Bread transporting system

A conveying system and bread technology, applied in metal processing, etc., can solve the problems of difficulty in realizing full automation, large movement resistance, and low degree of automation, and achieve the effect of improving production efficiency, sanitation and safety conditions, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

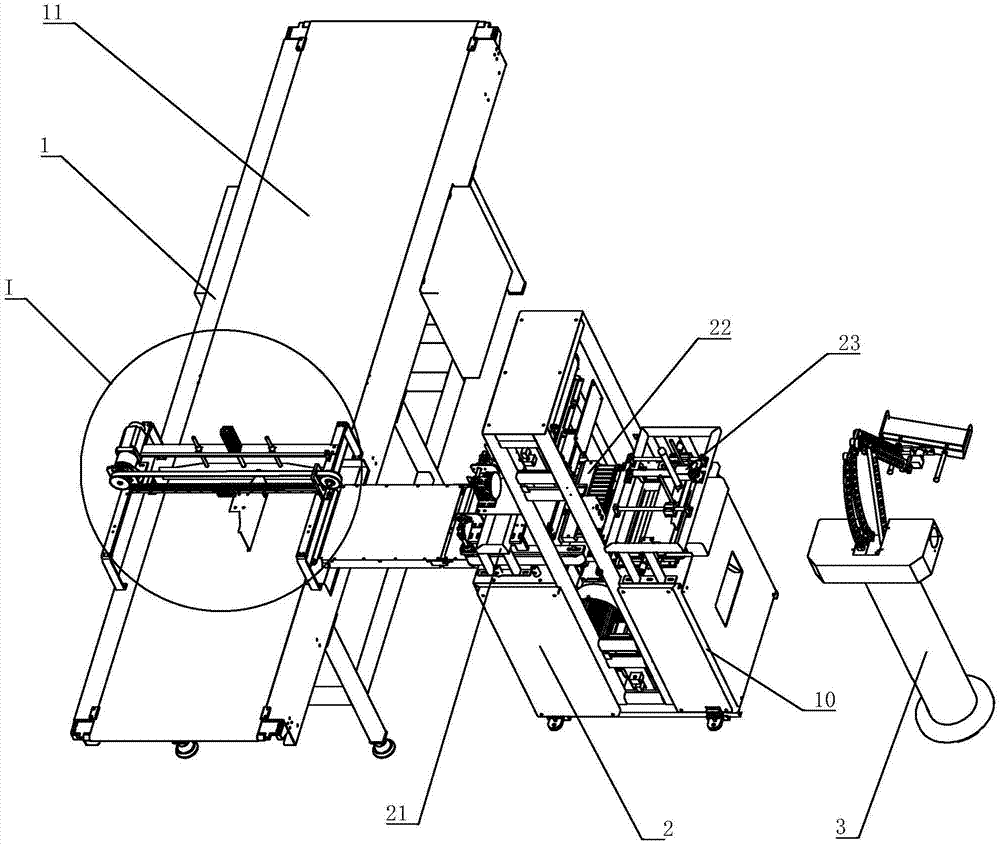

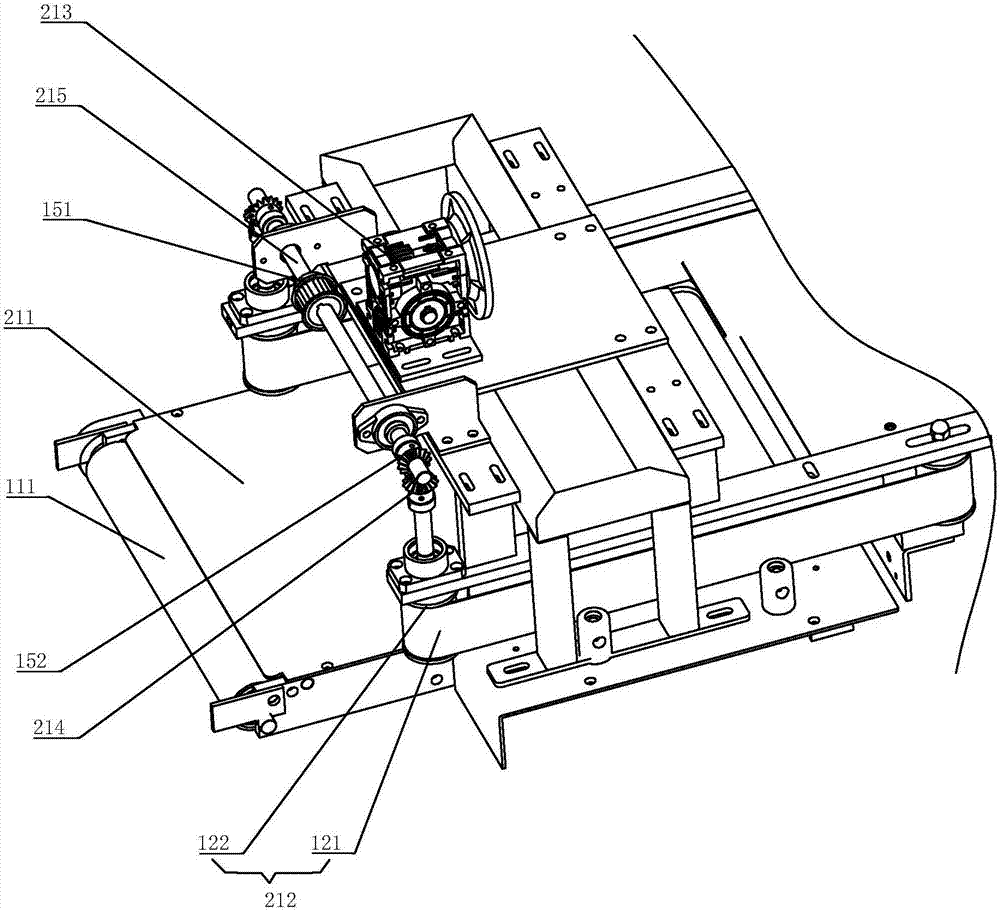

[0026] refer to Figure 1 to Figure 6 , a kind of bread conveying system of the present invention, comprises the conveyor belt pushing device 1 in front, the bread cutting conveyor 2 in the middle and the mechanical handling hand device 3 that is arranged on the bread cutting conveyor 2 rear, described conveyor