Automatic glass tank production device

An automatic production, glass jar technology, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve problems such as affecting the efficiency of glass jar transfer work, arm soreness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

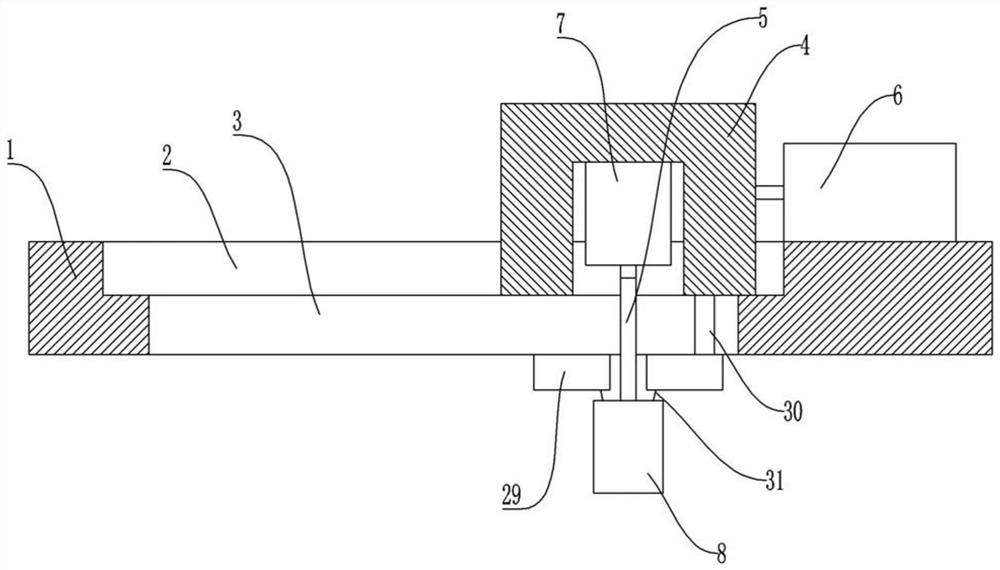

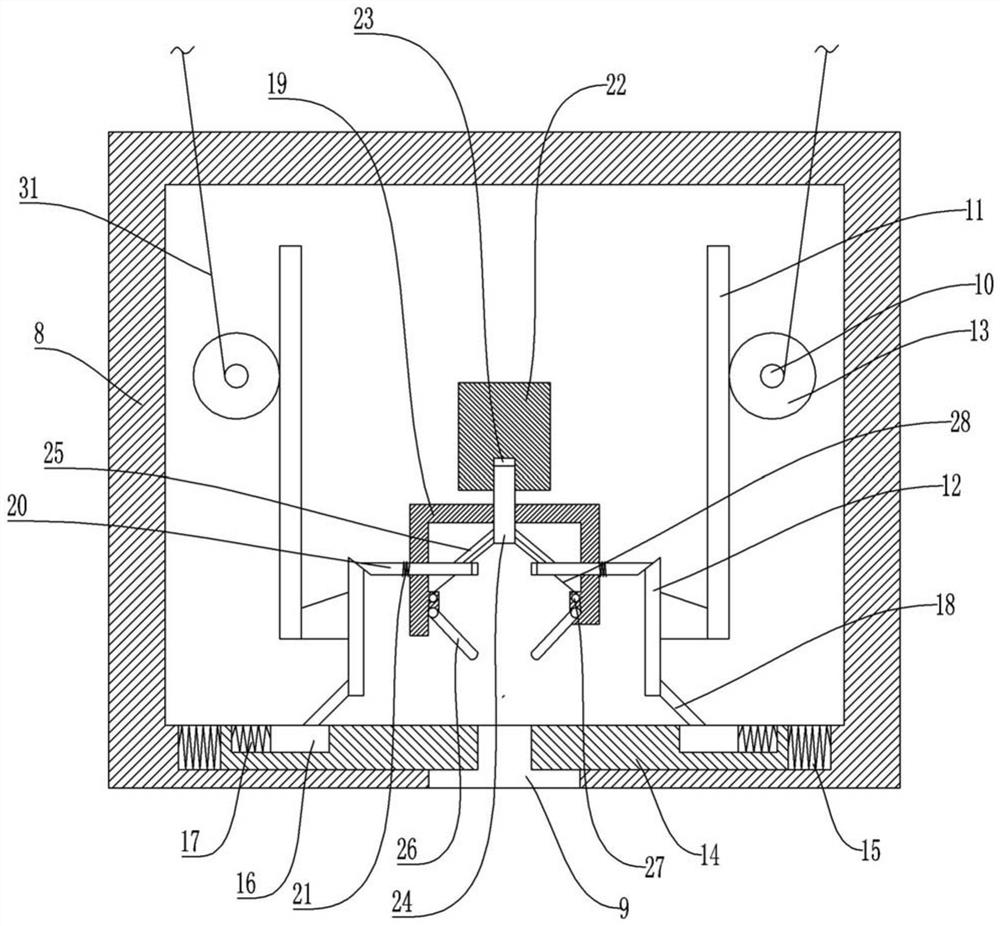

[0026] Basic as attached figure 1 And attached figure 2 Shown: the automatic production device for glass jars, including a machine base, on which a fixed plate 1 is fixed, and a horizontal groove 2 is opened on the fixed plate 1, and a horizontal block 4 is slidably connected to the horizontal groove 2; the bottom of the horizontal groove 2 A horizontal hole 3 is opened, and a movable rod 5 is fitted in the gap of the horizontal hole 3; it also includes a first power part for driving the horizontal block 4 to move laterally and a second power part for driving the movable rod 5 to move vertically; In the embodiment, the first power part is the first cylinder 6, the first cylinder 6 is affixed to the fixed plate 1, the output shaft of the first cylinder 6 is affixed to the transverse block 4; the second power part is the second cylinder 7, The second air cylinder 7 is affixed on the transverse block 4, and the output shaft of the second air cylinder 7 is affixed to the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com