Vertical conveying system for bread processing

A transmission system and bread technology, applied in metal processing, transportation and packaging, conveyor objects, etc., can solve the problems of difficult to achieve full automation, large movement resistance, low degree of automation, etc., to improve production efficiency and hygienic safety conditions , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

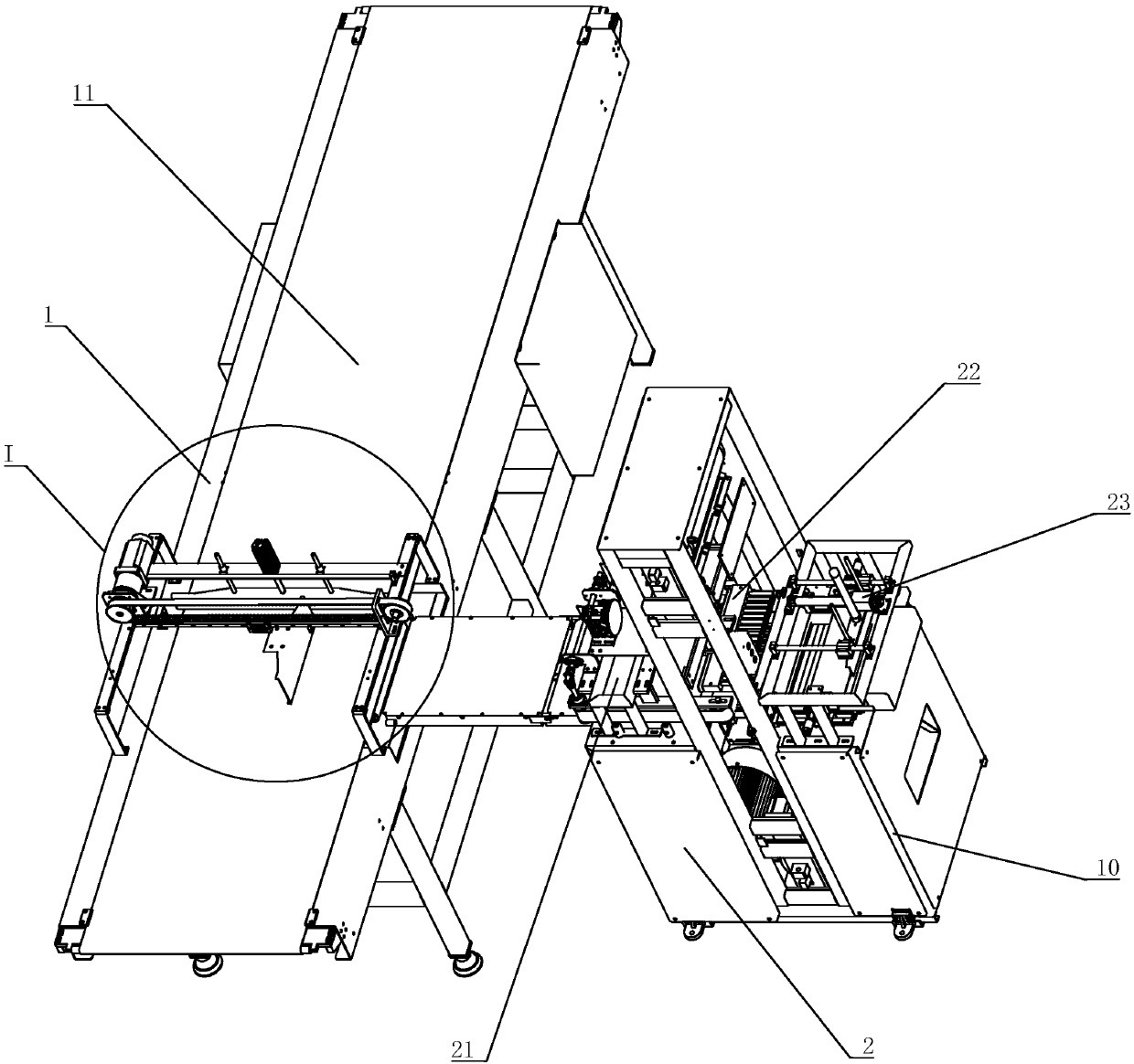

[0023] Reference Figure 1 to Figure 5 , The bread processing vertical conveying system of the present invention includes a front conveying belt pushing device 1 and a rear bread cutting conveyor 2. The conveying belt pushing device 1 transfers the entire long bread into the bread cutting conveyor by changing the direction of movement In 2, the bread cutting conveyor 2 is transported to the next processing mechanism.

