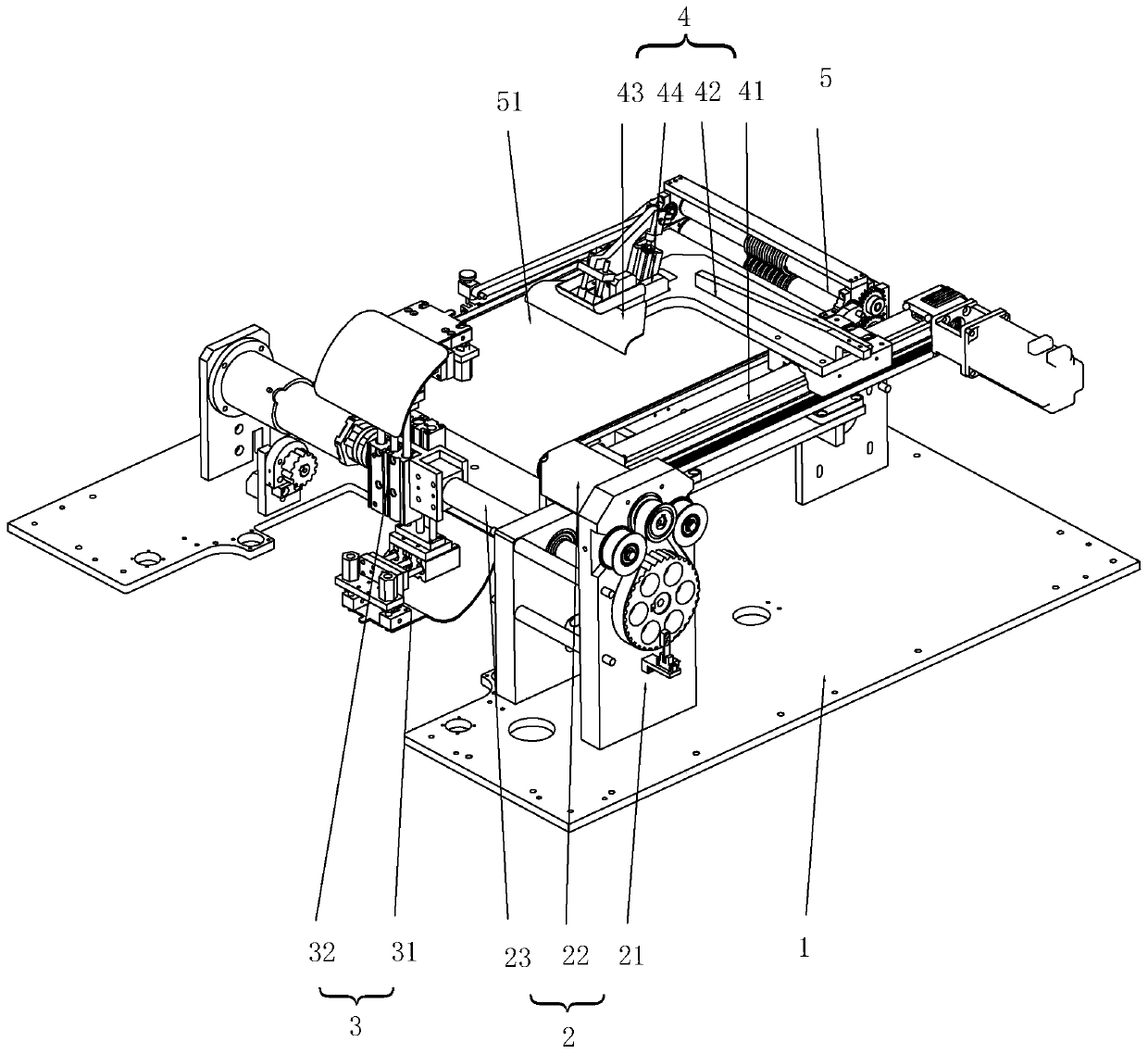

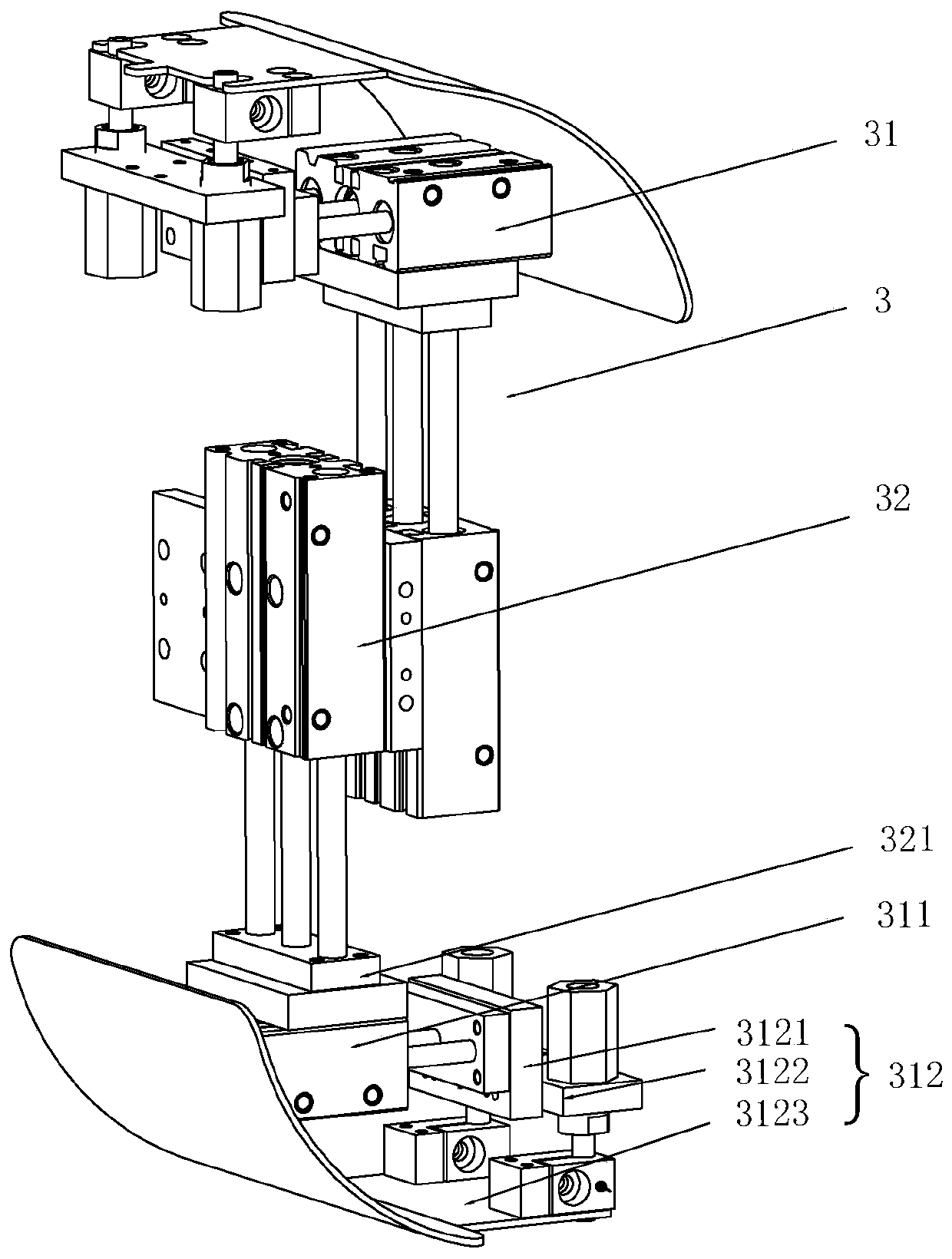

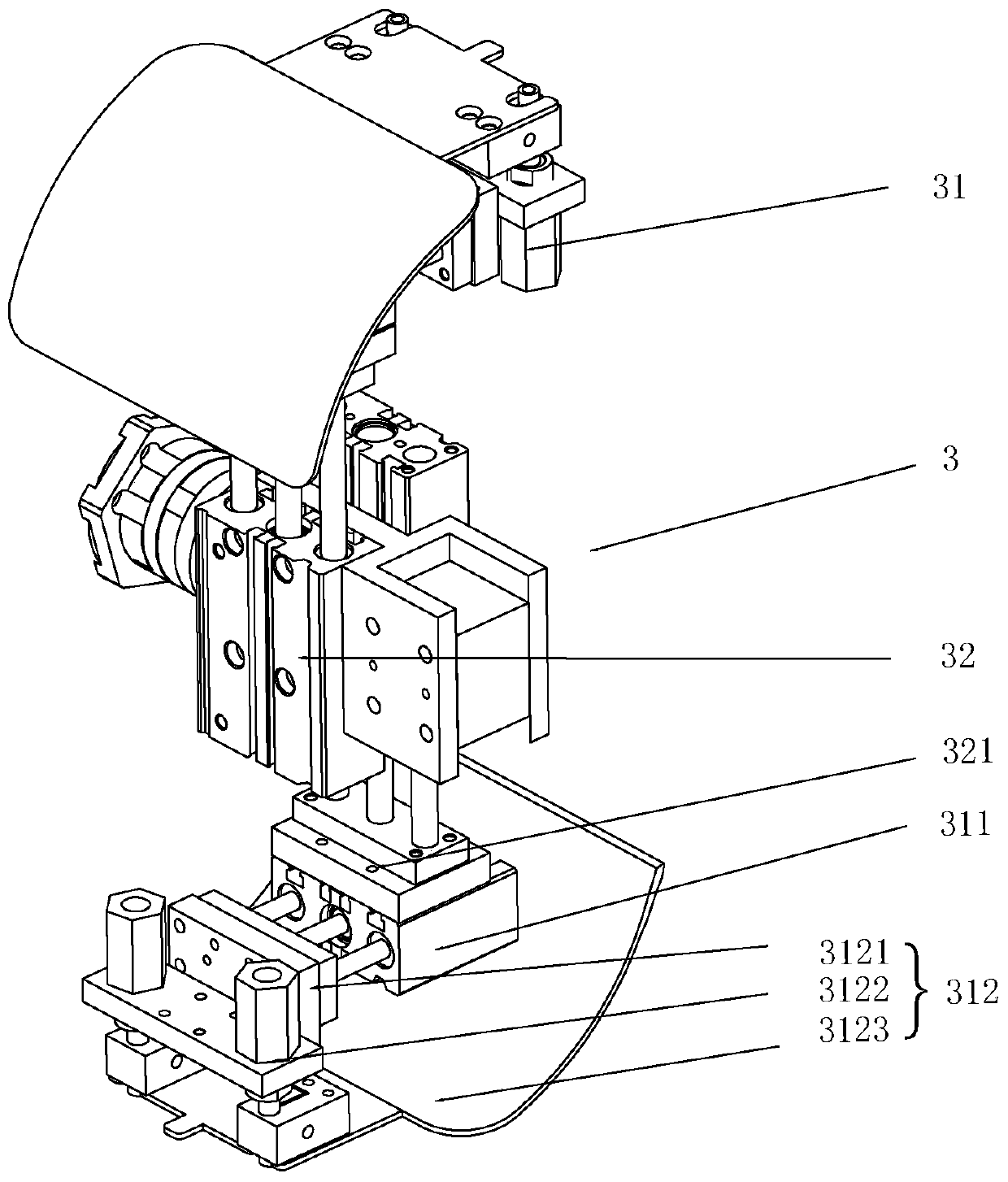

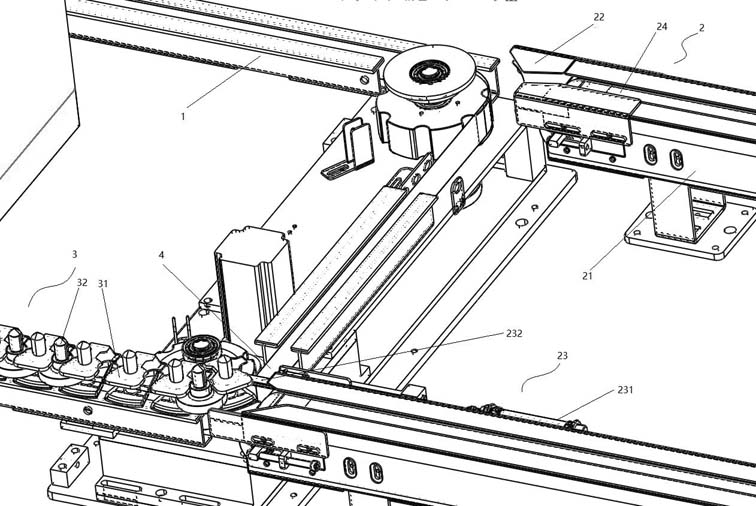

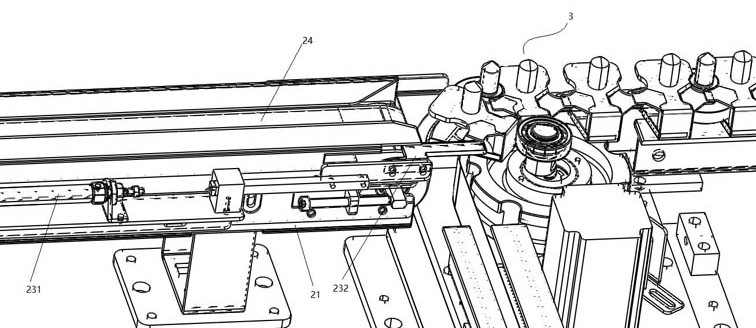

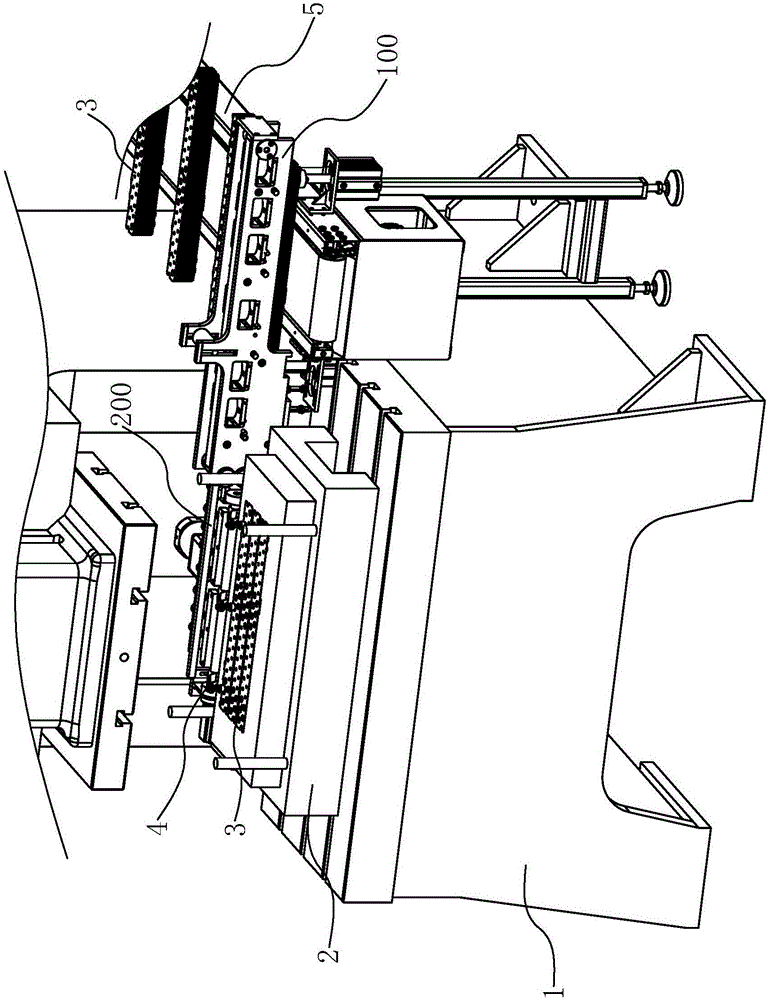

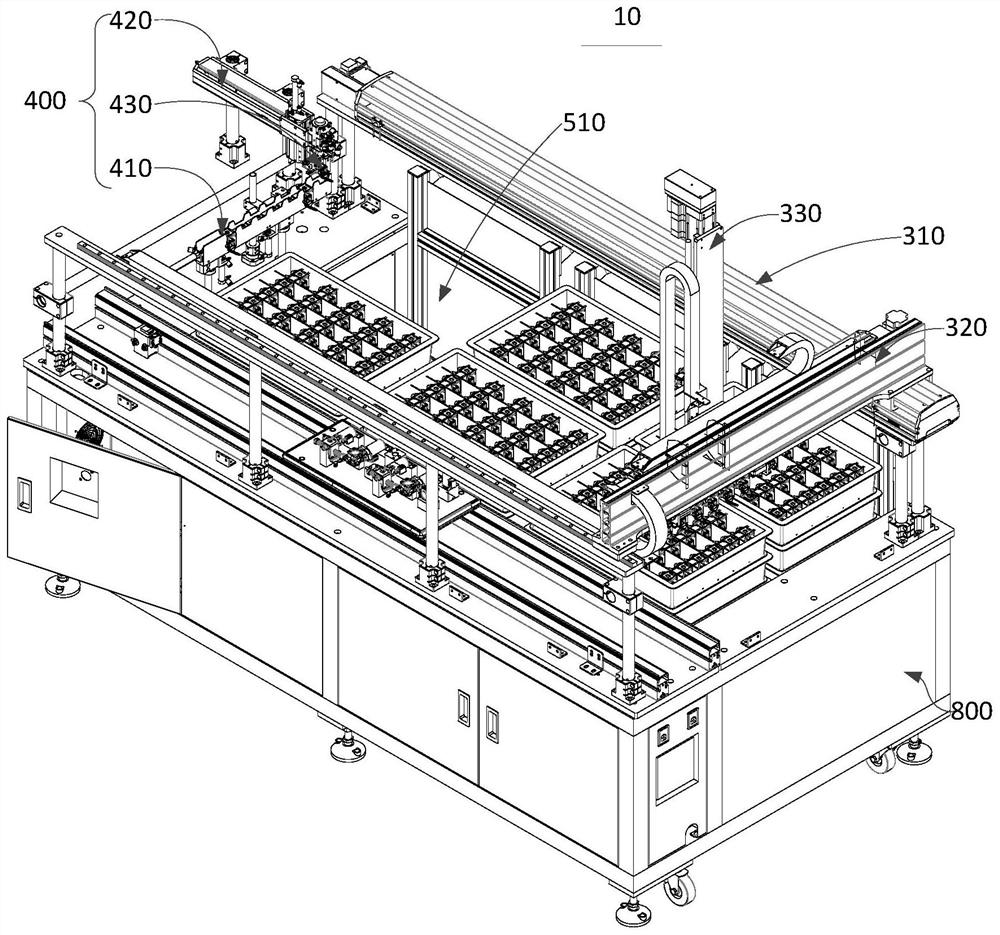

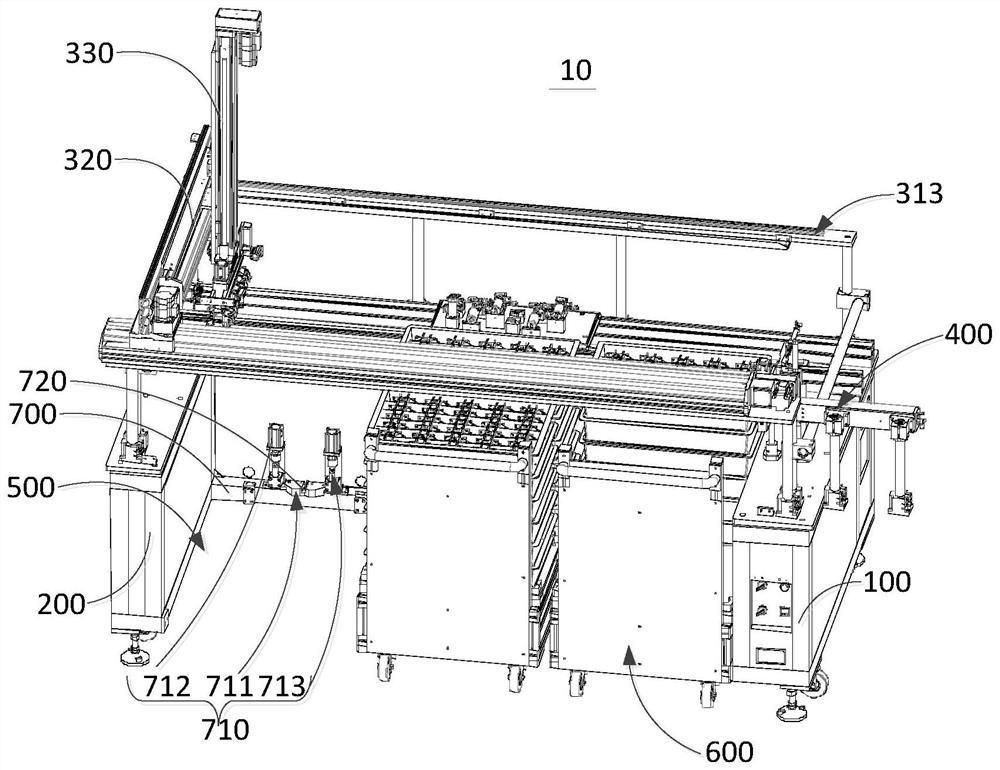

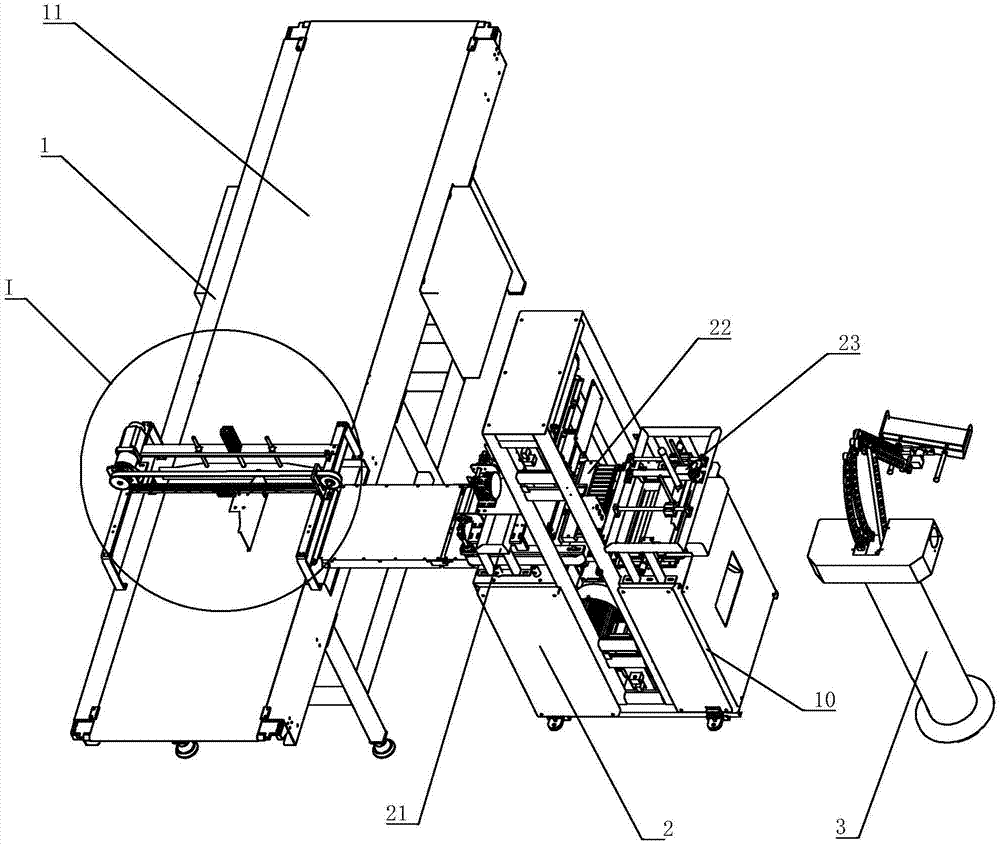

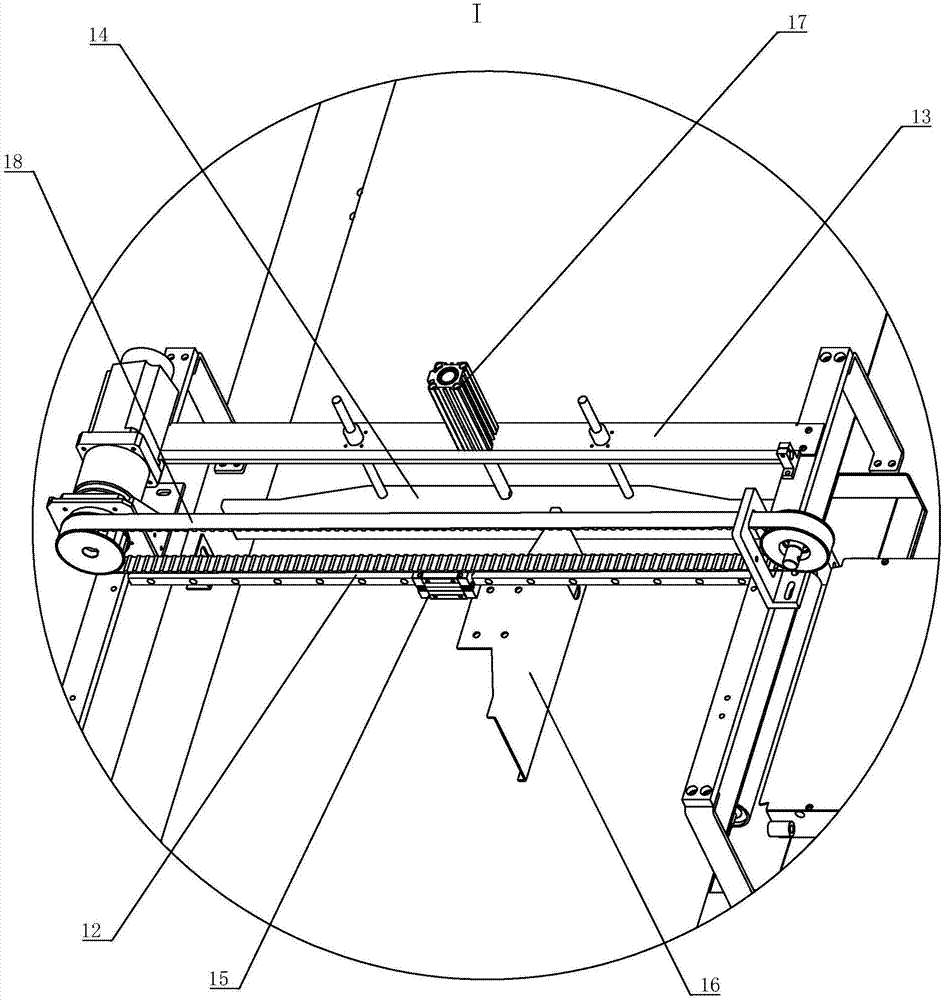

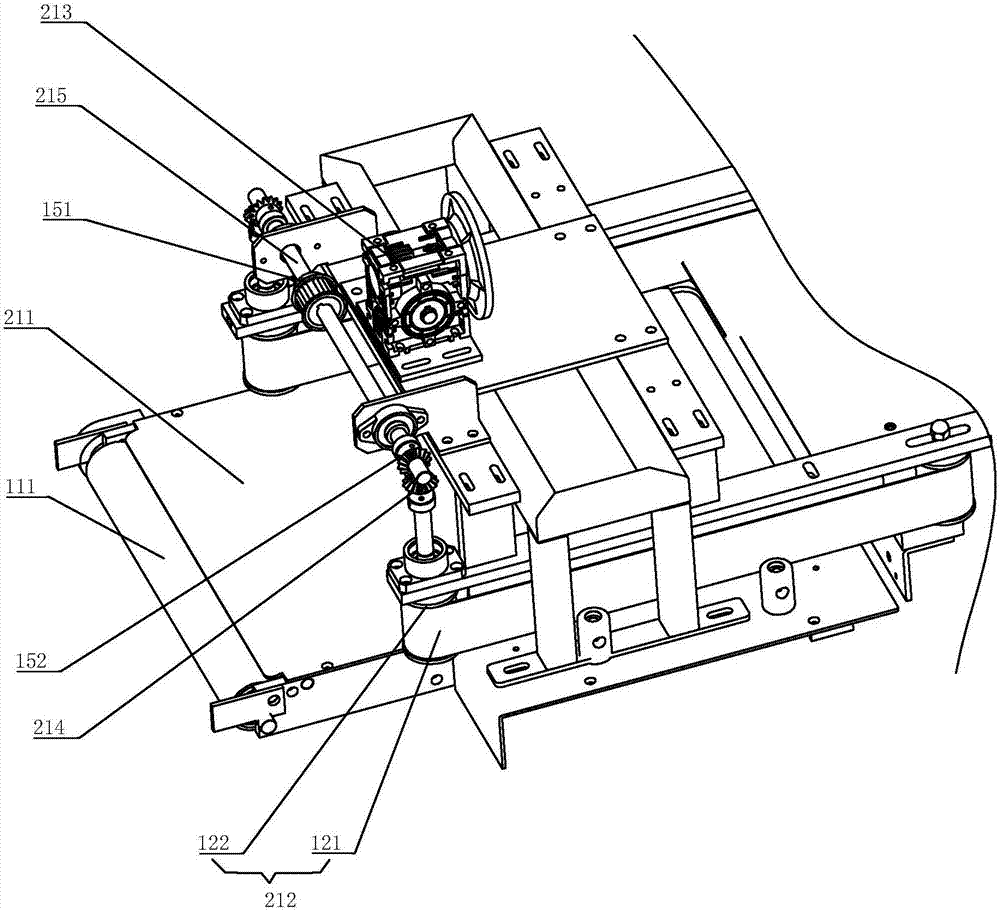

Silicon wafer transshipment and loading device and silicon wafer transshipment and loading method based on same

InactiveCN107887314AAutomate the transferReduce breakage rateFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon chip