belt pushing device 1 will The entire long strip of bread changes its direction of movement and is vertically transported into the bread cutting conveyor 2. After the preliminary cutting of the bread is completed, the bread cutting conveyor 2 transports the bread to the rear, and the mechanical handling device 3 handles it to carry it to the next processing mechanism. The entire bread processing conveying system;

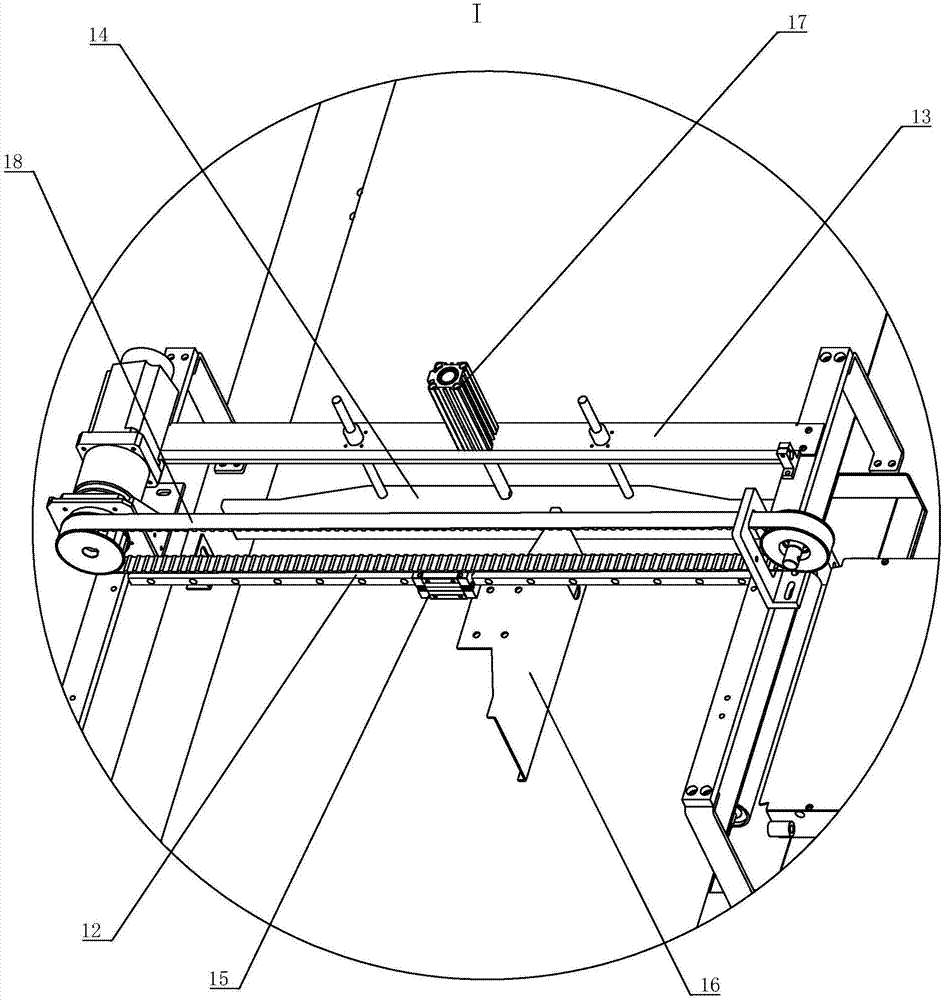

[0027] Described transmission belt pushing device 1 comprises the first transmission belt 11 and the support that is arranged on the first transmission belt 11 both sides, is installed with the first transmission belt 11 successively between the support on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com