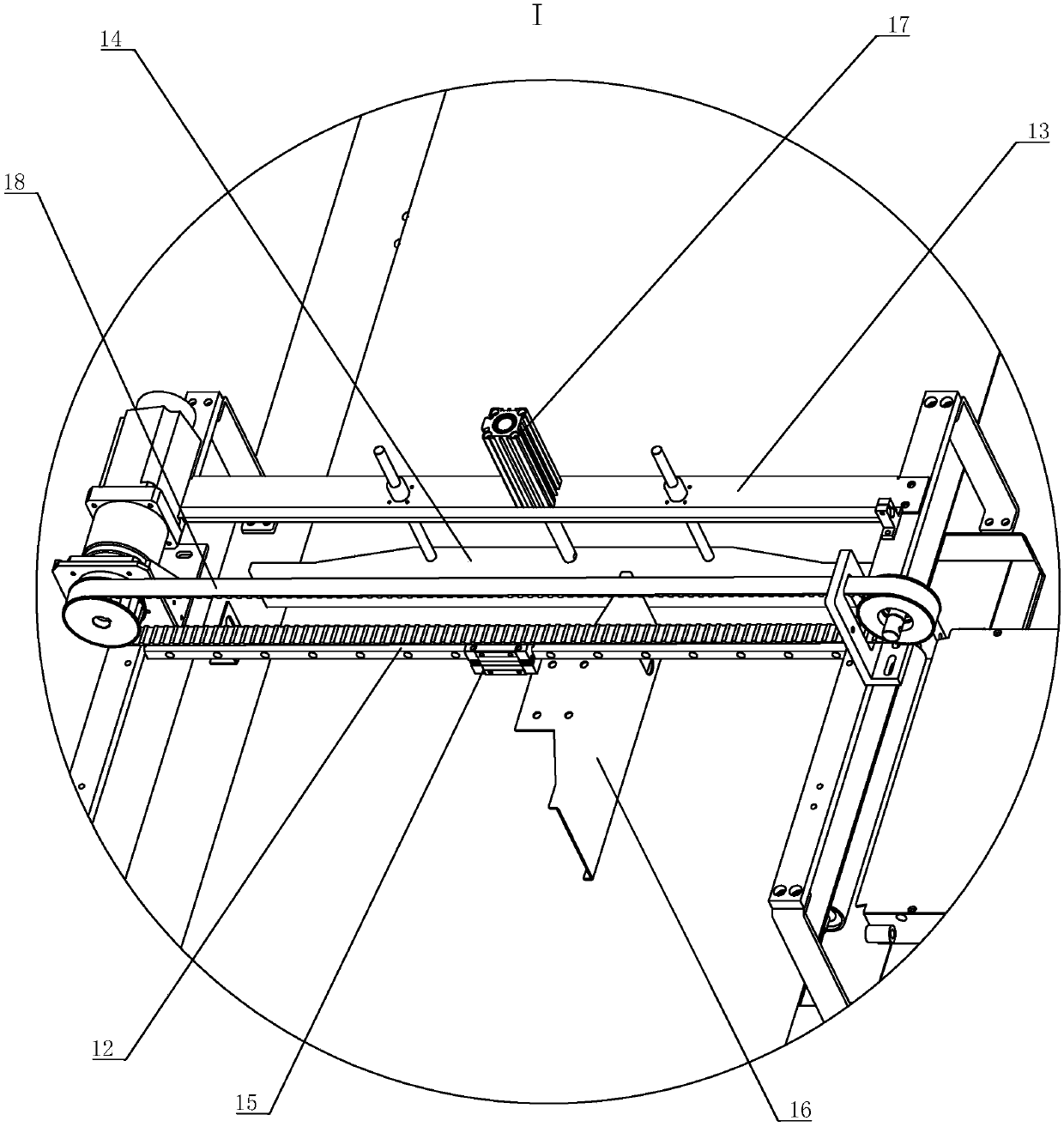

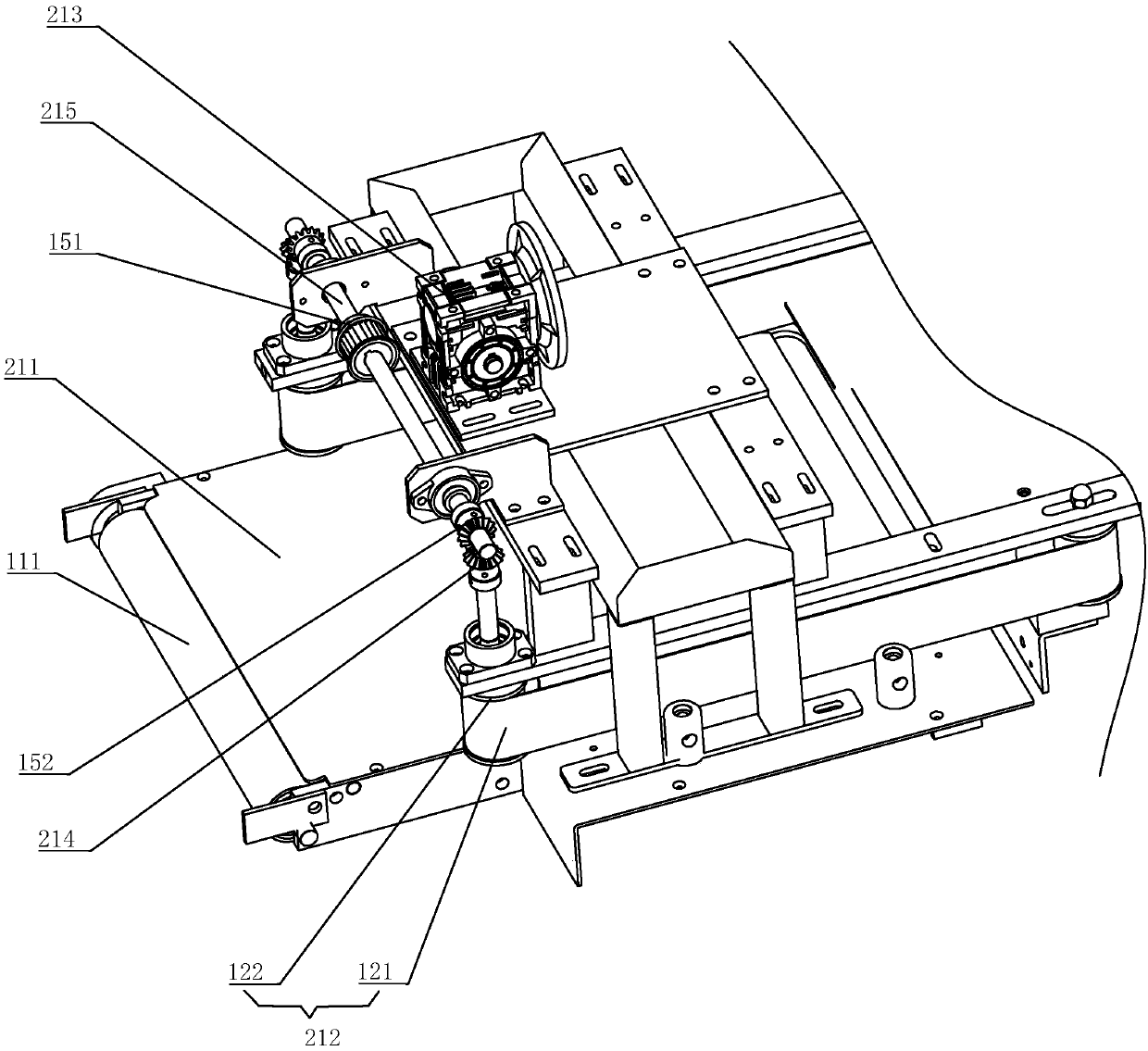

[0024] The conveyor belt pushing device 1 includes a first conveyor belt 11 and brackets arranged on both sides of the first conveyor belt 11. Between the brackets on both sides along the transmission direction of the first conveyor belt 11 are sequentially installed with the first conveyor belt 11 A vertical slide rail 12 and a baffle mounting member 13 are fitted with a slider 15 on the slide rail 12, a driving device is arranged inside the slider 15 and a vertical push plate 16 is installed at the lower end, of course, the slider 15 It can be driven by an exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com