PCR chip tray transfer and storage mechanism

A pallet transfer and chip technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of large storage space, low degree of automation, inconvenient automatic storage, etc., to improve work efficiency and reduce space. , to achieve the effect of automatic transfer and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

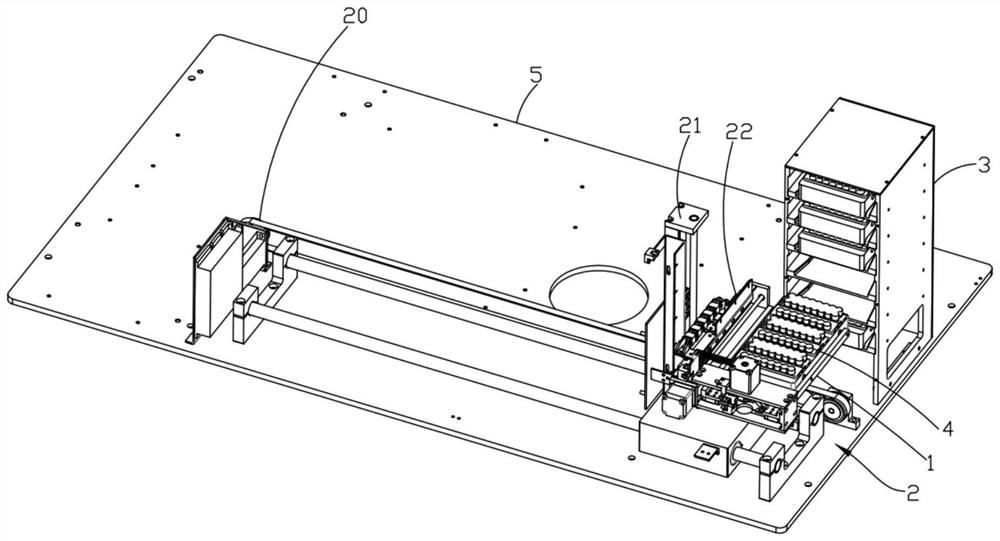

[0047] Such as Figure 1-4 As shown, a PCR chip tray transfer and storage mechanism in this embodiment includes: a mechanical gripper 1 for grabbing the chip tray 4, a three-dimensional drive mechanism 2 for driving the movement of the mechanical gripper 1, and a storage chip Storage bin 3 for pallet 4;

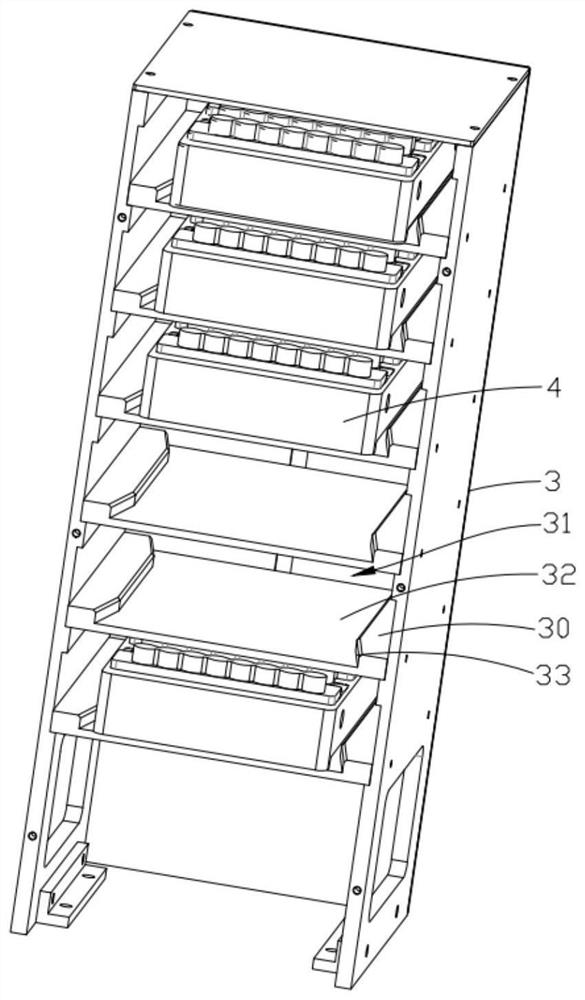

[0048] In the storage bin 3, several partitions 30 are used to separate and form several storage chambers 31 for storing chip trays 4 along the vertical direction;

