A grain peeling device

A technology for stripping device and grain, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the process of grain processing, reducing the quality of grain, and harming operators, so as to reduce the process, improve the safety, The effect of reducing stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

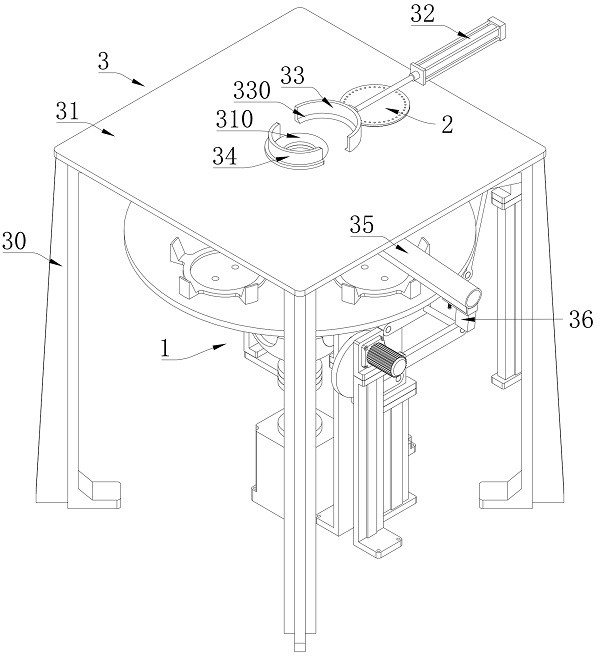

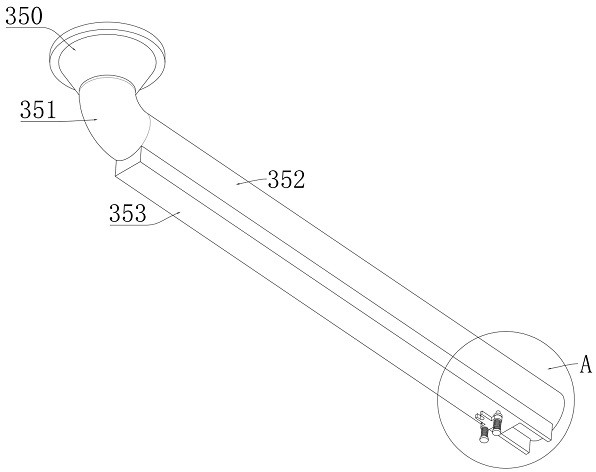

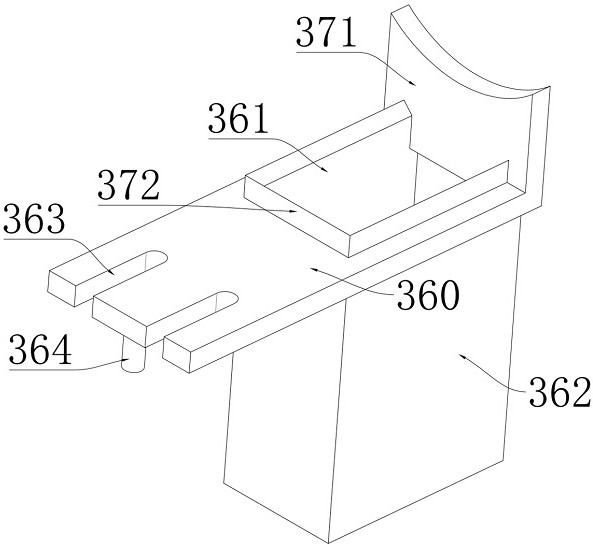

[0027] refer to figure 1 , Figure 5 , Figure 9 As shown, a grain peeling device includes a rotating jacking mechanism 1, a peeling mechanism 3 is arranged directly above the rotating jacking mechanism 1, a positioning mechanism 4 is arranged on the peeling mechanism 3, and a plurality of multiple jacks are arranged on the rotating jacking mechanism 1. Place tray 2. The rotary jacking mechanism 1 is provided with a rotary disk 111 . The stripping mechanism 3 is provided with a rectangular plate 31, the rectangular plate 31 is located directly above the rotating disk 111, the rectangular plate 31 is provided with a circular hole, a stripping cylinder 32 is installed on the upper side of the rectangular plate 31, and the movable end of the stripping cylinder 32 is provided with a stripping cylinder 32. The arc plate 33, the circular hole is located on the movement track of the stripping arc plate 33, the rectangular plate 31 is provided with a discharging member 35, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com