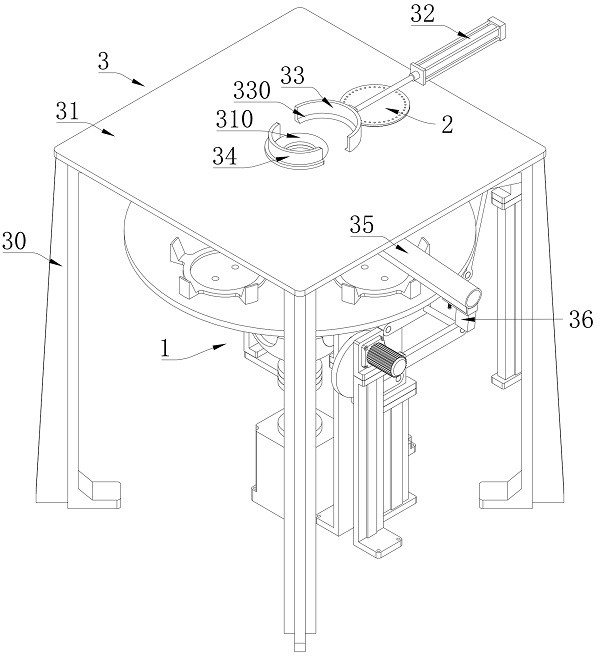

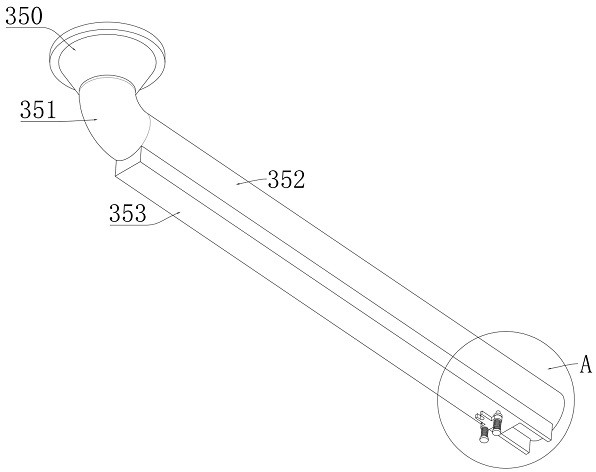

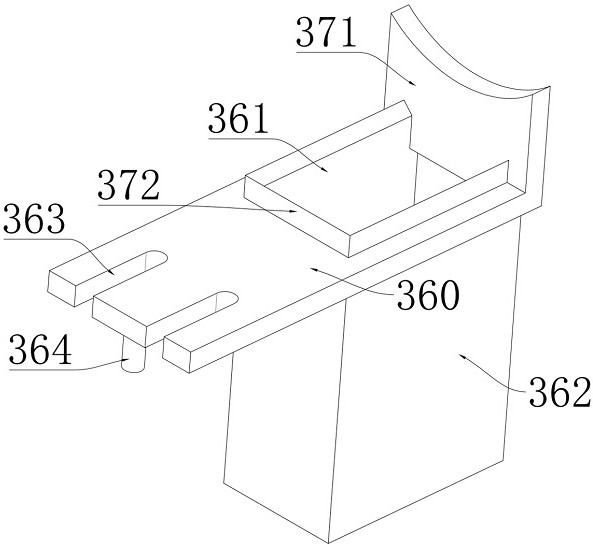

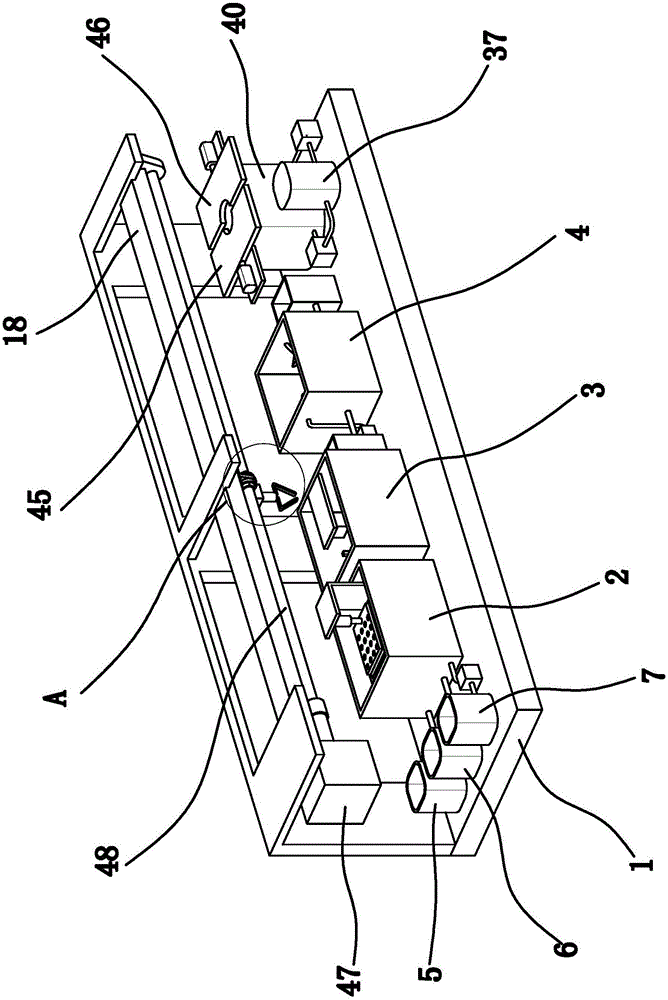

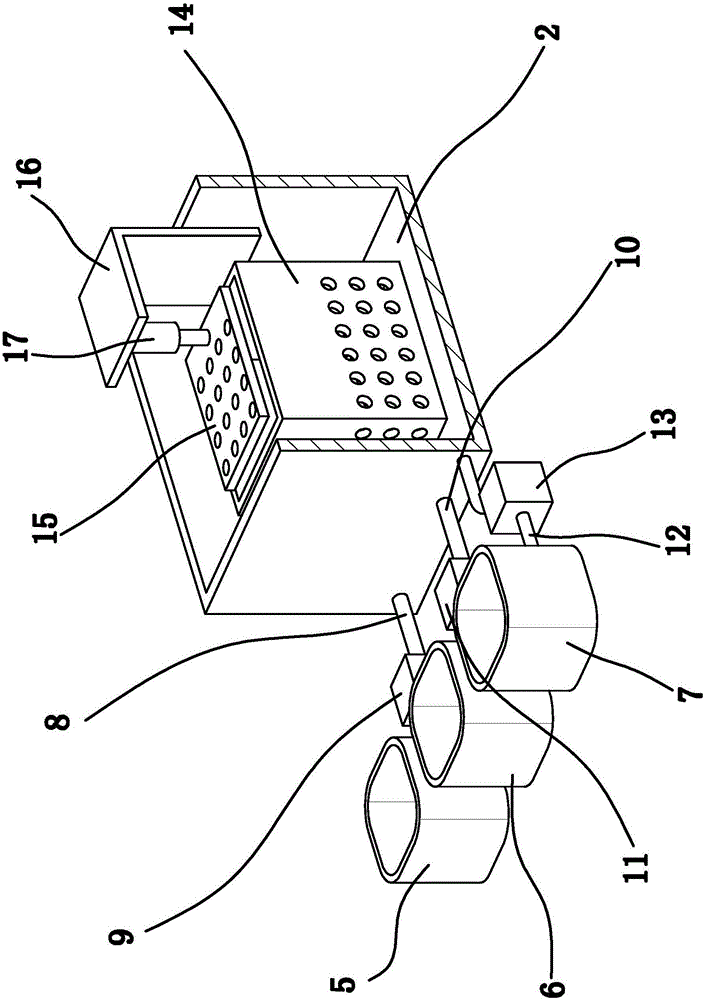

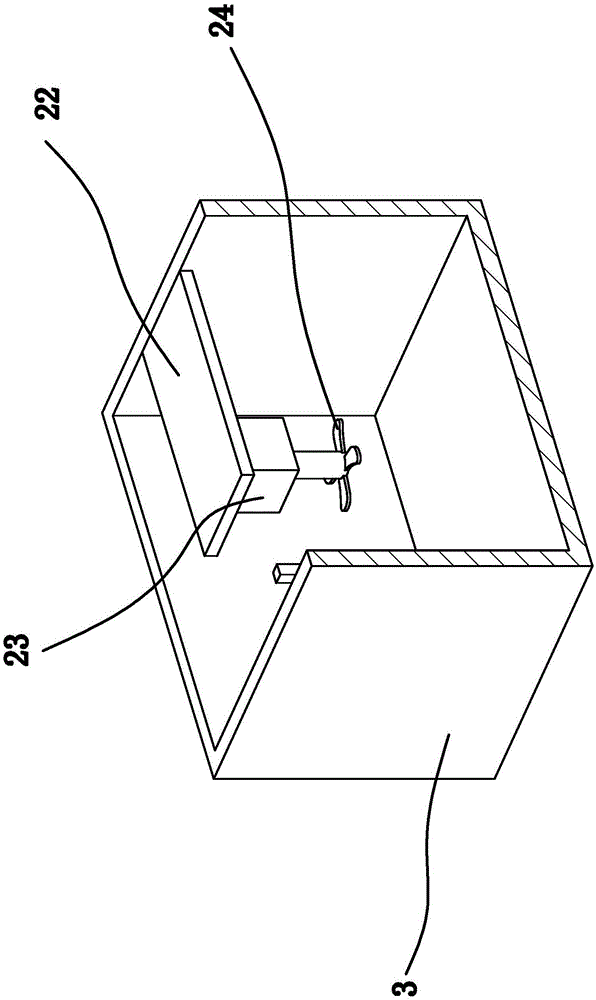

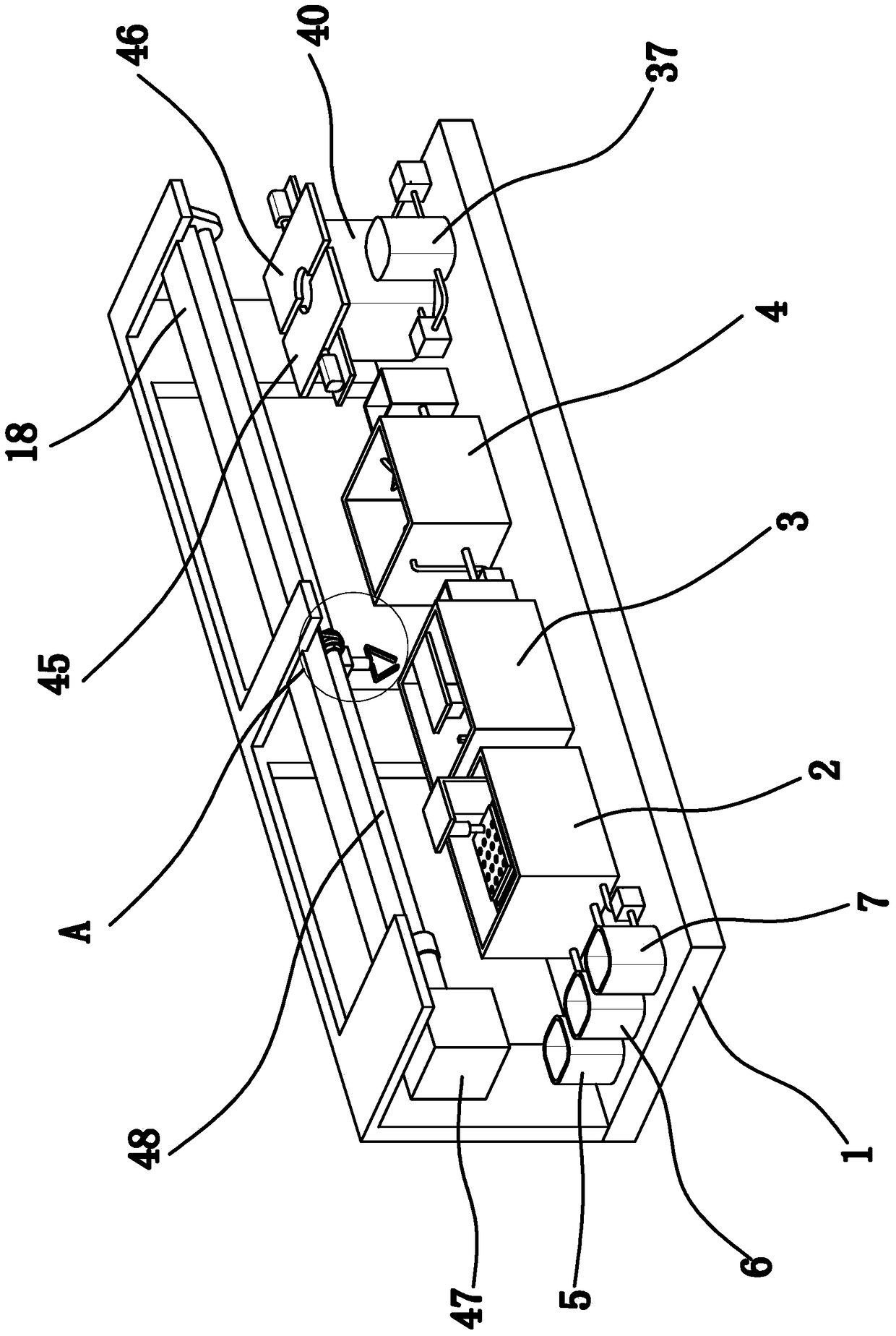

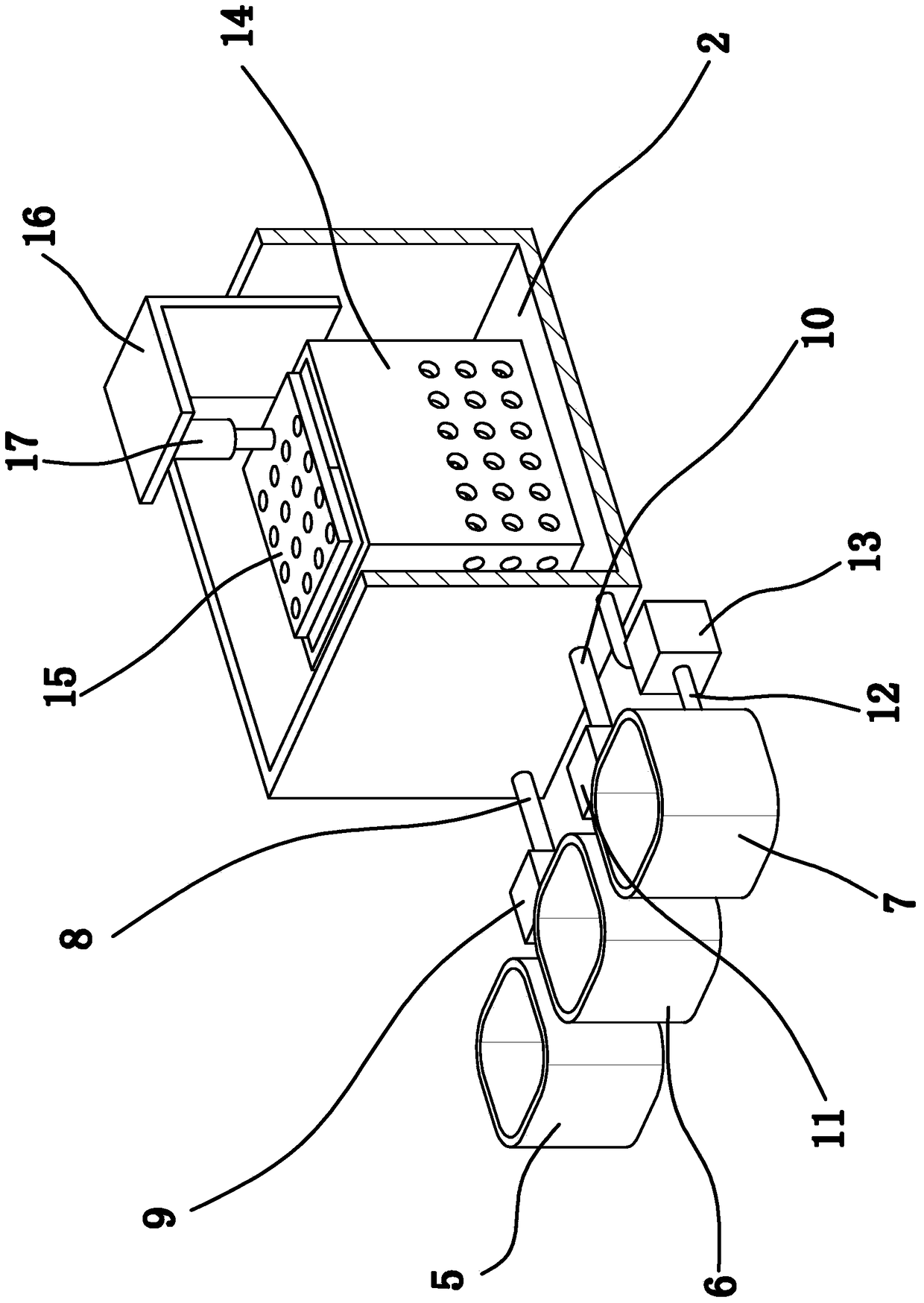

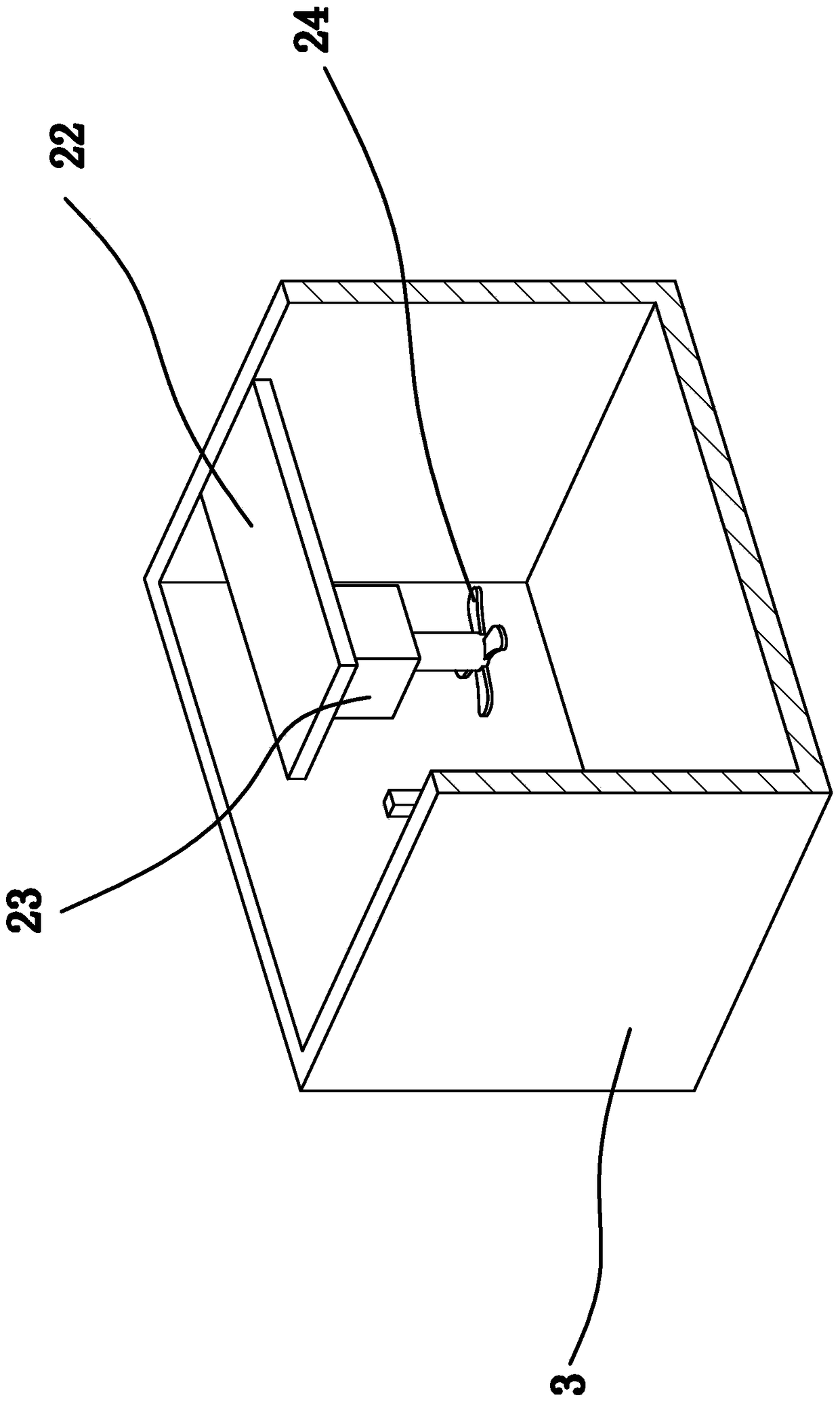

The present invention relates to a silicon wafer transshipment and loading device and a silicon wafer transshipment and loading method based on the same. The device comprises a rack, two railboat positioning feeding and blanking systems, a flower basket channel transshipment system and a double-end transshipment manipulator system. The two railboat positioning feeding and blanking systems are respectively arranged at left and right sides of the rack, the flower basket channel transshipment system is arranged at the middle portion of the rack and located between the two railboat positioning feeding and blanking systems, and the double-end transshipment manipulator system crosses the left and right sides of the rack and is located above the railboat positioning feeding and blanking systems and the flower basket channel transshipment system.

Owner:HEBEI JING LONG SUN EQUIP

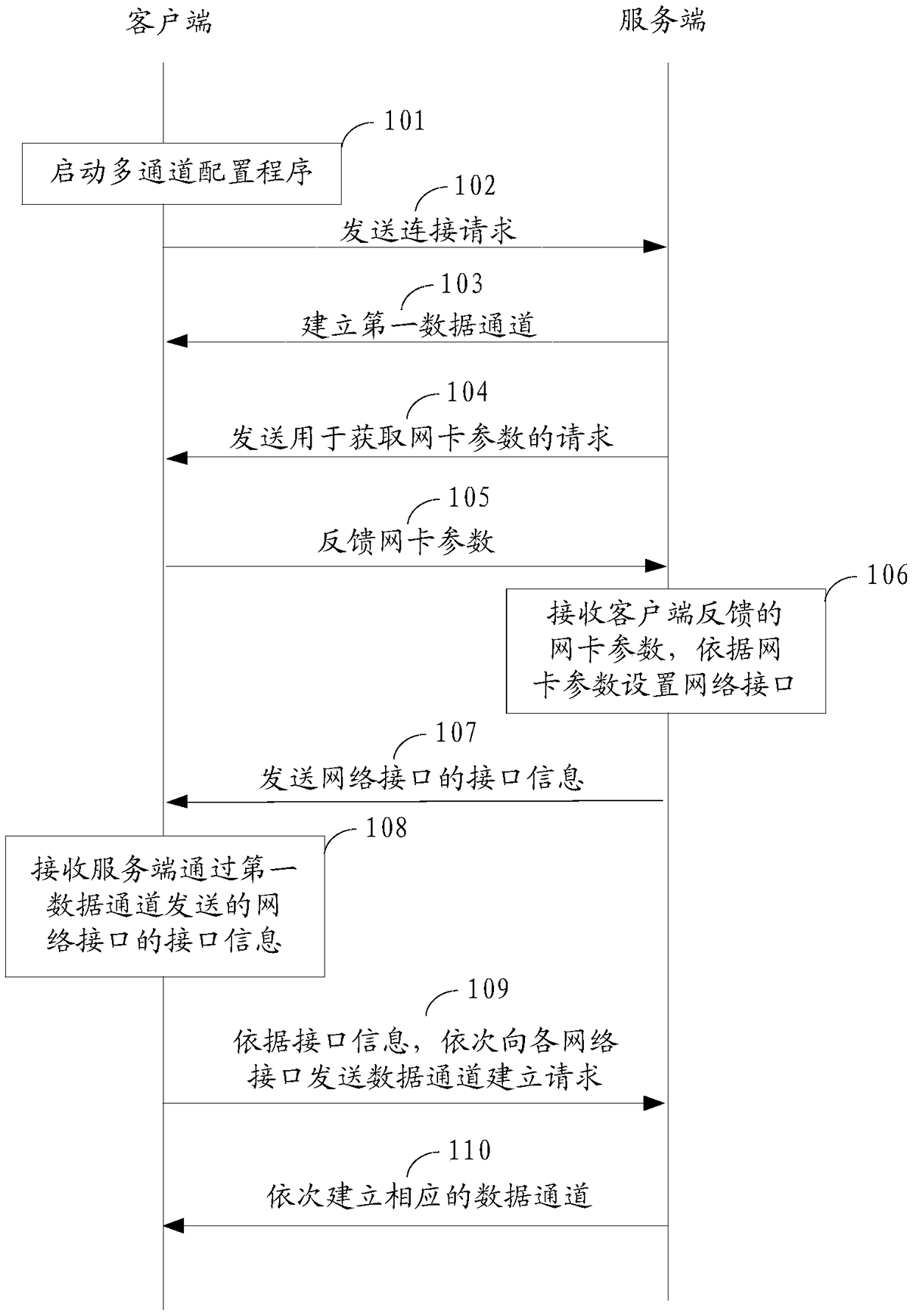

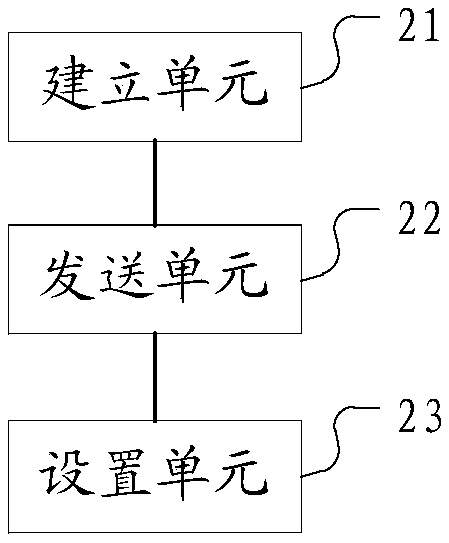

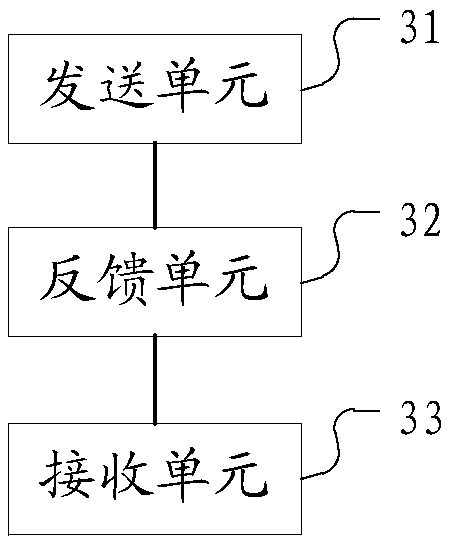

Multi-connection establishment method, device and system

InactiveCN109151082AImprove throughputImprove fault toleranceData switching networksClient-sideData channel

The embodiment of the invention discloses a multi-connection establishment method, a device and a system. The client starts a multi-channel configuration program and transmits a connection request toa service end. When receiving the connection request, the service end establishes a first data channel. And the service end transmits a request for acquiring network card parameters to the client. Thenetwork interface is set according to the received network card parameters, and the interface information of the network interface is sent to the client. According to the interface information, the client side transmits the data channel establishment request to each network interface of the server