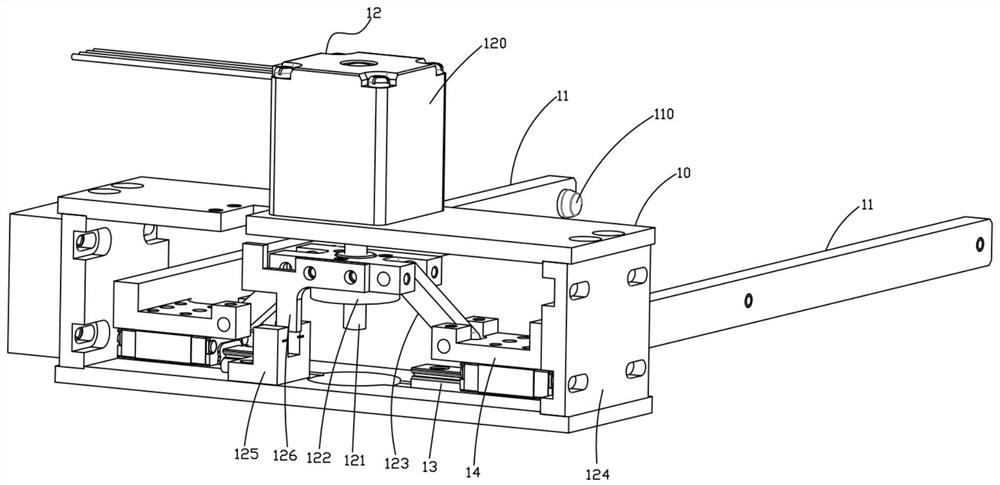

[0049] The mechanical gripper 1 includes a mounting base 10, two clamping rods 11 that can be slidably arranged on the mounting base 10 along the Y direction, and a jaw driving mechanism for driving the two clamping rods 11 to move along the Y direction to open or clamp 12. The three-dimensional driving mechanism 2 can drive the mechanical gripper 1 to move along the X direction to send the chip tray 4 on the mechanical gripper 1 into the storage chamber 31 . The mounting base 10 is provided with a jaw slide ra...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is only the jaw driving mechanism 12, refer to Figure 5-6 ,, In this embodiment, the jaw driving mechanism 12 includes a jaw motor 150 arranged on the mounting base 10, a cam 151 drivingly connected to the output shaft of the jaw motor 150, connected to the jaw slider 14 and positioned on the cam The friction wheel 152 on the side of 151 and the return spring 153 connected between the jaw slider 14 and the mounting seat 10;

[0057] The jaw motor 150 drives the cam 151 to rotate, and the friction wheel 152 is driven by the cam 151 to make the two jaw sliders 14 slide toward the side away from the cam 151 along the Y direction, driving the two clamping rods 11 to open; the two return springs 153 The two clamping jaw sliders 14 are set to generate an active force toward the cam 151, so that the clamping jaw sliders 14 slide back toward the direction of the cam 151 through the return spring 153, so as to realize the ...

Embodiment 3

[0060] refer to Figure 7-10 , as a further improvement on the basis of Embodiment 1 or 2, in this embodiment, the PCR chip tray transfer and storage mechanism also includes a base plate 5, and the three-dimensional drive mechanism 2 includes a Y-direction drive mechanism 20 arranged on the base plate 5, arranged on The Z-direction driving mechanism 21 on the Y-direction driving mechanism 20 and the X-direction driving mechanism 22 arranged on the Z-direction driving mechanism 21 , and the mechanical gripper 1 is arranged on the X-direction driving mechanism 22 .

[0061] Wherein, the Y-direction driving mechanism 20 includes a guide rod 200 arranged on the base plate 5 along the Y direction, a Y slider 201 slidably arranged on the guide rod 200, a Y motor 202 arranged on the base plate 5, and a connection between the Y motor 202 The Y driving pulley 203 drivingly connected to the output shaft, the Y driven pulley 205 drivingly connecting with the Y driving pulley 203 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com