side successively. When the server side receives the data channel establishment request sent by theclient side, the corresponding data channel is established in turn. According to multiple data channels, without interrupting the application services, automatic transfer of network path failures is realized, the method ensures the uninterrupted business, and improves the reliability of the cluster system. Moreover, the service end can use multiple data channels at the same time, which increases the throughput of the server and the fault-tolerant ability of the network.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

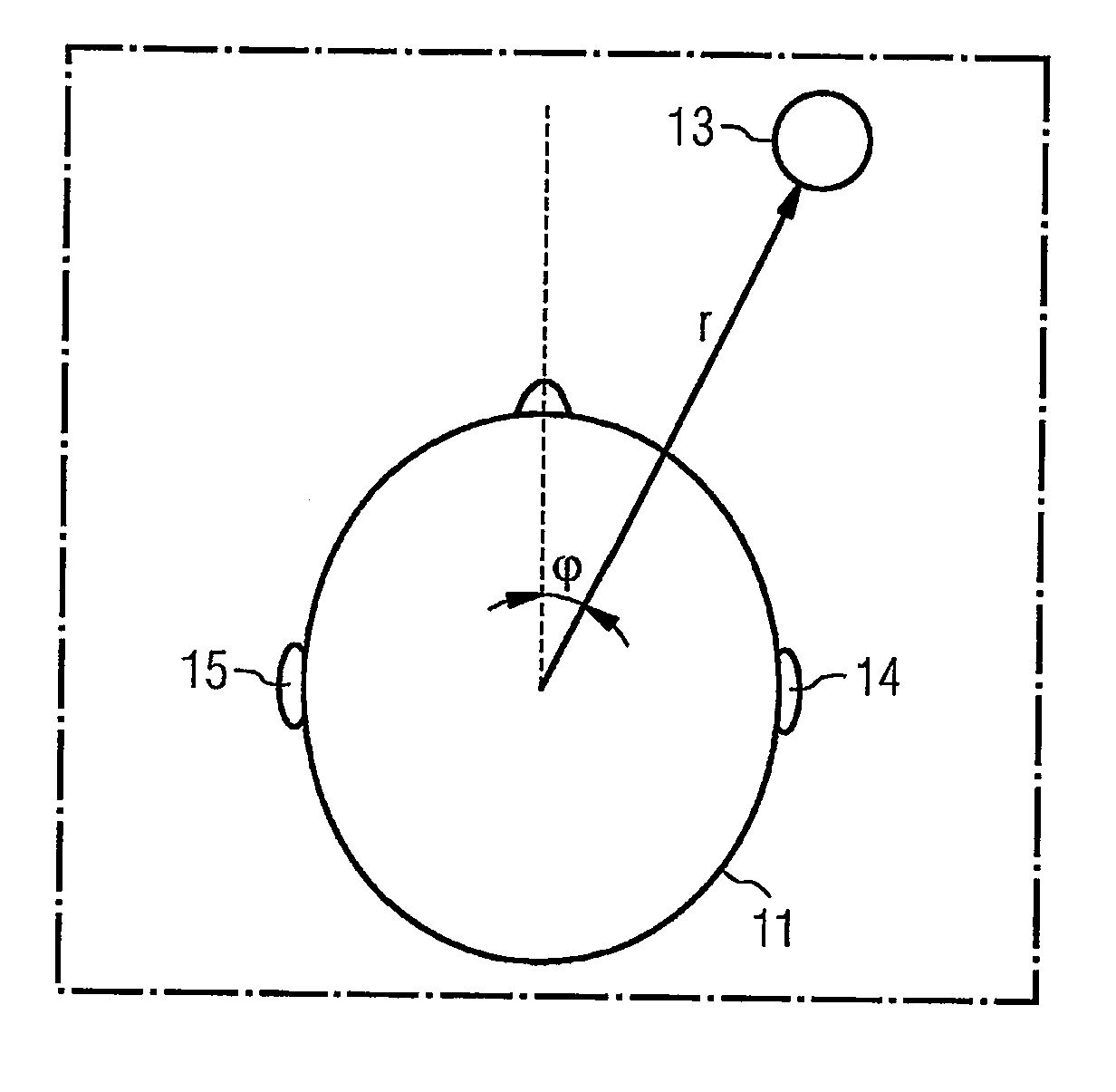

Spartial audio processing method, a program product, an electronic device and a system

ActiveUS20070291967A1Improve abilitiesAutomate the transferTwo-channel systemsLoudspeaker spatial/constructional arrangementsComputer scienceReproduction

Owner:QUALCOMM INC

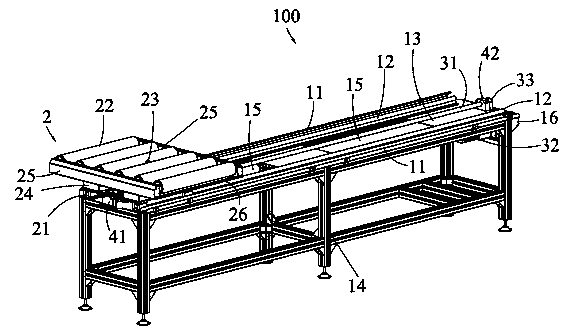

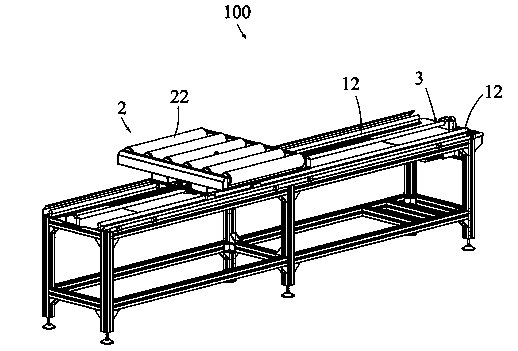

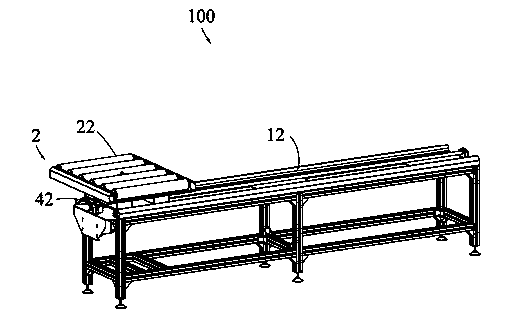

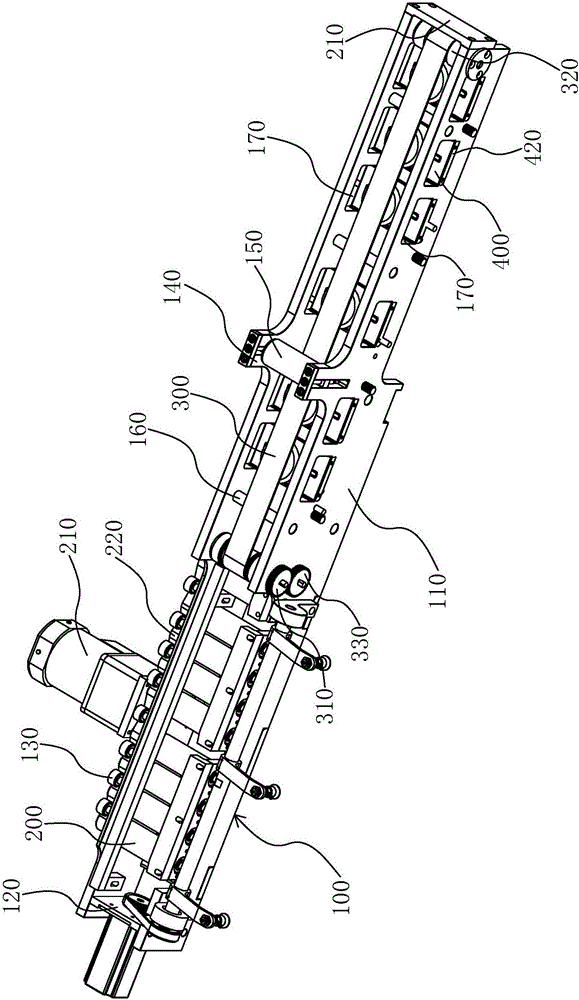

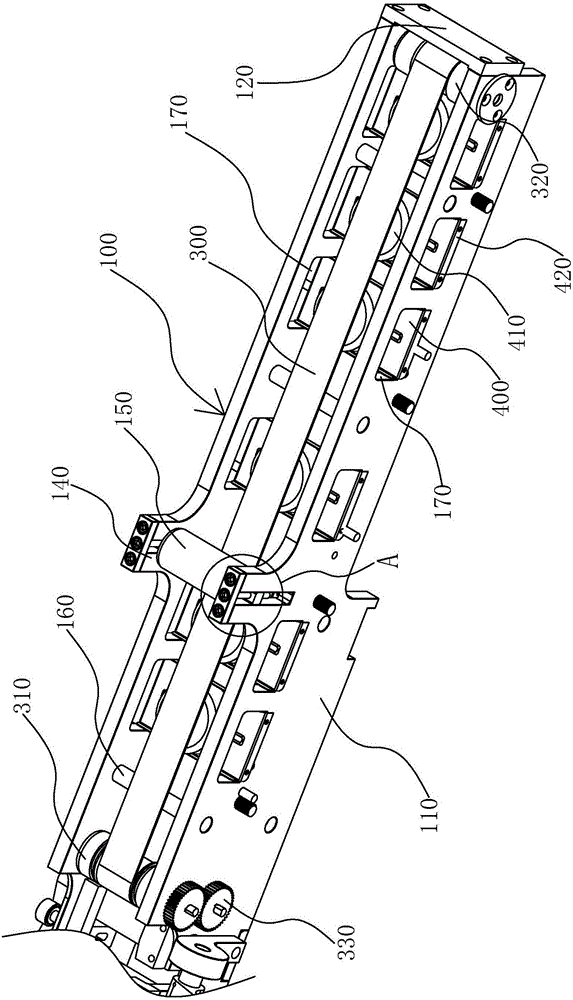

Conveying device on automated production line

InactiveCN103569613AAutomate the transferLow costControl devices for conveyorsMechanical conveyorsProduction lineEngineering

The invention relates to a conveying device on an automated production line, which is used for transferring finished products. The conveying device comprises a guide rail, a tray and a translation driving device, wherein the guide rail extends along the lengthwise direction, the tray is arranged on the guide rail, the translation driving device is used for driving the tray to move along the guide rail, the tray is provided with a rolling element, an induction device and a lifting driving device, and when the induction device induces that the finished products reach the rolling element, the lifting driving device drives the rolling element to ascend, and further the translation driving device drives the tray to move along the guide rail. The finished products are automatically transferred through the above design, and the conveying device has the advantage of low cost.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

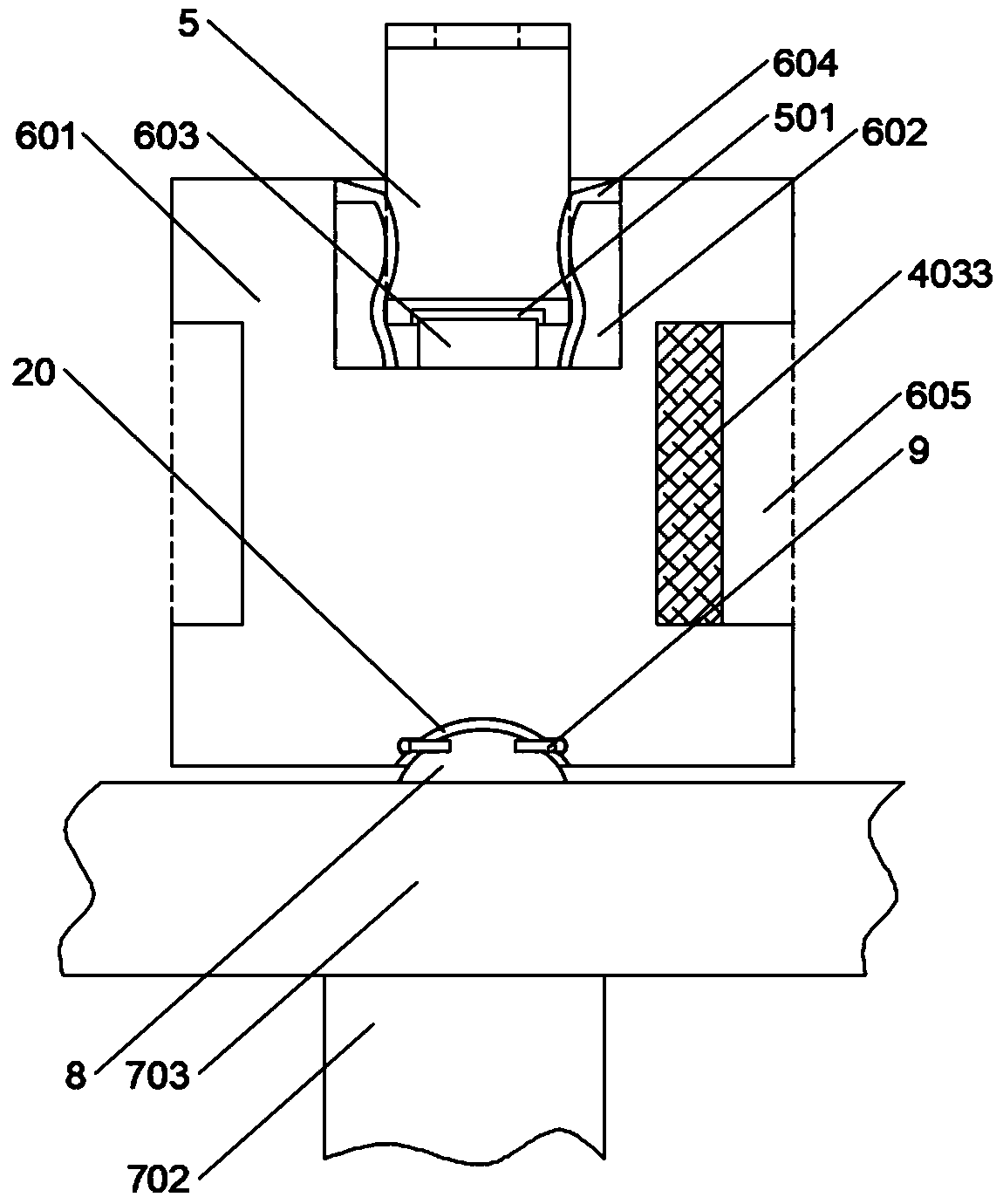

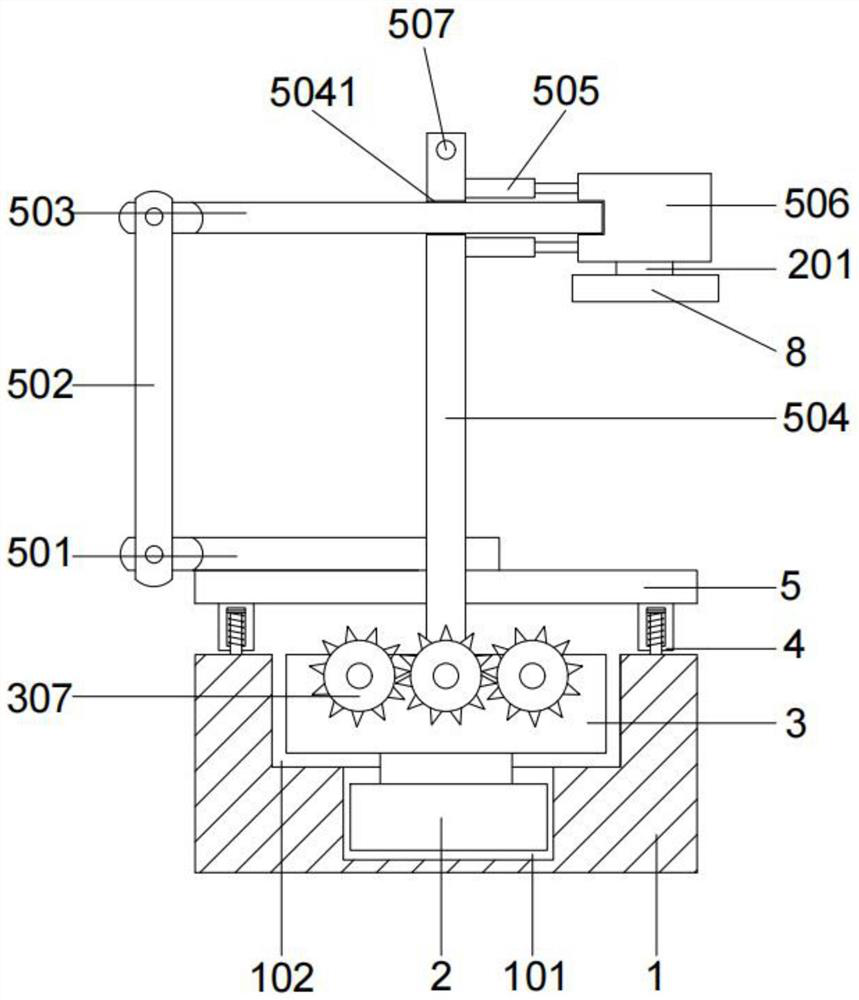

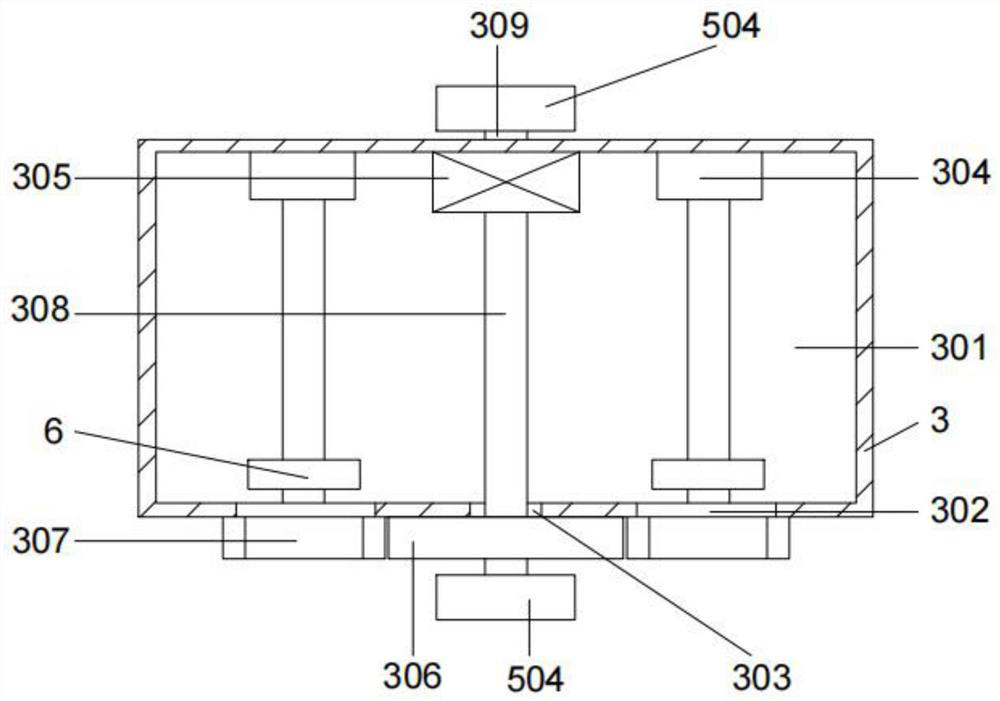

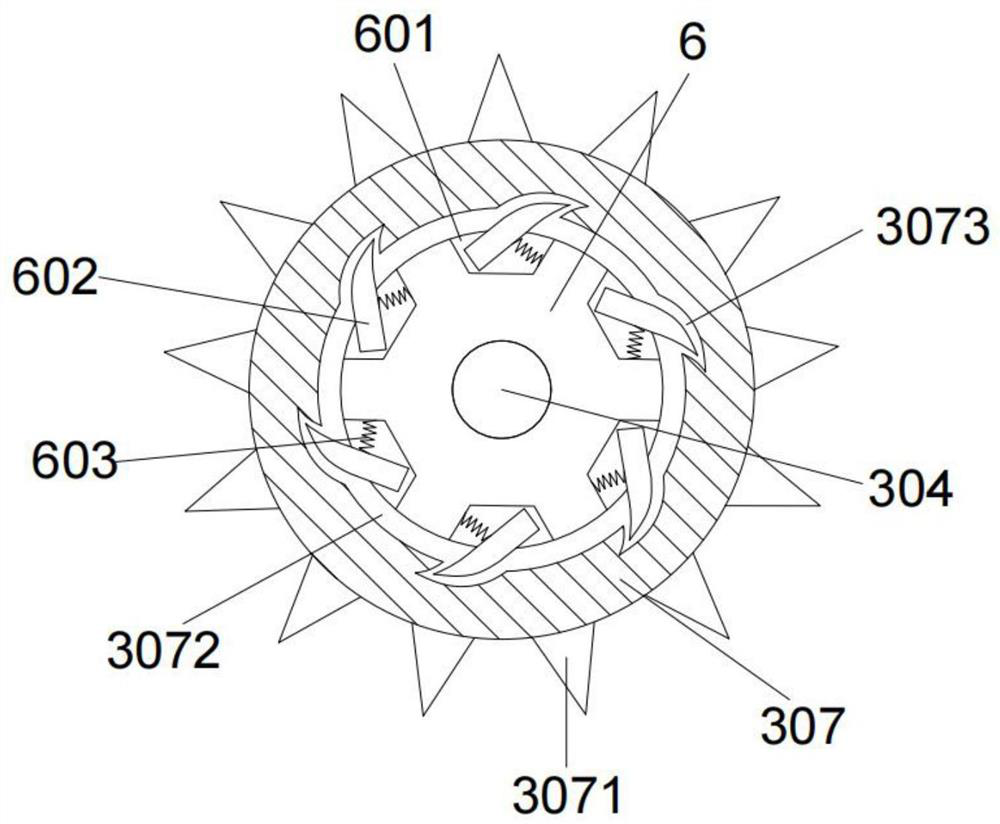

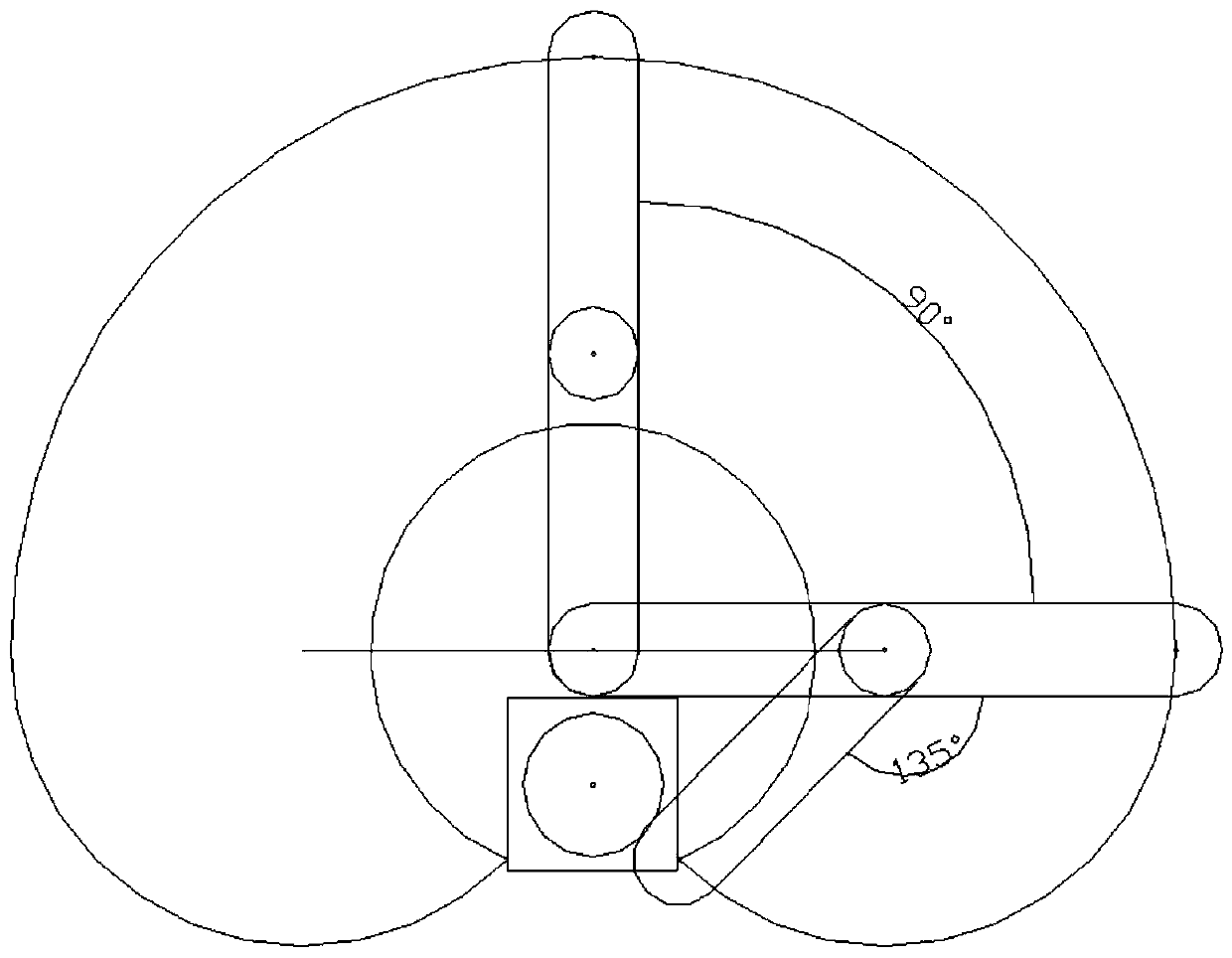

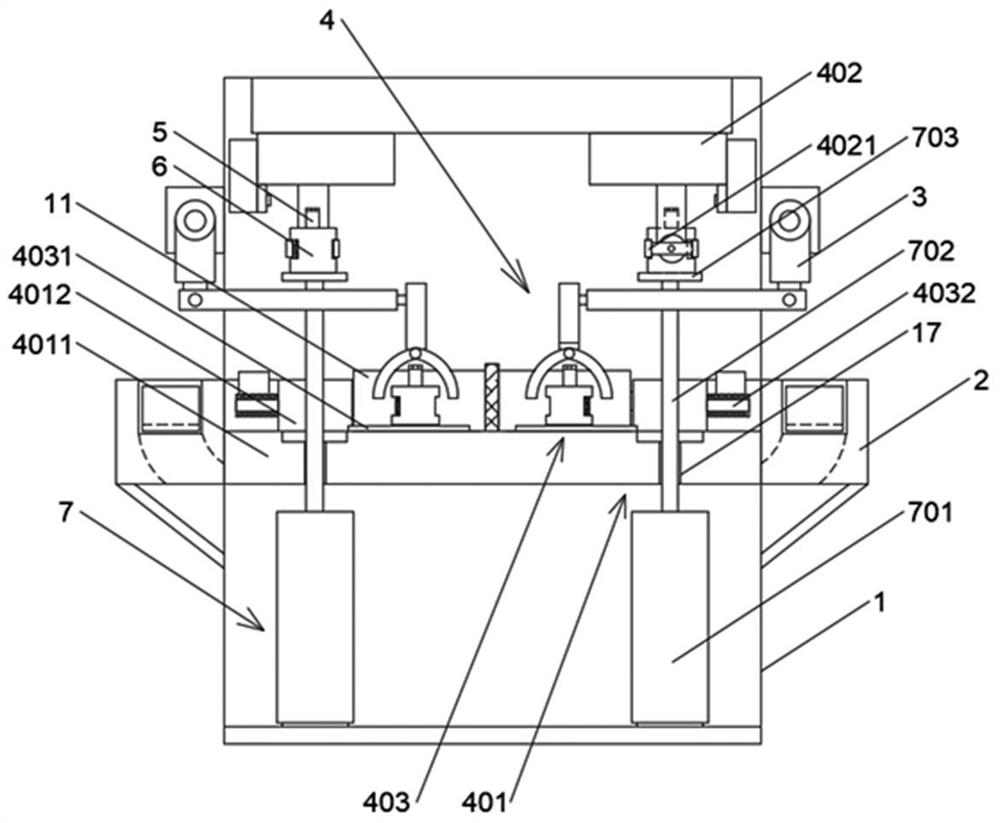

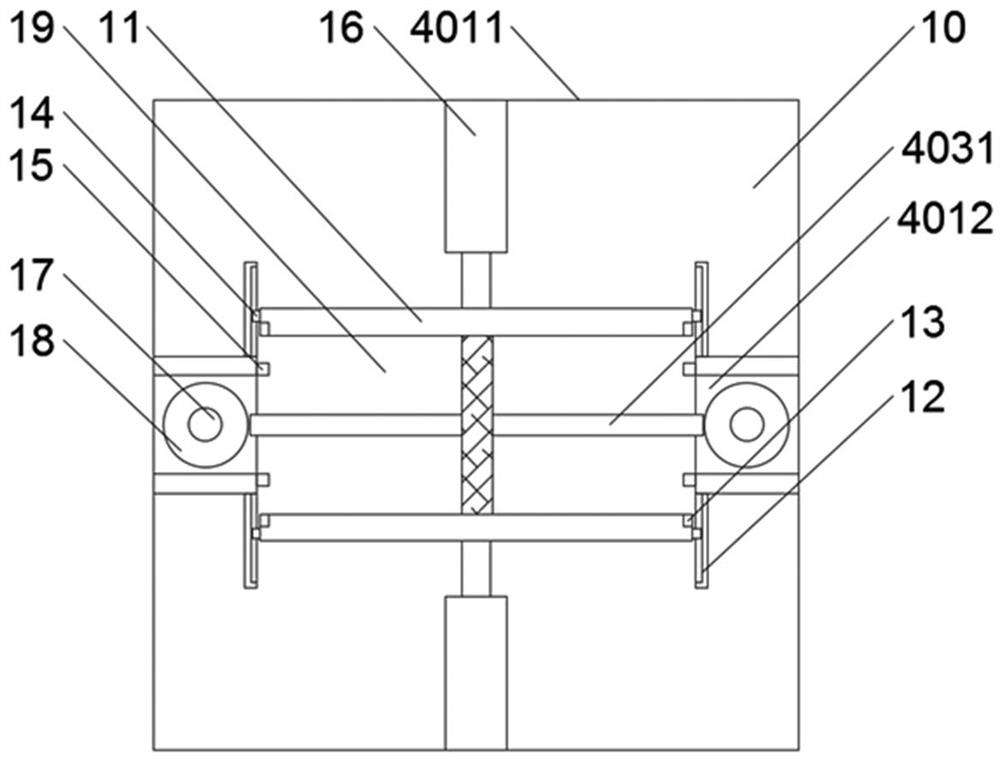

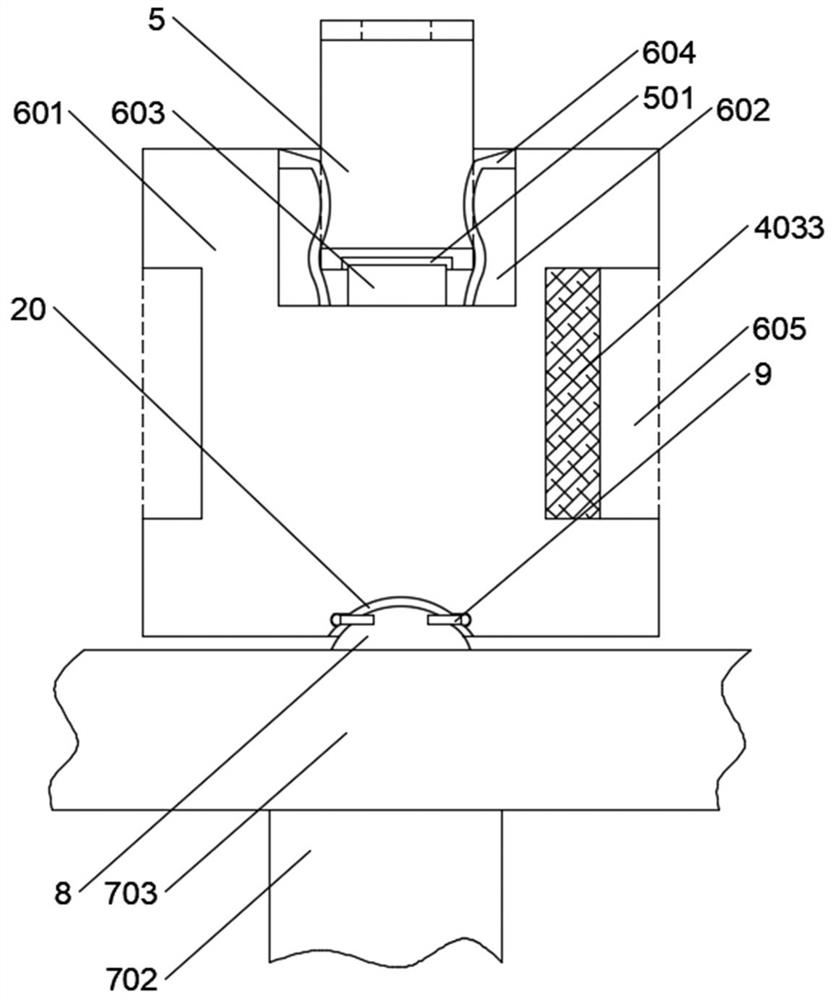

Electric fastener self-pairing type intelligent assembling robot and assembling method

ActiveCN111421332AAutomate the transferRealize regulationAssembly machinesMetal working apparatusRobot handControl engineering

The invention discloses an electric fastener self-pairing type intelligent assembling robot and an assembling method. A robot body is included. Two components forming a fastener are subjected to transferring and direction adjustment through pairing bases assembled to the components. The components can disengage from the pairing bases under the action of external force. Each of the two sides of therobot body is provided with a mechanical arm for transferring the corresponding pairing base loading the component, a transfer pairing mechanism for conducting direction adjustment on the corresponding pairing base loading the component, and an automatic assembling mechanism for assembling the component obtained after direction adjustment. The fastener assembling method comprises the steps that the mechanical arms and the transfer pairing mechanisms are sequentially used for conducting conveying and direction adjustment on the pairing bases loading the components, the automatic assembling mechanisms are used for assembling the two components, and the purpose of automatic assembling of fasteners with complex appearances is achieved.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

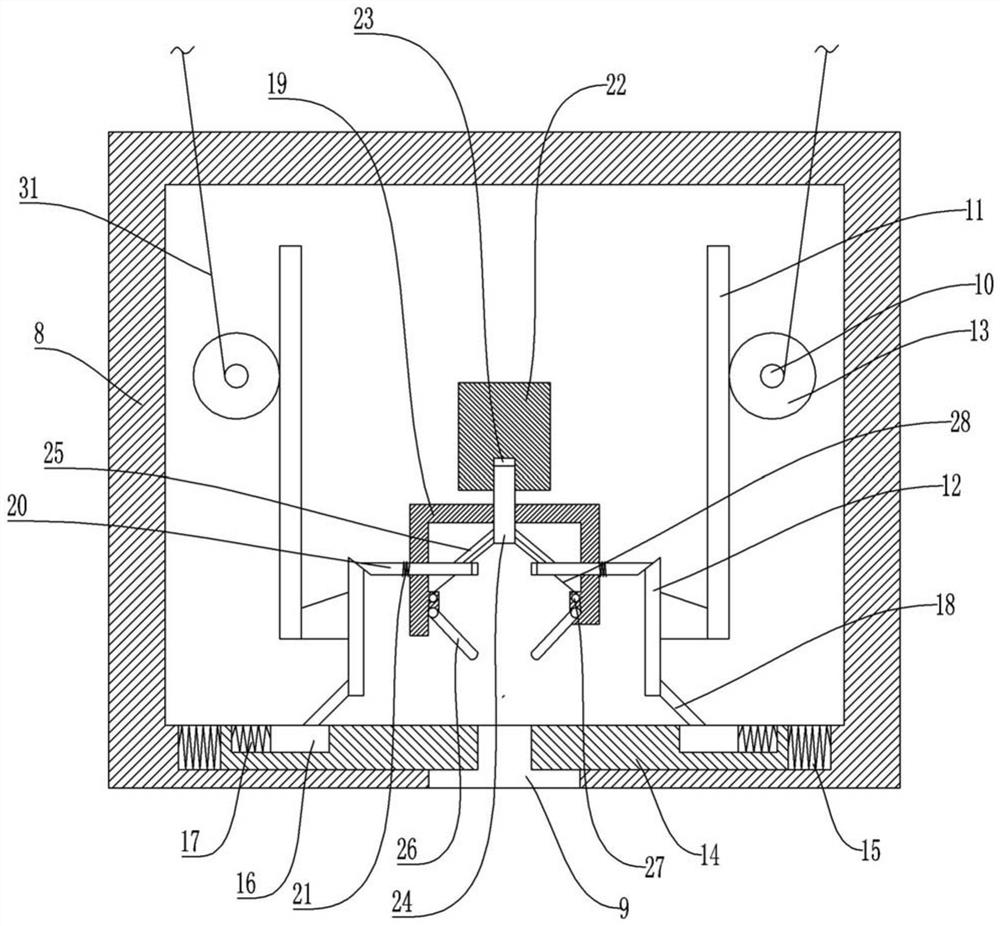

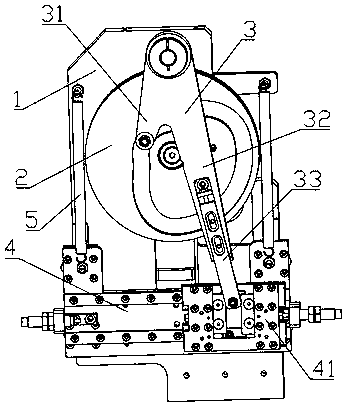

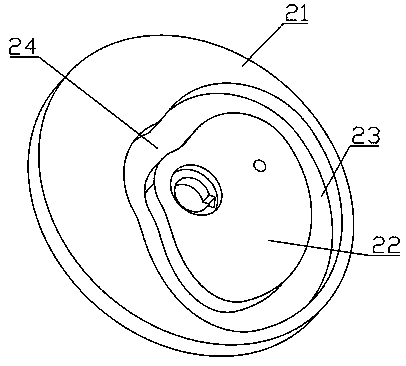

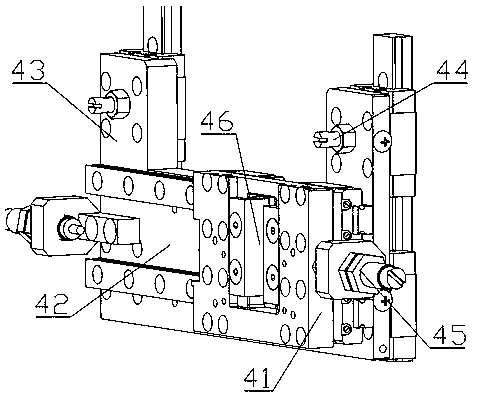

Magnetic suction type workpiece grasping precise positioning device

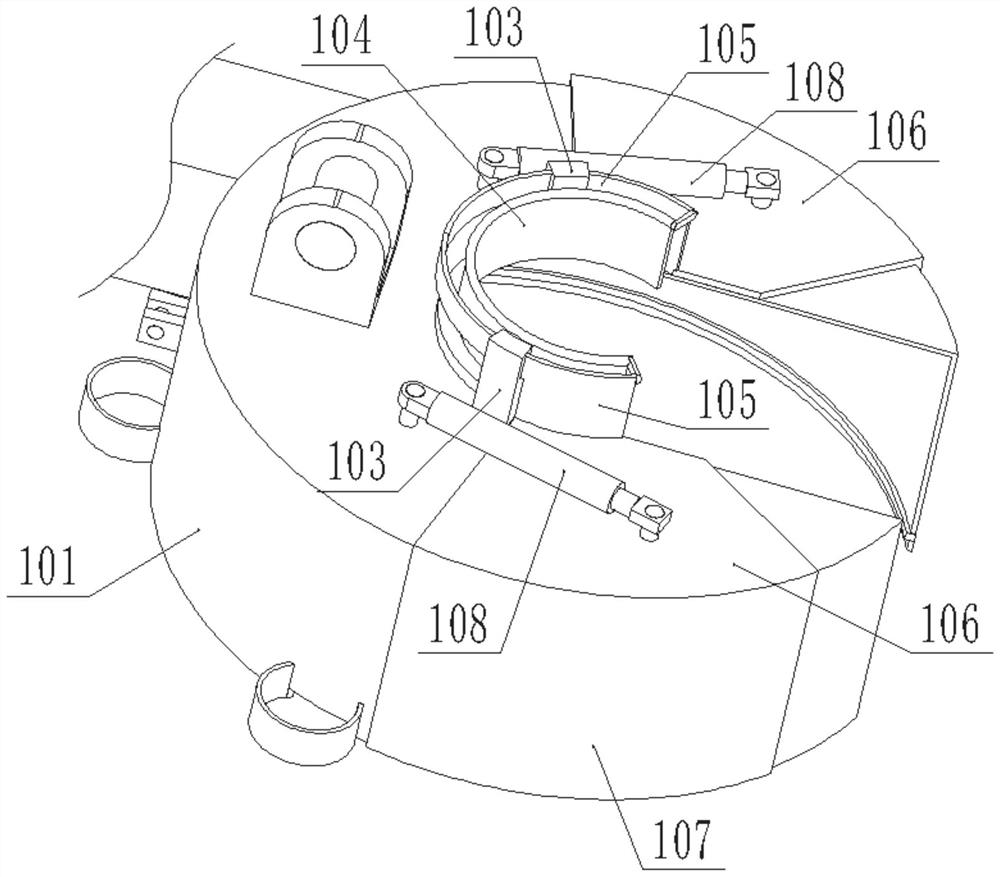

PendingCN111747112AAccurate grippingEasy to operateConveyorsControl devices for conveyorsCircular discEngineering

The invention relates to a magnetic suction type workpiece grasping precise positioning device. The magnetic suction type workpiece grasping precise positioning device includes a feeding mechanism, apiece-movement mechanism, a correction mechanism and a fine positioning mechanism; the feeding mechanism includes a feeding frame for stacking workpieces; and the piece-movement mechanism includes anelectromagnetic suction assembly and a transfer assembly for driving the electromagnetic suction assembly to move back and forth between the feeding frame and the correction mechanism. The purpose ofthe invention is to provide a magnetic suction type workpiece grasping precise positioning device applied to the automatic feeding of disc-shaped workpieces, which can transfer arbitrary stacked workpieces and realize accurate positioning. The advantages of the magnetic suction type workpiece grasping precise positioning device are as follows: the magnetic suction type workpiece grasping precise positioning device includes the feeding mechanism, the piece-movement mechanism, the correction mechanism and the fine positioning mechanism, the piece-movement mechanism can absorb the workpieces arbitrary stacked on the feeding mechanism and correct the front and back directions through the correction mechanism, and finally, precise positioning is performed by the fine positioning mechanism, which facilitates the subsequent processing operations or precise grasping by mechanical arms, so that automatic feeding is realized.

Owner:福州鸿基自动化设备有限公司

Vertical conveying system for bread processing

InactiveCN107696133AAutomate the transferIncrease productivityMetal working apparatusConveyor partsEngineeringPush out

The invention discloses a vertical conveying system for bread processing. A front conveying belt pushing device and a rear bread cutting and conveying machine are connected and mounted to finish vertical conveying for bread processing; breads are stopped at a connected position of the bread cutting and conveying machine by a baffle of the conveying belt pushing device, the breads are pushed out ofa first conveying belt of the conveying belt pushing device in the transverse direction and conveys the breads into a second conveying belt which is perpendicular to the bread cutting and conveying machine by a vertical push plate of the conveying belt pushing device, automated transfer of the breads between two conveying belts which are perpendicular to each other is realized, then the breads enter the bread cutting and conveying device, then are cut, are pushed by the pushing device and then are conveyed to a next mechanism, by the structure of the conveying system, the production efficiency and the sanitation safety conditions are improved, and moreover, the labor cost in a production process can be reduced effectively.

Owner:江门市神川自动化设备有限公司

Discharging mechanical arm of mechanical hand device

InactiveCN113650008AExpand the scope of workHigh accuracy of angle adjustmentProgramme-controlled manipulatorGripping headsRobot handRobotic arm

The invention provides a discharging mechanical arm of a mechanical hand device. The discharging mechanical arm comprises a power base. Shock absorption mechanisms are symmetrically arranged on the left side and the right side of the upper end of the power base, an adjusting cavity is formed in the middle of the upper end of the power base, the shock absorption mechanisms are connected with a mechanical arm mechanism, and the mechanical arm mechanism comprises a guide mechanism and a clamping mechanism. The guide mechanism is connected with the clamping mechanism through a second motor, an angle adjusting mechanism is rotationally arranged inside the adjusting cavity and connected with the guide mechanism, and electric devices in the power base, the mechanical arm mechanism, the clamping mechanism and the angle adjusting mechanism are connected with a control piece. The discharging mechanical arm solves at least one of the problems that firstly, manual transfer or carrying operation is generally adopted at present, the labor cost is high, time and labor are wasted, the improvement of the production efficiency is not facilitated, and potential safety hazards exist in manual carrying; and secondly, when a mechanical arm transports an object, if the weight of the object is too large, the transportation process of the mechanical arm is unstable.

Owner:康凤林

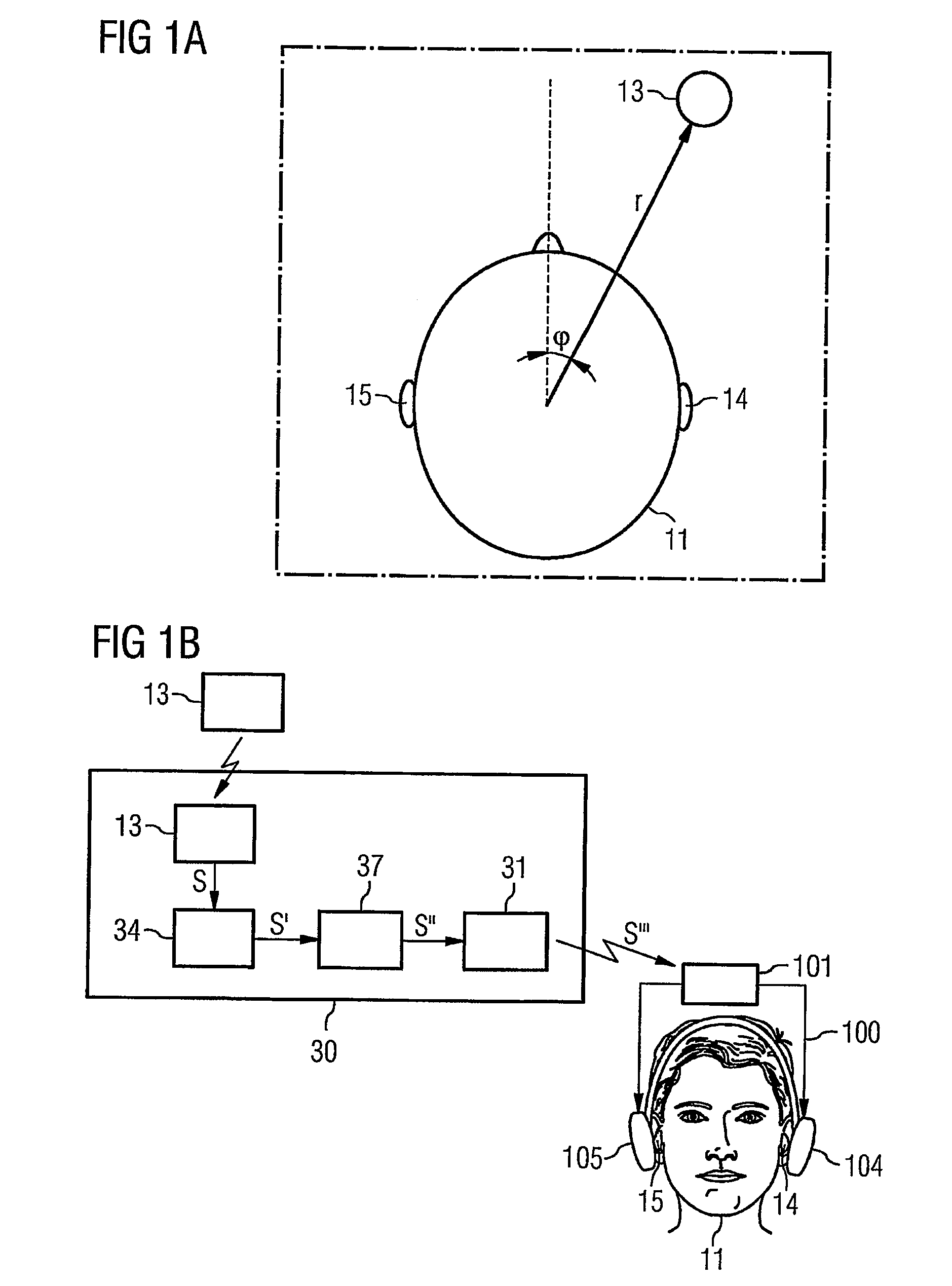

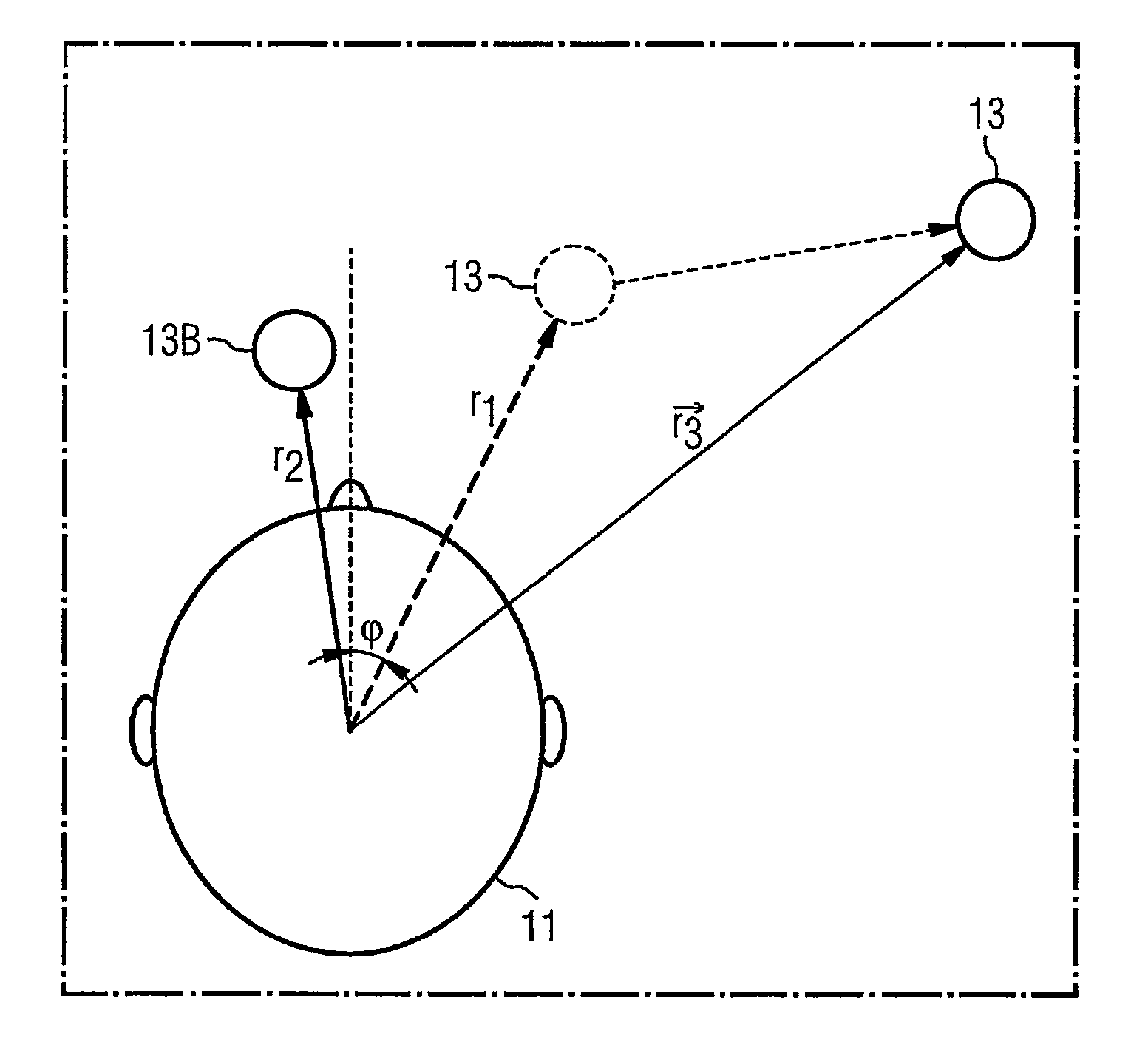

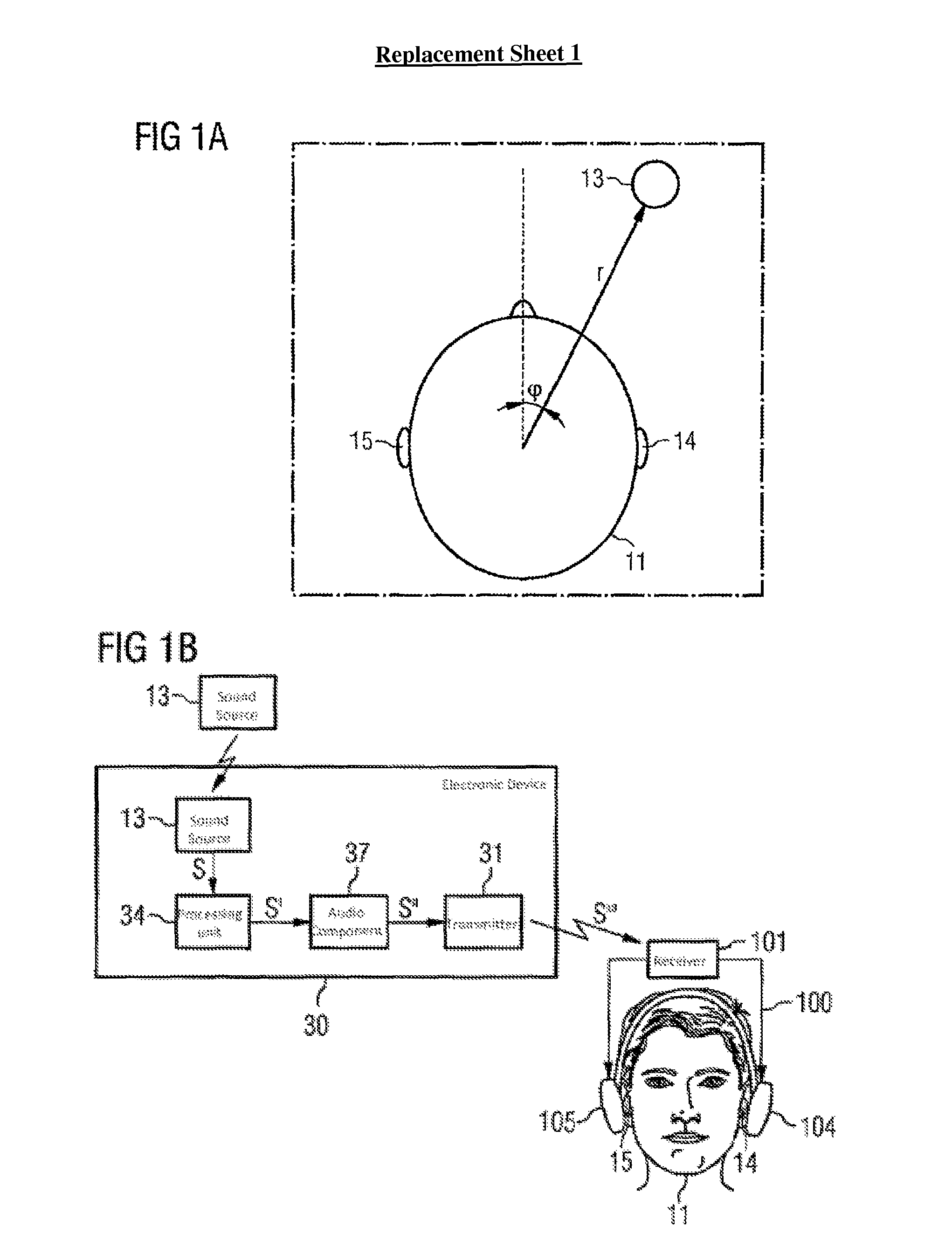

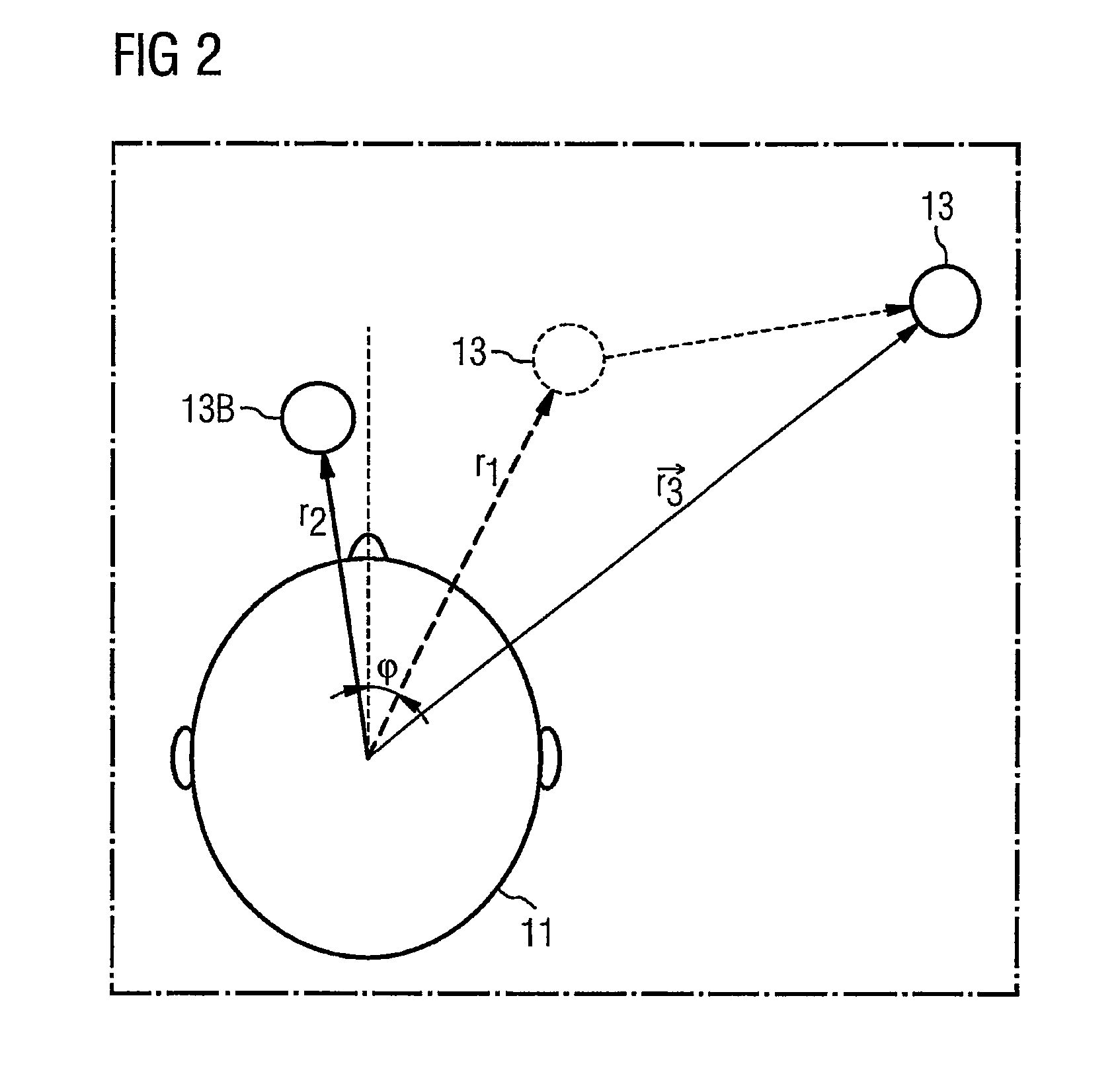

Spatial audio processing method, program product, electronic device and system

ActiveUS8488820B2Automate the transferImproving user comfortTwo-channel systemsLoudspeaker spatial/constructional arrangementsSignal transfer functionTransferring (function)

A method comprises the steps of: receiving a first audio signal (S1); generating a digital representation (S1″) of the first audio signal (S1) by applying a head-related transfer function (HRTF) in a first sound reproduction position (r1); and changing the first sound reproduction position (r1) to a second sound reproduction position (r3) in response to receiving a second audio signal S2) or a precursor signal for a second audio signal (S2).

Owner:QUALCOMM INC

Plastic bag tidying device

ActiveCN110182408ARealize the collectionAchieve finishingPaper article packagingBag making operationsCouplingCam

The invention provides a plastic bag tidying device. The plastic bag tidying device comprises a collecting device, a tidying device, a transfer device and a device frame, wherein the collecting device, the tidying device and the transfer device are fixed on the device frame; the collecting device comprises a front baffle, a guide shaft, a base, a guide shaft support, a rear baffle, a first motor,a cam shaft and a cam; the tidying device comprises a bag flattening plate, a connecting rod shaft, a sliding block, a linear guide rail, a crank, a crank shaft, a first coupler and a second motor; and the transfer device comprises a guide rod support, a guide rod, a transfer base, a lead screw nut, a lead screw, a support seat, a manipulator, a second coupler and a third motor. According to the plastic bag tidying device, plastic bag collecting, tidying and transferring are integrated, automation is achieved, and the plastic bag tidying device has the characteristics of simple structure, convenience in installation and use and the like.

Owner:ZHEJIANG UNIV OF TECH +1

PCR chip tray transfer and storage mechanism

InactiveCN112777102AAutomate the transferImplement storageConveyor partsMechanical conveyorsPhysicsEngineering

The invention discloses a PCR chip tray transfer and storage mechanism. The PCR chip tray transfer and storage mechanism comprises a mechanical clamping jaw used for grabbing a chip tray, a three-dimensional driving mechanism used for driving the mechanical clamping jaw to move and a storage bin used for storing the chip trays, wherein the interior of the storage bin is divided by a plurality of partition plates to form a plurality of storage chambers used for storing the chip trays in the vertical direction; and the mechanical clamping jaw comprises a mounting base, two clamping rods slidably arranged on the mounting base in the Y direction, and a clamping jaw driving mechanism used for driving the two clamping rods to move in the Y direction in order to be opened or clamped. According to the PCR chip tray transfer and storage mechanism, the chip trays are stacked and stored in the vertical direction through the storage bin, so that the space occupied by storage can be reduced; and through the cooperation of the mechanical clamping jaw and the three-dimensional driving mechanism, the chip trays can be transferred and stored into the storage bin, or the chip trays in the storage bin can be taken out and transferred to designated positions, so that automatic transfer and storage of the chip trays can be realized, and the working efficiency is improved.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Automatic glass tank production device

PendingCN112678520AAutomate the transferImprove work efficiencyCharge manipulationConveyor partsTransverse grooveMachine

The invention relates to the technical field of glass tank production. The automatic glass tank production device comprises a machine base, a fixing plate is arranged on the machine base, a transverse groove is formed in the fixing plate, and a transverse block is connected into the transverse groove in a sliding manner; a transverse hole is formed in the bottom of the transverse groove, a movable rod is in clearance fit with the interior of the transverse hole, and a clamping mechanism used for clamping a glass tank is arranged at the bottom of the movable rod; and a first power part used for driving the transverse block to move transversely and a second power part used for driving the movable rod to move vertically are further included. According to the scheme, the problems that at present, a worker clamps the top of the formed glass tank through a clamp and transfers the glass tank to a conveying mechanism, however, the arm of the worker feels aching after long-time operation, and the glass tank transfer work efficiency is affected are mainly solved.

Owner:CHONGQING XINGBAOXING GLASS PROD CO LTD

Picking and overturning structure, transferring device and a full-automatic picking and conveying device

The invention discloses a picking and overturning structure, a transferring device and a full-automatic picking and conveying device. The picking and overturning structure comprises a base, a rotatingassembly which can freely rotate, and a picking assembly which is mounted on the rotating assembly, wherein the rotating assembly and the picking assembly are mounted on the base; and at least one rubbing mechanism set is arranged on the picking assembly and is driven by the picking assembly to telescope in a direction parallel to the radial direction of the rotating assembly. According to the picking and overturning structure, the rubbing mechanism is used for rubbing, separating and lifting a mask at the topmost layer of a mask pile layer, so that the mask is picked, and the whole mask picking process is simple and convenient, and the masks can be picked by pieces; the rotating assembly drives the rubbing mechanism to overturn to realize the overturning of the separated mask, so that the operation of the following mask folding process is conveniently carried out; the mask overturned by the rubbing mechanism is received by a receiving assembly, and thus the mask can be automaticallytransferred; and a conveying mechanism is used for receiving and conveying the mask received by the receiving assembly, so that the problem that the folding in later process is hard to carry out due to deflection deformation of the mask can be avoided.

Owner:ZHUHAI SHANGJIN INTELLIGENT MACHINERY EQUIP CO LTD

Automatic substrate loading mechanism

The invention discloses an automatic substrate loading mechanism. A chassis is arranged, and is sequentially provided with a containing area, a pick-up area and a transmission area; a supporting plate, perpendicular to the chassis, is fixed in the transmission area; one side face of the supporting plate is provided with a power source, and a transmission mechanism is arranged on the other side ofthe supporting plate, and is sequentially provided with a driven structure, a cam structure and a sliding mechanism from top to bottom; the output end of the power source passes through the supportingplate and drives the cam structure to rotate; the cam structure drives a short foot of the driven structure to do the curve arc-shaped motion; a long foot of the driven structure drives the sliding mechanism to do the lifting and horizontal movement; and the top end of the driven structure is in shaft connection with the upper portion of the supporting plate.

Owner:深圳市祁科作物科技有限公司

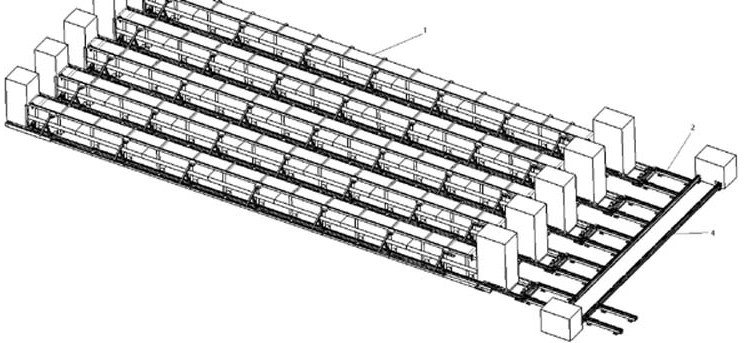

Spinning frame bobbin base parallel conveying system

PendingCN112323193AAutomate the transferNo need for manual handlingTextiles and paperBobbinEngineering

The invention relates to a spinning frame bobbin base parallel conveying system. The spinning frame bobbin base parallel conveying system is characterized by comprising a spinning frame set, a transition module and a distribution conveying frame; a plurality of spinning frame units are connected to the distribution conveying frame in parallel, a bobbin base can be switched among the spinning frameunits connected in parallel through cooperation of the distribution conveying frame and the transition module, and manual carrying is not needed. The bobbin base set is matched with a conveying belton a spinning frame, when a second bobbin base in the bobbin base set moves along with the conveying belt under clamping of first bobbin bases, and when the second bobbin base moves to a corner, a shifting fork unit is driven by a shifting fork driving cylinder to extend into an opening of a U-shaped clamping base, under the cooperation of the arc-shaped guide edges of guide baffles and the shifting fork unit, the second bobbin base embedded between the first bobbin bases is shifted out of the U-shaped clamping base to enter the a conveying frame unit, then the second bobbin base is conveyed to the distribution conveying frame through the conveying frame unit, then subsequent bobbin base distribution is conducted, and automatic transferring of the bobbin bases between the spinning frame units is achieved.

Owner:NANTONG JINCHI MECHANICAL ELECTRIC

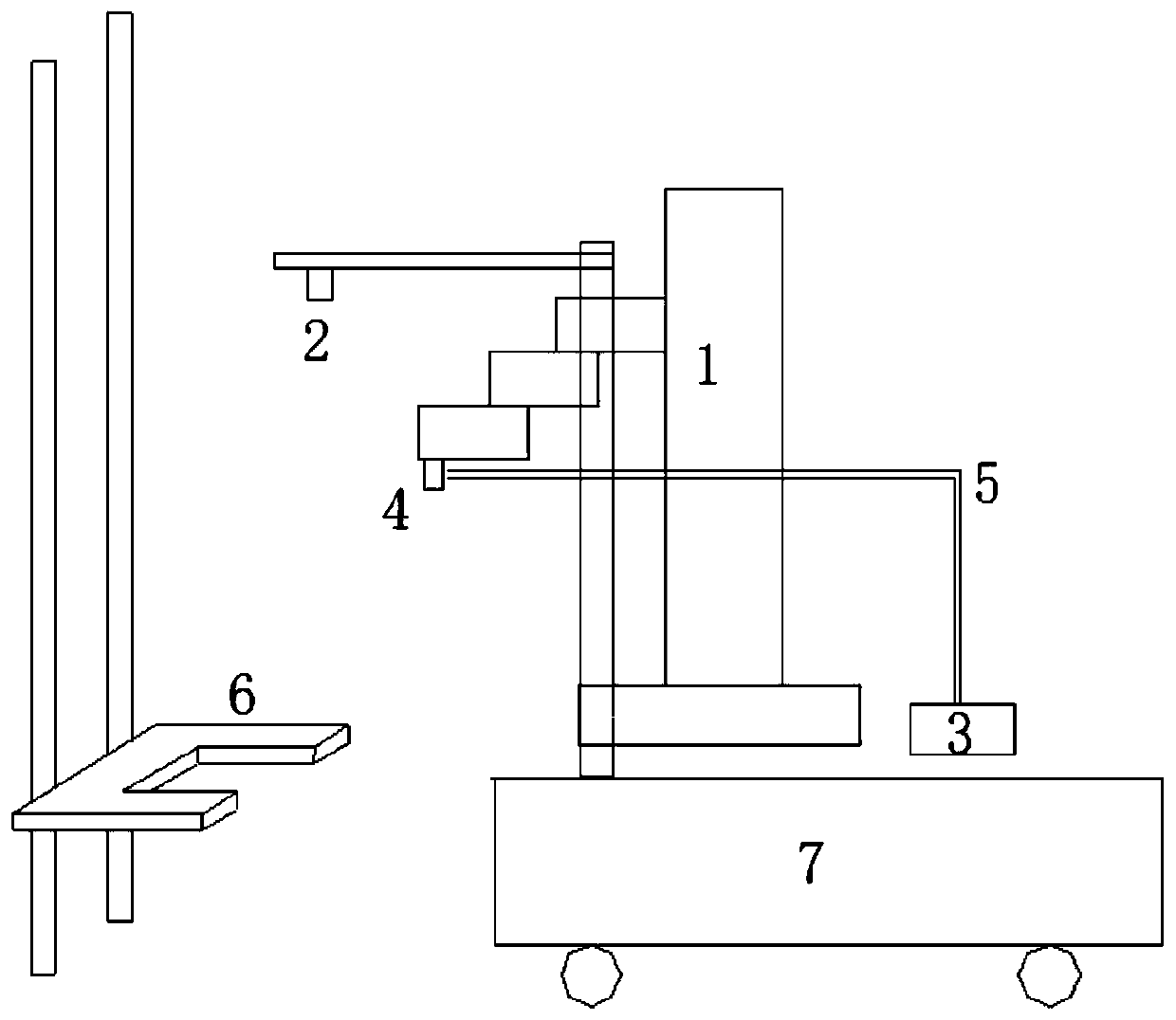

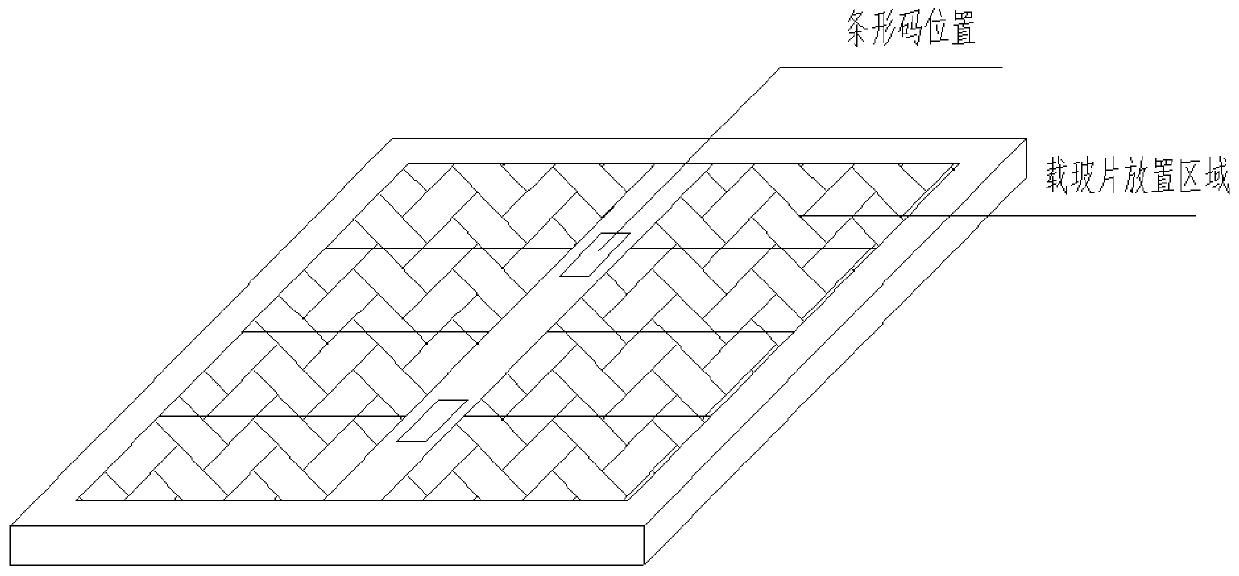

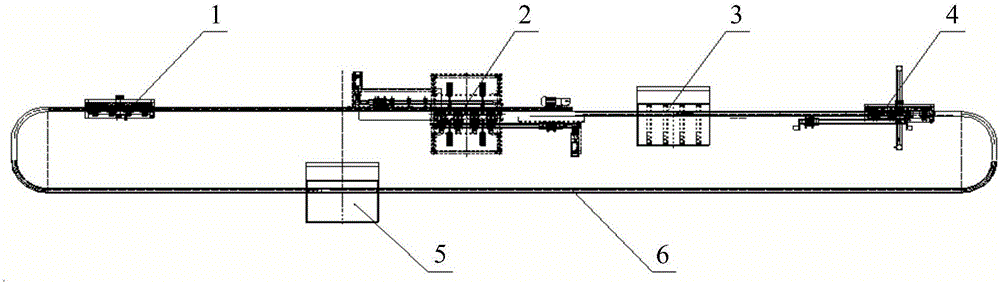

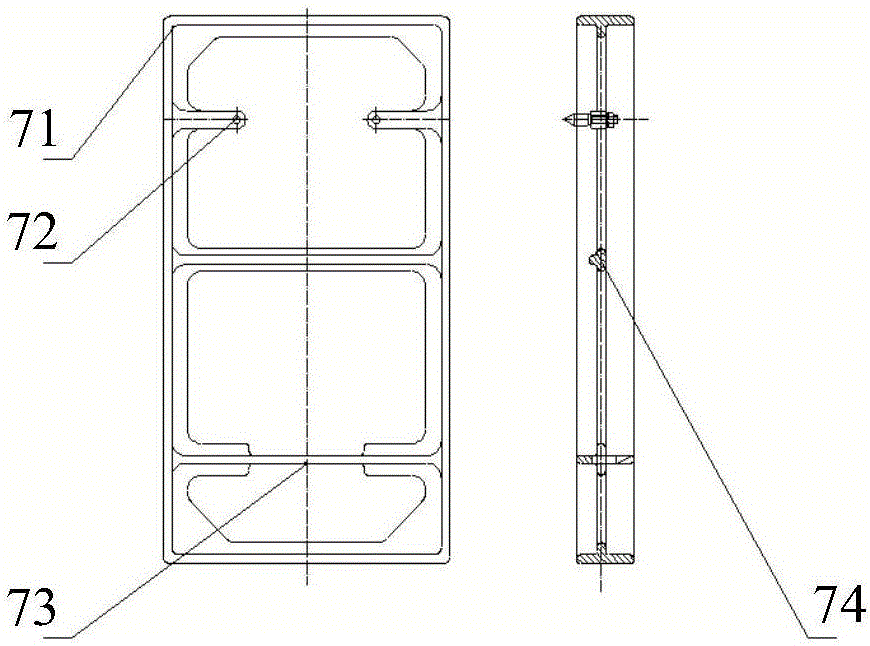

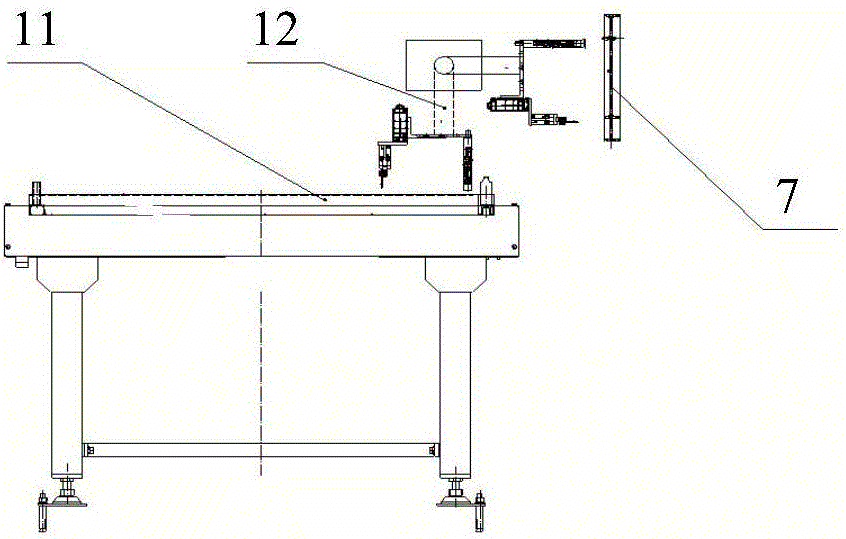

Medical glass slide transferring system and method based on machine vision

PendingCN110482219AAutomate the transferAvoid the risk of direct contactCharge manipulationConveyor partsMobile vehicleMachine vision

The invention discloses a medical glass slide transferring system and method based on a machine vision. The system involves a mechanical arm, a moving vehicle and a visual positioning module, whereinthe mechanical arm is arranged on the moving vehicle, the visual positioning module is in communication with the mechanical arm, the mechanical arm is in communication with the mobile vehicle, the mobile vehicle drives the mechanical arm to move to a first position, the visual positioning module is used for collecting the position information of a glass slide disc and transmitting the collected position information to the mechanical arm, and the mechanical arm realizes clamping of the glass slide disc according to the received position information. The system and the method have the beneficialeffects that the automatic transfer of the glass slide disc can be realized, the risk that the human body is exposed to the direct contact in the medical waste environment is avoided, the situationsthat the materials are polluted and the like are avoided.

Owner:QILU UNIV OF TECH +1

Empty bag circulating device

InactiveCN106742331AEasy to moveAutomate the transferPackage sterilisationPackaging automatic controlEngineeringMechanical engineering

The invention discloses an empty bag circulating device which comprises a circulating conveying line (6), a circulating clamp (7) mounted on the circulating conveying line (6) and capable of moving along the same, a clamp bag-feeding device (1) for mounting an empty bag (8) onto the circulating clamp (7) and a filling and sealing bag-feeding device (4) for mounting the empty bag (8) of the circulating clamp (7) onto a filling and sealing machine. The clamp bag-feeding device (1) and the filling and sealing bag-feeding device (4) are sequentially fixed around the circulating conveying line (6), the circulating conveying line (6), the inside thereof, the circulating clamp (7), the clamp bag-feeding device (1) and the filling and sealing bag-feeding device (4) are at a first-stage preset sterile grade, the outside of the circulating conveying line (6) is at a second-stage preset sterile grade, and the first-stage preset sterile grade is higher than the second-stage preset sterile grade. By the empty bag circulating device, sterile covneying of the empty bag is realized effectively.

Owner:SHINVA MEDICAL INSTR CO LTD

Automatic conveying mechanism for side plate of air conditioner

PendingCN105858065AAutomate the transferIncrease productivityConveyorsConveyor partsUltimate tensile strengthAutomatic processing

The invention provides an automatic conveying mechanism for a side plate of an air conditioner, belongs to the technical field of automatic processing, and solves the technical problems of low transferring and storing efficiency of an existing side plate of the air conditioner in the processing. According to the technical scheme, the mechanism comprises a conveying rack, a plurality of conveying shafts, a conveying belt and an adsorbing assembly, wherein the conveying rack consisting of an input section and an output section is axially arranged; the plurality of conveying shafts are connected to the conveying rack and transversely distributed on the input section; the conveying belt is positioned at the output section and connected to the conveying rack; a workpiece moves to the lower part of the conveying belt through the conveying shafts; the adsorbing assembly which is arranged at the output section transversely passes through the conveying belt and is connected to the conveying rack; the workpiece can move along with the conveying belt through the adsorbing assembly; when moving to the output section, the workpiece can fall down from the bottom part of the conveying rack. The mechanism has the beneficial effects that the workpiece can be automatically transferred through the conveying rack structure, so that the working intensity of workers can be reduced, and the overall production efficiency of the workpiece can be improved.

Owner:NINGBO XINYONGCHENG NUMERICAL CONTROL AUTOMATION EQUIP

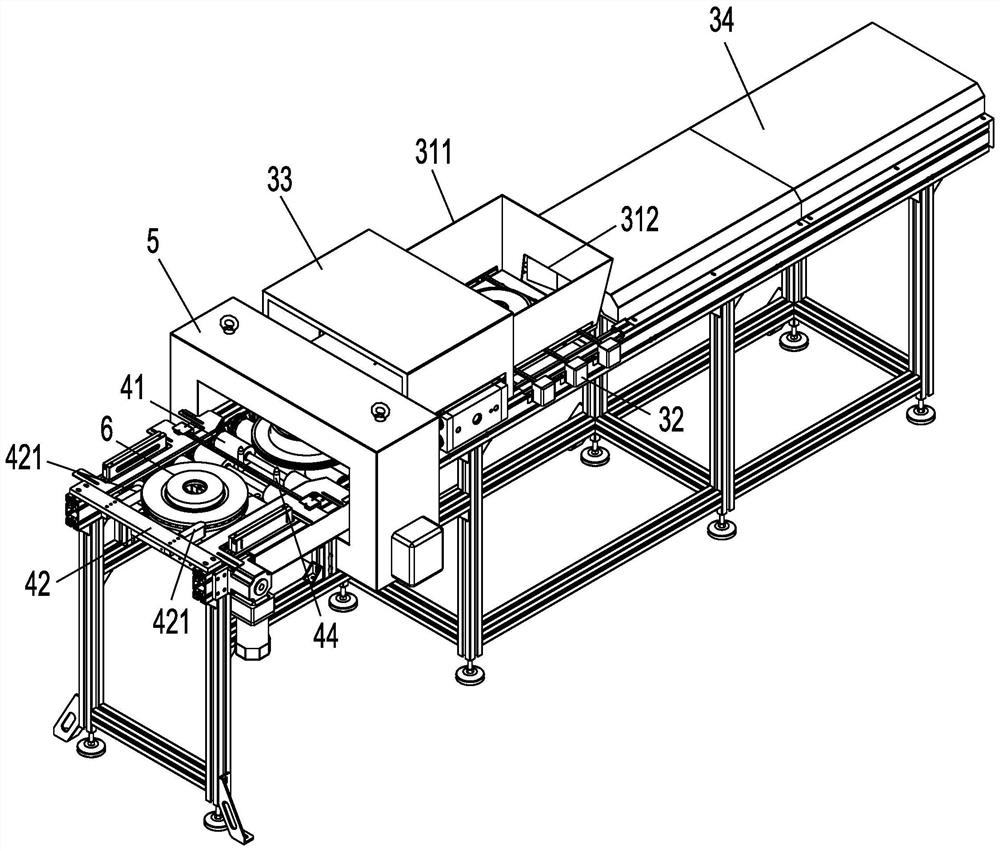

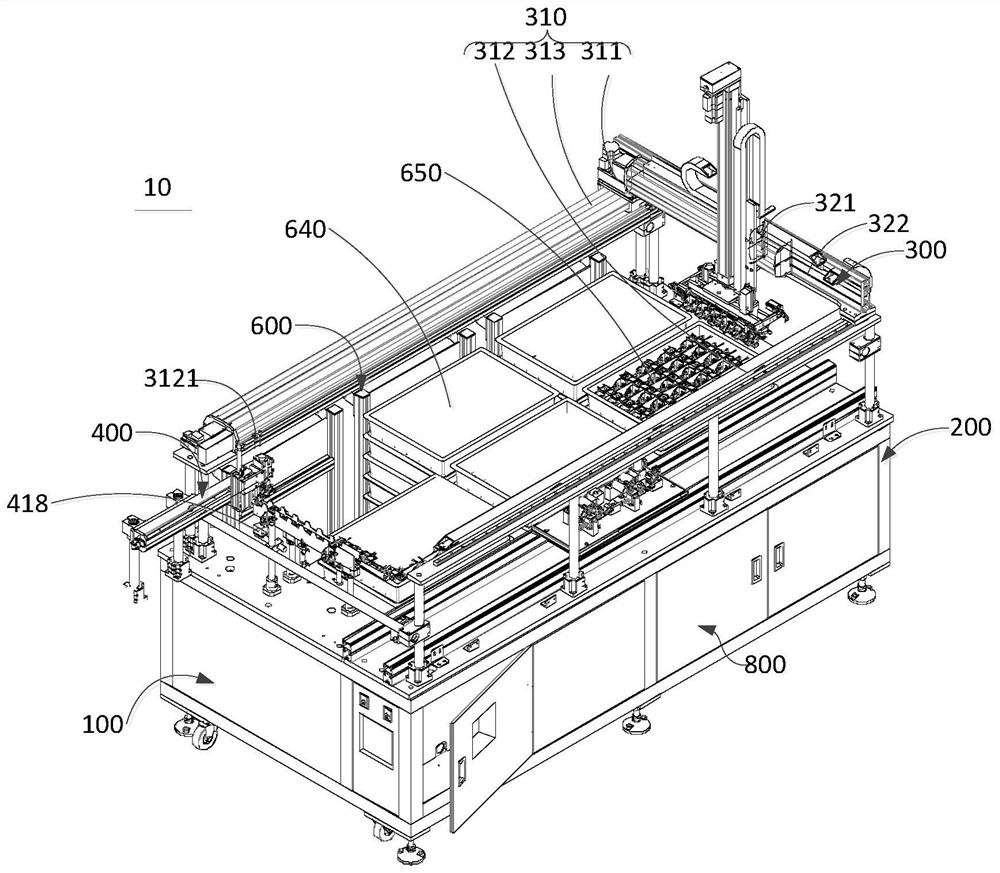

Bracket feeding machine and automatic feeding method thereof

PendingCN113023281AAutomate the transferImprove automationControl devices for conveyorsMechanical conveyorsTransfer mechanismReclaimer

The invention discloses a bracket feeding machine and an automatic feeding method thereof. The bracket feeding machine comprises a rack, a bracket fetching mechanism and a bracket transfer mechanism, wherein the bracket fetching mechanism and the bracket transfer mechanism are arranged on the rack; the rack comprises a containing space, and the containing space is used for containing and fixing a material trolley capable of entering and leaving; the material trolley can be used for containing a plurality of trays; the trays are used for placing brackets, and the bracket fetching mechanism can be moved back and forth above the containing space and the bracket transfer mechanism, can extend into the containing space to clamp the brackets and / or the trays and place the brackets on the bracket transfer mechanism and / or place the trays at a vacant area in the containing space; and the bracket transfer mechanism is used for transferring the brackets to the next station. Through the structure, rapid transfer of the brackets can be achieved, and therefore automation can be greatly improved; the efficiency is improved, and it can be guaranteed that the brackets can reach the next station according to the preset pose; and the yield of follow-up machining is effectively increased.

Owner:深圳市合利士智能装备有限公司

Building dustproof device

PendingCN114380082AAvoid pollutionAvoid automated transfersRefuse transferringLoading/unloadingArchitectural engineeringStructural engineering

The invention discloses a building dustproof device which comprises an annular isolation hood, a rotary shovel plate, a rotary driving assembly, elastic cloth, a sliding seat and an opening and closing assembly. The annular isolation cover is of a hollow structure, an inner hole is formed in the upper portion of the annular isolation cover, the lower portion of the annular isolation cover is of a through structure, an opening structure is arranged on the annular isolation cover, and the opening structure is communicated with the inner hole and a hollow inner cavity of the annular isolation cover; the rotary shovel plate is rotatably installed below the annular isolation cover, the rotary driving assembly is installed on the outer side face of the annular isolation cover, and the rotary driving assembly is connected with the rotary shovel plate; the rotary shovel plate is provided with a center hole opposite to the inner hole in position and a notch opposite to the opening structure in position, and a plurality of opening grooves are formed in the rotary shovel plate at intervals. The shielding mechanism plays a role in noise isolation and dust prevention, and noise pollution and dust pollution are avoided.

Owner:湖南金色畅联科技有限公司

A grain peeling device

ActiveCN114628303BGuaranteed stabilityEasy to peel offSolid-state devicesSemiconductor/solid-state device manufacturingWaferEngineering

A crystal grain peeling device belongs to the technical field of industrial automation and chip processing. Multiple placement trays. There is a rotating disc on the rotating jacking mechanism. There is a rectangular plate on the peeling mechanism, the rectangular plate is located directly above the rotating plate, a circular hole is formed on the rectangular plate, a peeling cylinder is installed on the upper side of the rectangular plate, and the movable end of the peeling cylinder is provided with a peeling arc plate, and the circular hole is located in the peeling arc. On the moving track of the plate, the rectangular plate is provided with a discharging member, and the discharging end of the discharging member is provided with a slag collecting member. By rotating the lifting mechanism, the placing plate, the peeling mechanism and the positioning mechanism, the invention conveniently, automatically and efficiently completes the peeling operation of the crystal grains after the wafer is split, thereby reducing the operator's participation in the operation process and improving the crystallinity. The degree of automation in pellet peeling.

Owner:四川上特科技有限公司

Processing method and processing device of novel high-efficiency polycrystalline four-resistance gate cell sheet

ActiveCN105161400AAutomate the transferBlow dry to achieveFinal product manufactureSemiconductor/solid-state device manufacturingState of artLifting gas

The invention provides a processing method and a processing device of a novel high-efficiency polycrystalline four-resistance gate cell sheet, and belongs to the electronic technical field. The processing method and the processing device solve the problem that methods and devices in the prior art fail to automatically and effectively process the novel high-efficiency polycrystalline four-resistance gate cell sheet. The processing device of the novel high-efficiency polycrystalline four-resistance gate cell sheet comprises a machine frame. The machine frame is fixedly provided with a first processing container, a second processing container and a third processing container. The first processing container is provided with a first processing cylinder. The first processing cylinder is provided with a first lifting plate. The machine frame fixes a guide rail. The guide rail is provided with a sliding block. The sliding block is provided with a lifting gas cylinder. The lifting gas cylinder is fixedly provided with a take and put manipulator. The sliding block is connected with a moving mechanism. The moving mechanism comprises a nut, a lead screw, a motor and a bearing. The second processing container is internally provided with a stirring device. The third processing container is provided with a jet pipe I and a jet pipe II. By the processing method and the processing device, the cell sheet is effectively processed, and the processing efficiency is high.

Owner:浙江德西瑞无纺科技有限公司

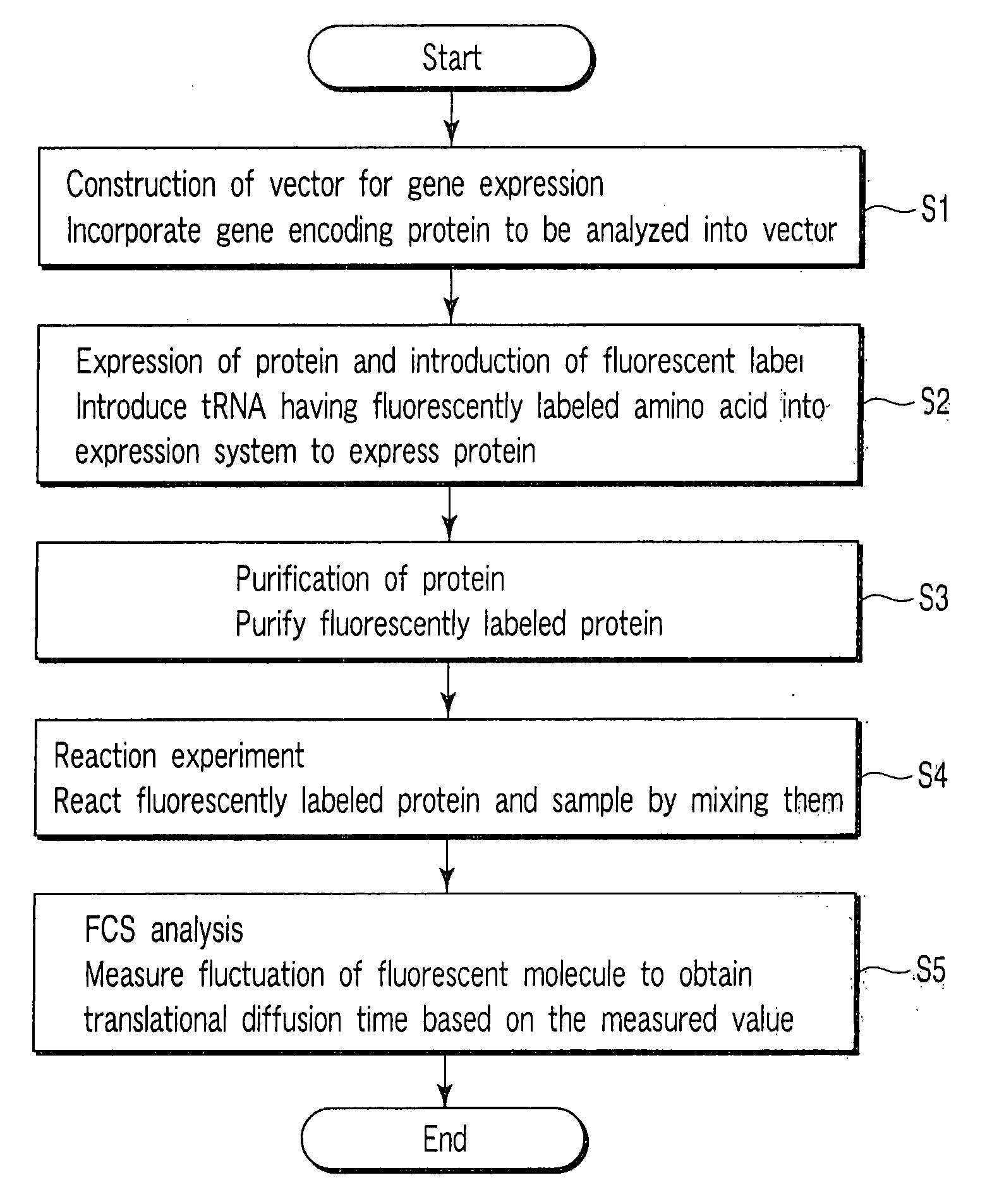

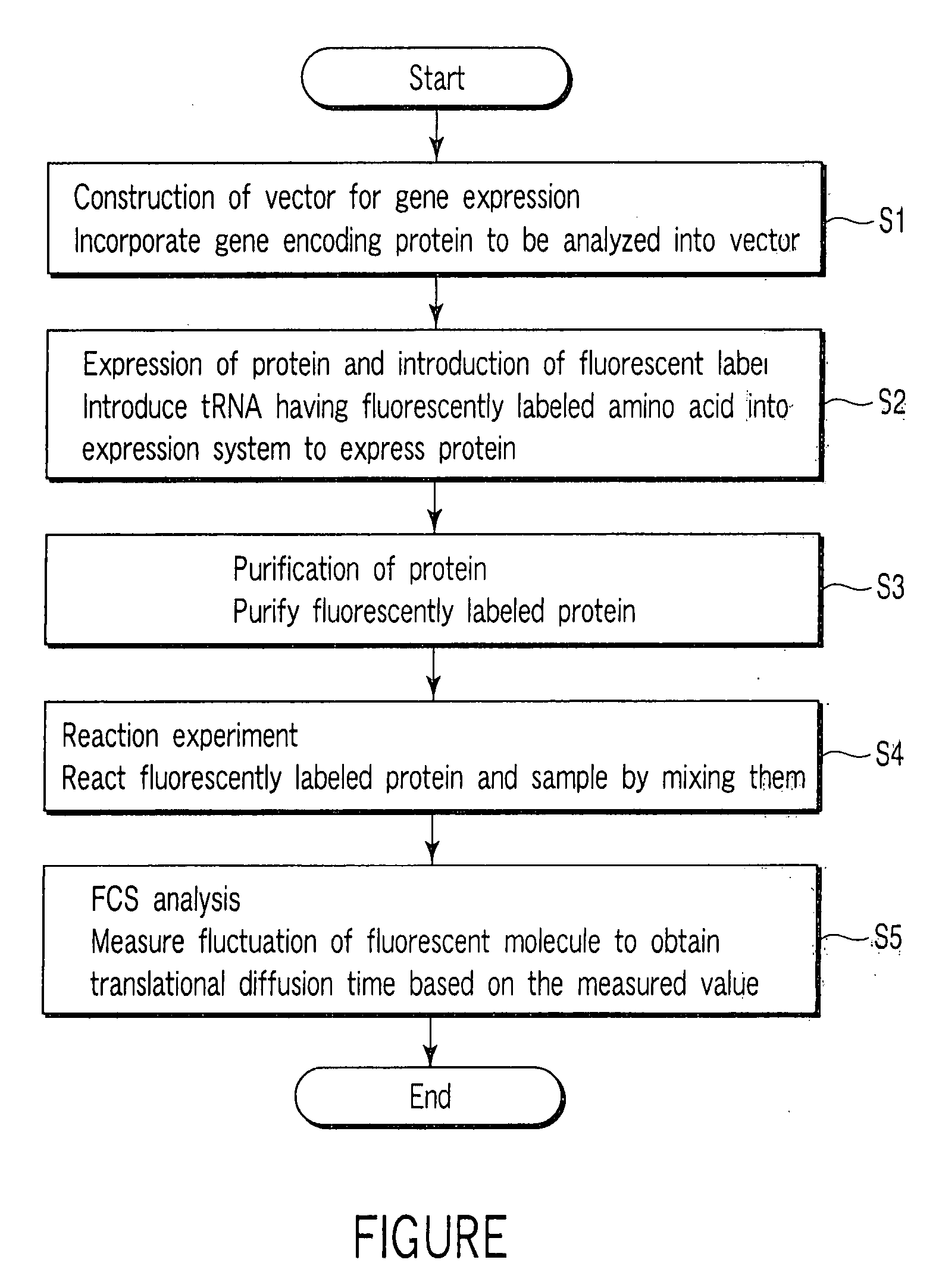

Method for detecting reaction of protein and sample

InactiveUS20080038747A1High precisionPromotion and inhibition of and absence of influenceMicrobiological testing/measurementMaterial analysisGene expressionAmino acid

There is provided a method for detecting a reaction of a fluorescently labeled protein and a sample simply, in a short time and at a higher precision. By using an expression system such as an extracellular gene expression system and an extracellular transcription or translation system, a reaction of expressing a protein from a constructed vector is performed. At this time, a fluorescently labeled amino acid is introduced into the expression system in the form of a tRNA having the fluorescently labeled amino acid. With expression of a protein, the fluorescently labeled amino acid is incorporated into the protein, and a fluorescently labeled protein (hereafter, referred to as fluorescently labeled protein) is produced. The fluorescently labeled protein and a sample S are mixed to prepare a mixed solution, and FCS measurement is performed. Based on a measured value of the FCS, the presence or absence of a reaction is detected.

Owner:OLYMPUS CORP

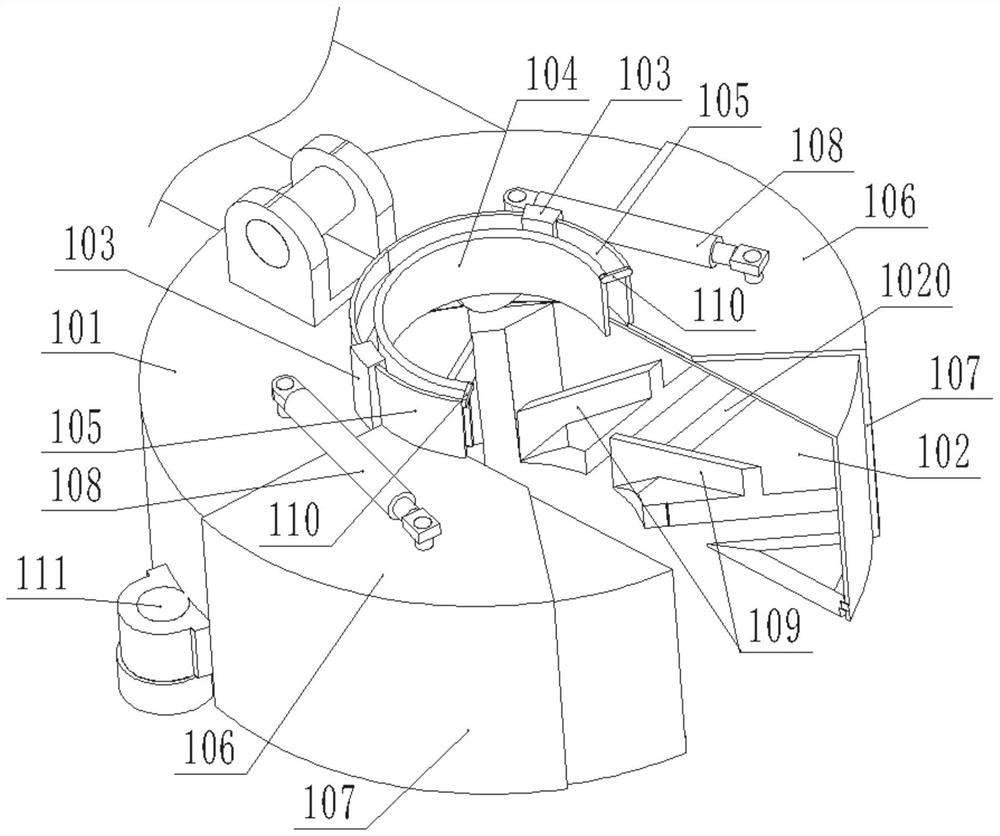

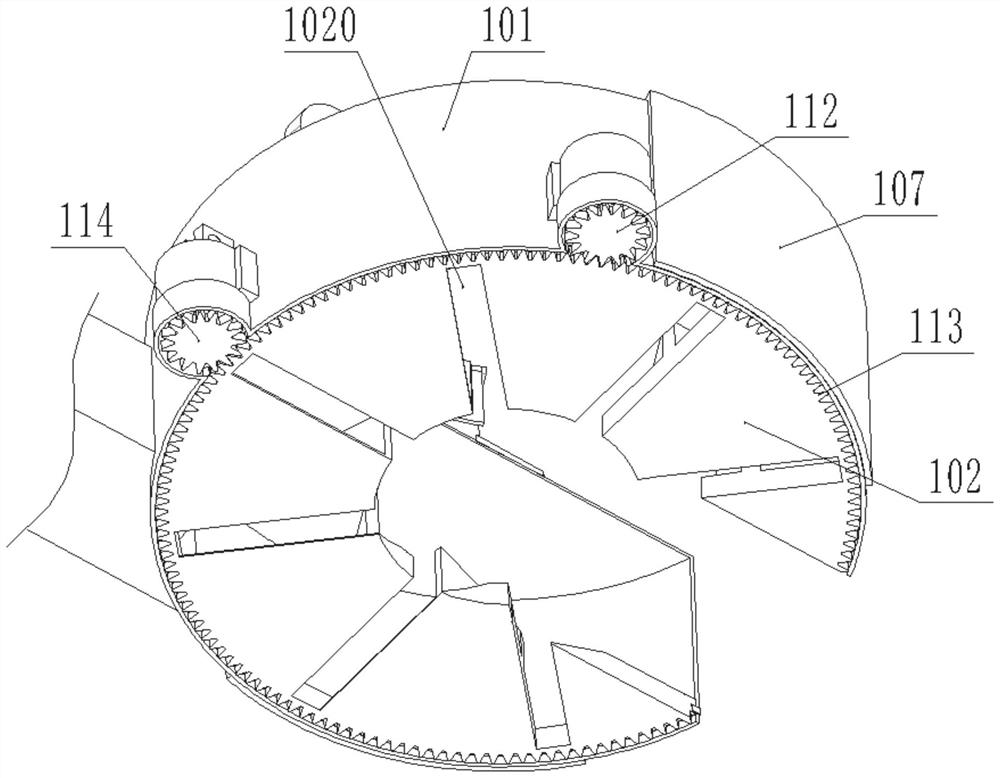

A self-pairing intelligent assembly robot and assembly method for electric fasteners

ActiveCN111421332BAutomate the transferRealize regulationAssembly machinesMetal working apparatusRobot handControl engineering

The invention discloses an electric fastener self-pairing type intelligent assembling robot and an assembling method. A robot body is included. Two components forming a fastener are subjected to transferring and direction adjustment through pairing bases assembled to the components. The components can disengage from the pairing bases under the action of external force. Each of the two sides of therobot body is provided with a mechanical arm for transferring the corresponding pairing base loading the component, a transfer pairing mechanism for conducting direction adjustment on the corresponding pairing base loading the component, and an automatic assembling mechanism for assembling the component obtained after direction adjustment. The fastener assembling method comprises the steps that the mechanical arms and the transfer pairing mechanisms are sequentially used for conducting conveying and direction adjustment on the pairing bases loading the components, the automatic assembling mechanisms are used for assembling the two components, and the purpose of automatic assembling of fasteners with complex appearances is achieved.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

Processing method and processing device for polycrystalline four-resistance grid cells

ActiveCN105161400BAutomate the transferEasy to cleanFinal product manufactureSemiconductor/solid-state device manufacturingGrid cellManipulator

The invention provides a processing method and a processing device of a novel high-efficiency polycrystalline four-resistance gate cell sheet, and belongs to the electronic technical field. The processing method and the processing device solve the problem that methods and devices in the prior art fail to automatically and effectively process the novel high-efficiency polycrystalline four-resistance gate cell sheet. The processing device of the novel high-efficiency polycrystalline four-resistance gate cell sheet comprises a machine frame. The machine frame is fixedly provided with a first processing container, a second processing container and a third processing container. The first processing container is provided with a first processing cylinder. The first processing cylinder is provided with a first lifting plate. The machine frame fixes a guide rail. The guide rail is provided with a sliding block. The sliding block is provided with a lifting gas cylinder. The lifting gas cylinder is fixedly provided with a take and put manipulator. The sliding block is connected with a moving mechanism. The moving mechanism comprises a nut, a lead screw, a motor and a bearing. The second processing container is internally provided with a stirring device. The third processing container is provided with a jet pipe I and a jet pipe II. By the processing method and the processing device, the cell sheet is effectively processed, and the processing efficiency is high.

Owner:浙江德西瑞无纺科技有限公司

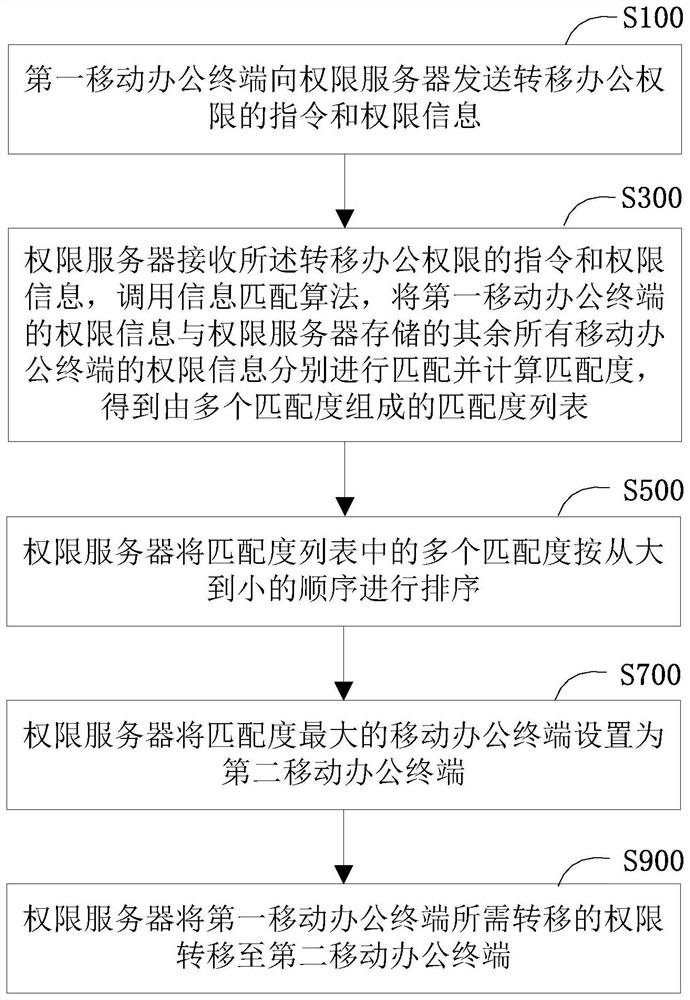

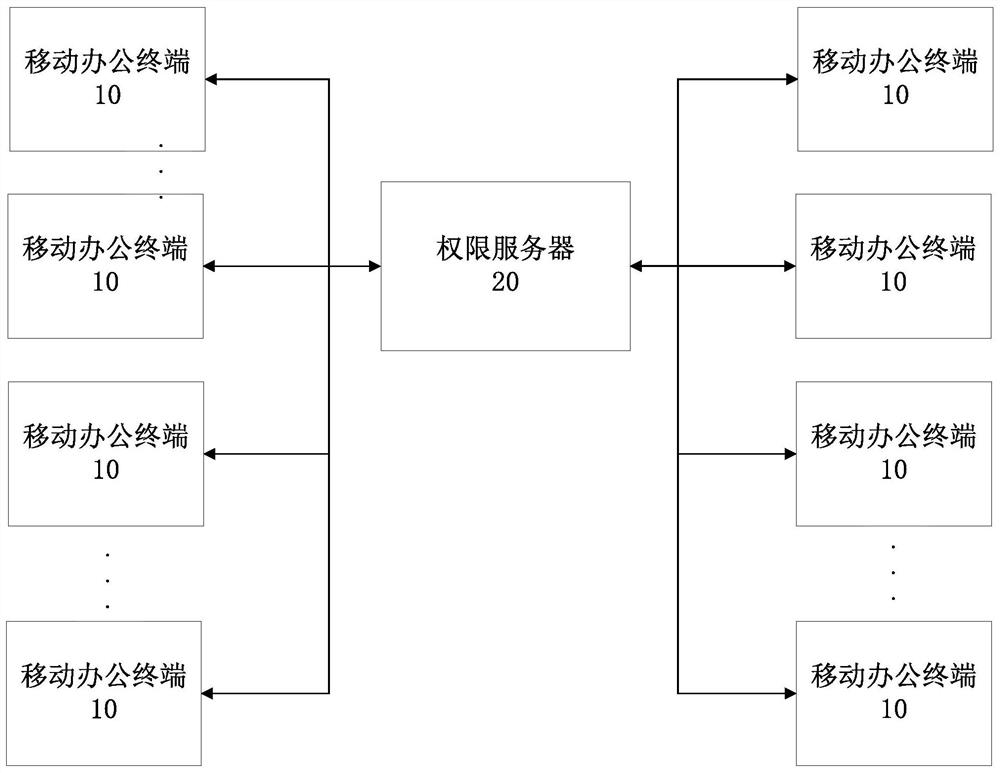

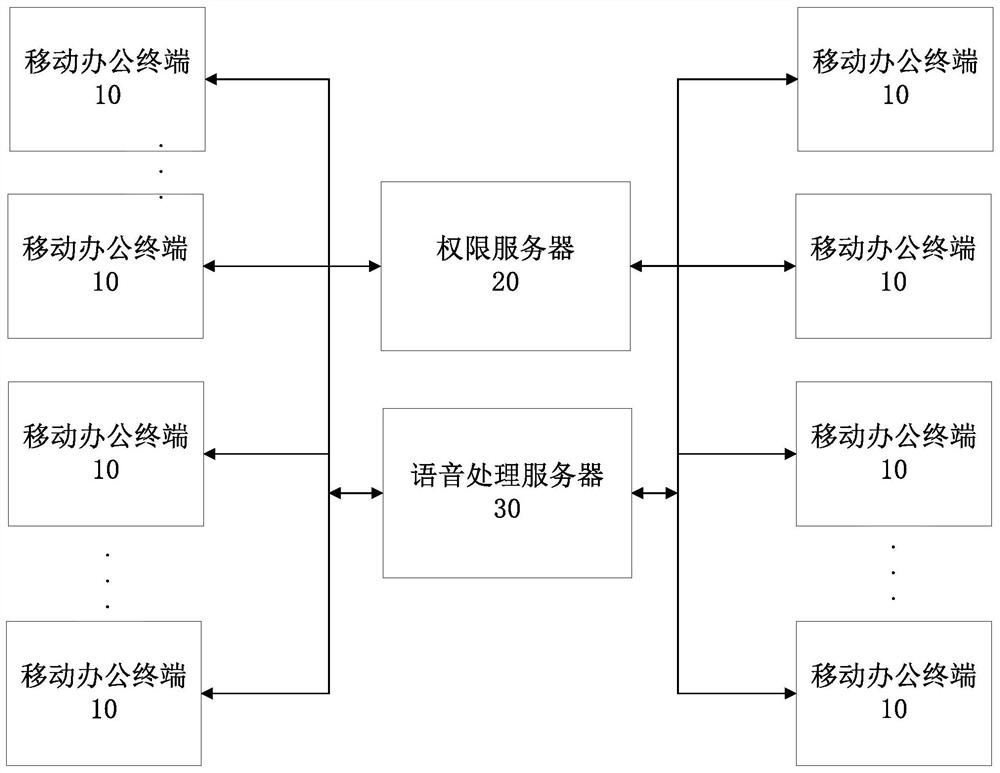

Method for automatically transferring office authority and mobile office system

PendingCN112818324AAutomate the transferHigh degree of authority matchingCharacter and pattern recognitionDigital data authenticationInternet privacyEngineering

The invention discloses a method for automatically transferring office authority, which comprises the following steps of: receiving an instruction for transferring office authority and authority information of a first mobile office terminal by an authority server; if yes, the permission server sets a specified permission receiving terminal as a second mobile office terminal, the permission server transfers the permission needing to be transferred by the first mobile office terminal to the second mobile office terminal, and operation is ended; otherwise, calling an information matching algorithm, respectively matching the authority information of the first mobile office terminal with the authority information of all other mobile office terminals stored in the authority server, and calculating matching degrees to obtain a matching degree list comprising a plurality of matching degrees; the authority server sets the mobile office terminal with the maximum matching degree as a second mobile office terminal; and the authority server transfers the office authority required to be transferred by the first mobile office terminal to the second mobile office terminal.

Owner:CHINA TOBACCO ZHEJIANG IND

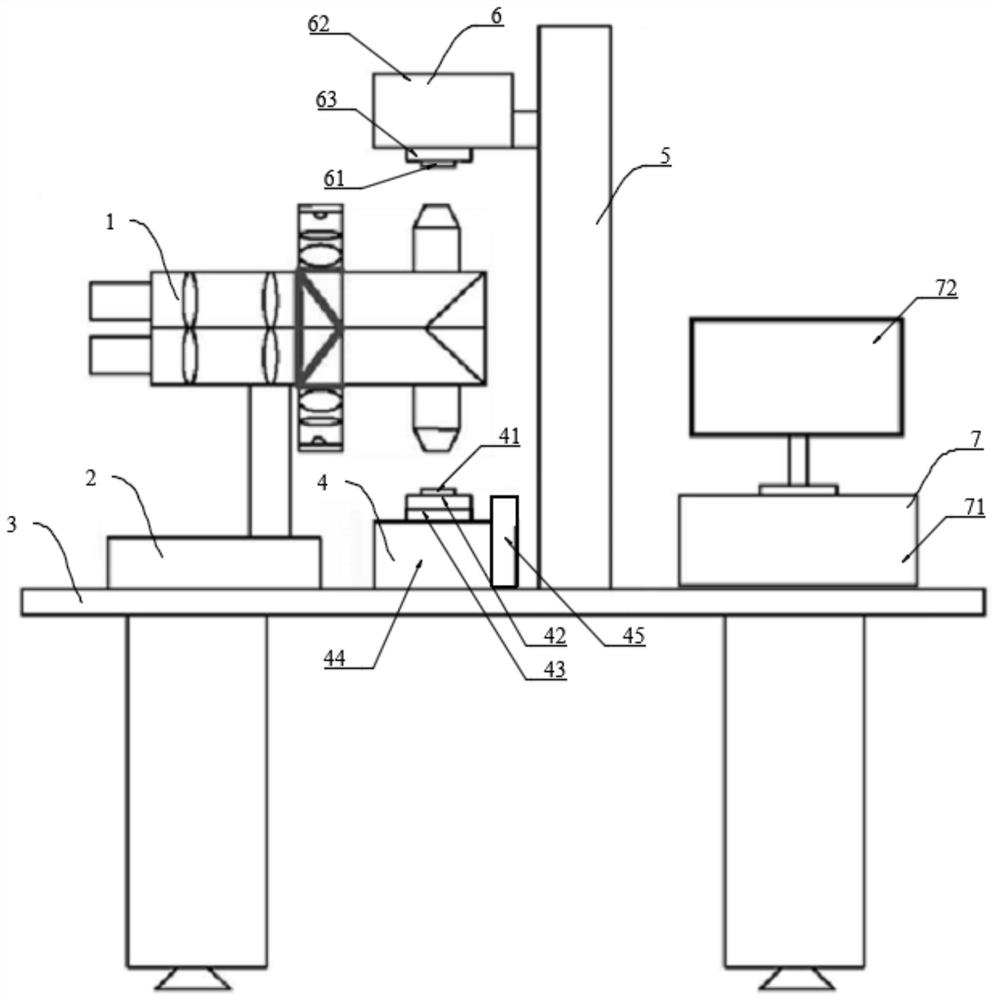

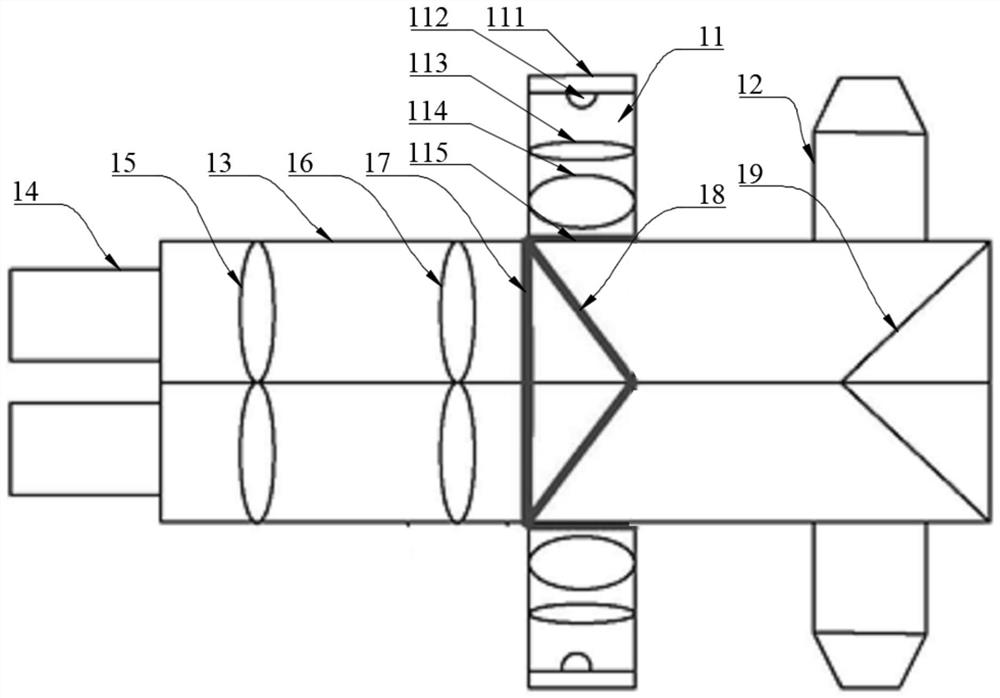

Composite fluorescence microscopy system for nano material transfer

PendingCN111624758ASolve the problem of low transfer accuracyHigh transfer accuracyMicroscopesFluorescenceMaterial transfer

The invention discloses a composite fluorescence microscopy system for nano material transfer. The composite fluorescence microscopy system comprises an optical microscopy imaging device, a numericalcontrol horizontal moving platform, a damping platform, a target substrate control device, a Z-axis numerical control lifting device, a transfer substrate control device and a control device. The structure of the optical microscope imaging device is optimally designed, and an optical microscopic imaging technology and an automation technology are integrated so that the problem of low two-dimensional material transfer precision in the field of nano material research is solved; according to the composite fluorescence microscopic system for nano material transfer, the transfer precision of the two-dimensional material can be improved, the automatic transfer of the two-dimensional material is realized, the transfer operation of the two-dimensional material is simplified, and the selection limitation of a substrate material during the preparation of the two-dimensional material is broken.

Owner:广州浩康生物科技有限公司

Bread transporting system

InactiveCN107953402AAutomate the transferFull range of flexible movementMetal working apparatusEngineeringTransmission belt

The invention discloses a bread transporting system, and a forward transmission belt pushing device, a middle bread cutting transporting machine and a rear mechanical handling arm device are cooperatively connected to form a bread processing transporting system; the transmission belt pushing device is used for blocking breads at the connecting position of the transmission belt pushing device and the bread cutting transporting machine, the breads are laterally pushed away from the transmission belt pushing device through a first transmission belt and are transported to a second transmission belt which is perpendicular to the first transmission belt of the bread cutting transmission belt to achieve the bread automatic transferring of two mutually perpendicular transmission belts, and furtherthe breads enter the bread cutting transporting system to be cut and are transported to the mechanical handling arm device through the transmission belt pushing device; and the flexible movement of the mechanical handling arm device in all directions can be realized through the up-down movement of a connecting rod mechanism of the mechanical handling arm device and the rotating movement of a third actuator, the breads can be transported to processing machines of all directions of the mechanical handling arm device, the work efficiency and the health and the safety conditions can be improved,and the labor cost in the productive process can be effectively reduced.

Owner:江门市神川自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com