Picking and overturning structure, transferring device and a full-automatic picking and conveying device

A technology of inversion structure and transfer device, applied in packaging and other directions, can solve the problems of weak adhesion, high equipment cost, unfavorable integrated manufacturing of automated production lines, etc., to achieve a simple and convenient film taking process, avoid post-folding troubles, and realize automatic transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

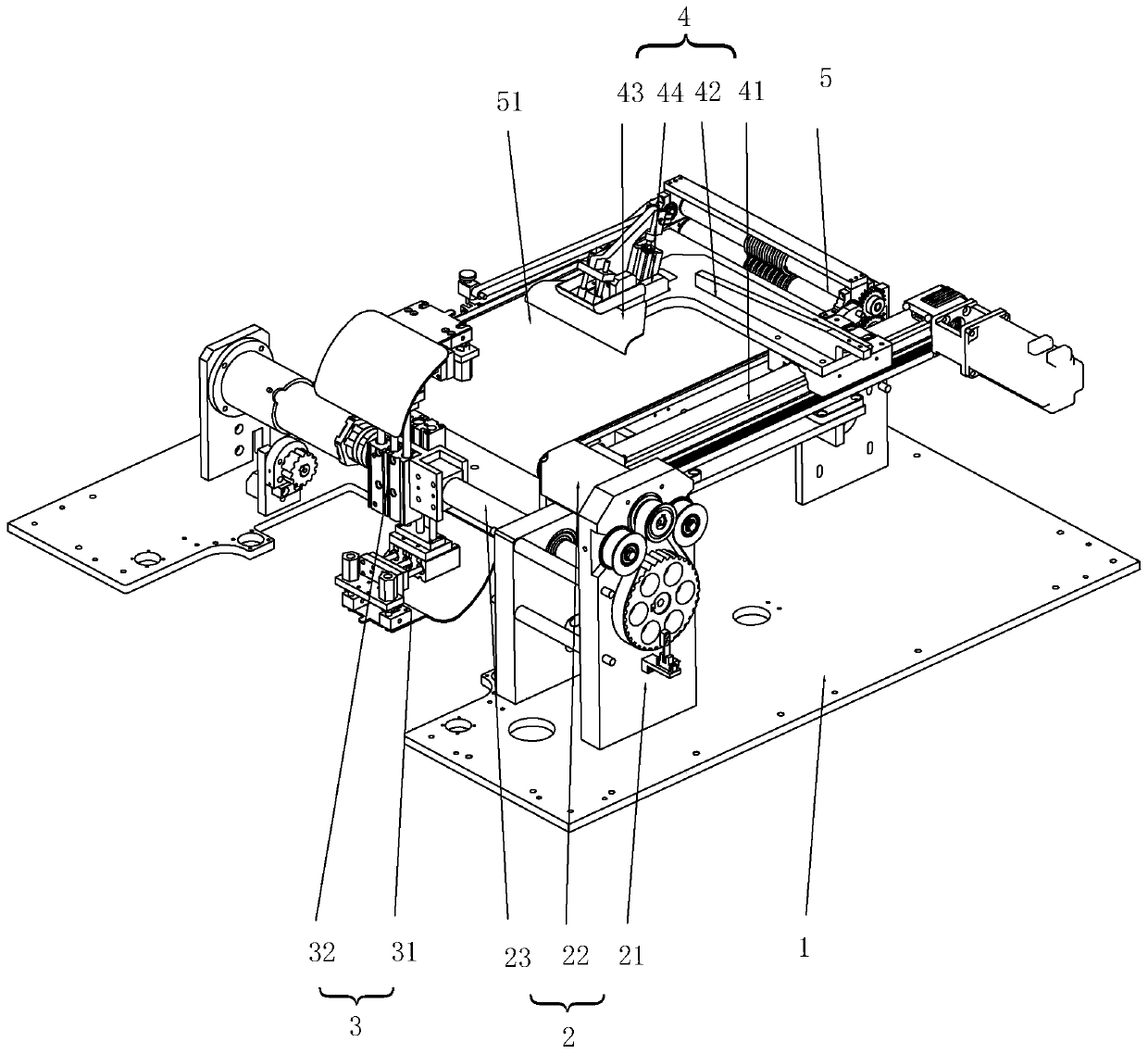

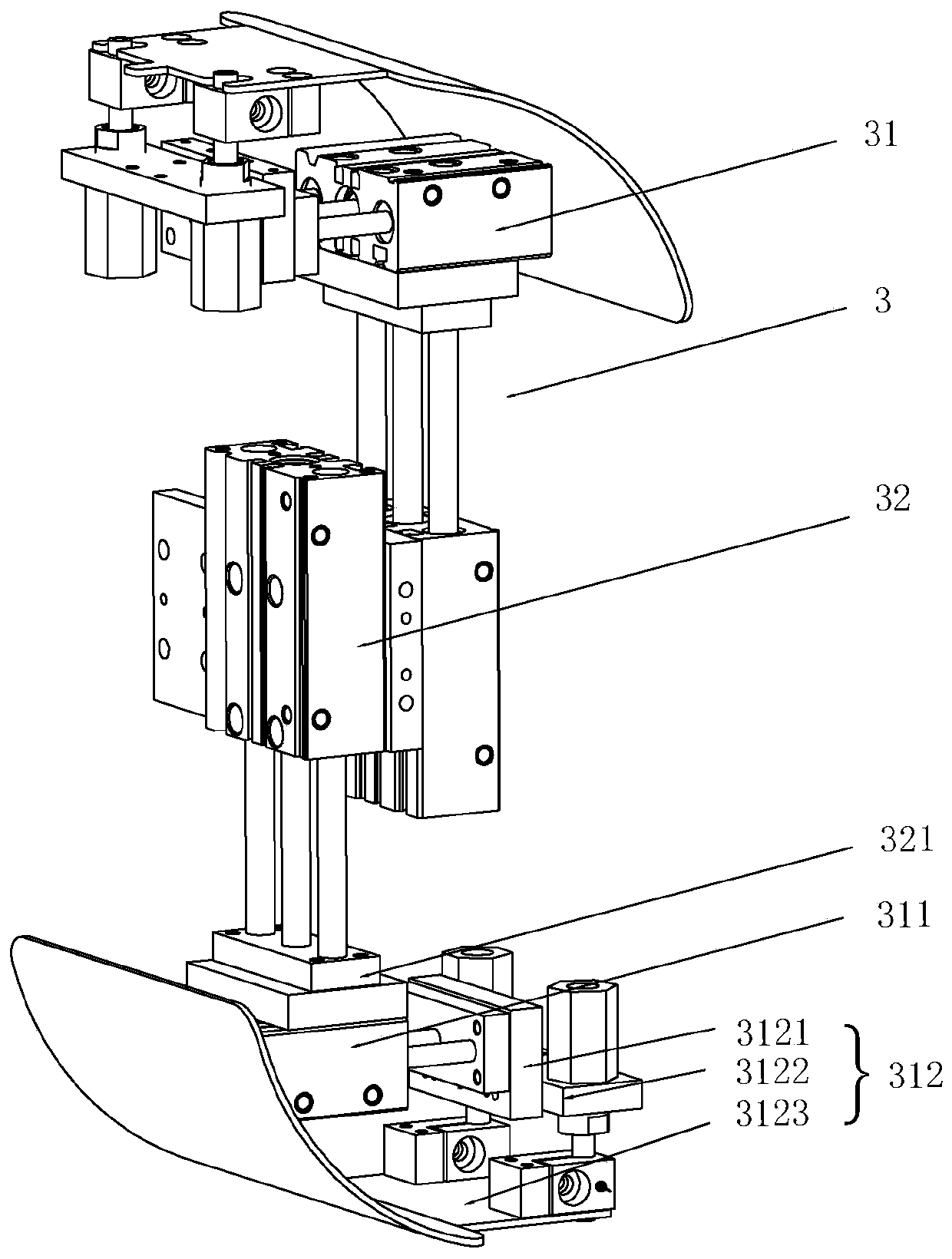

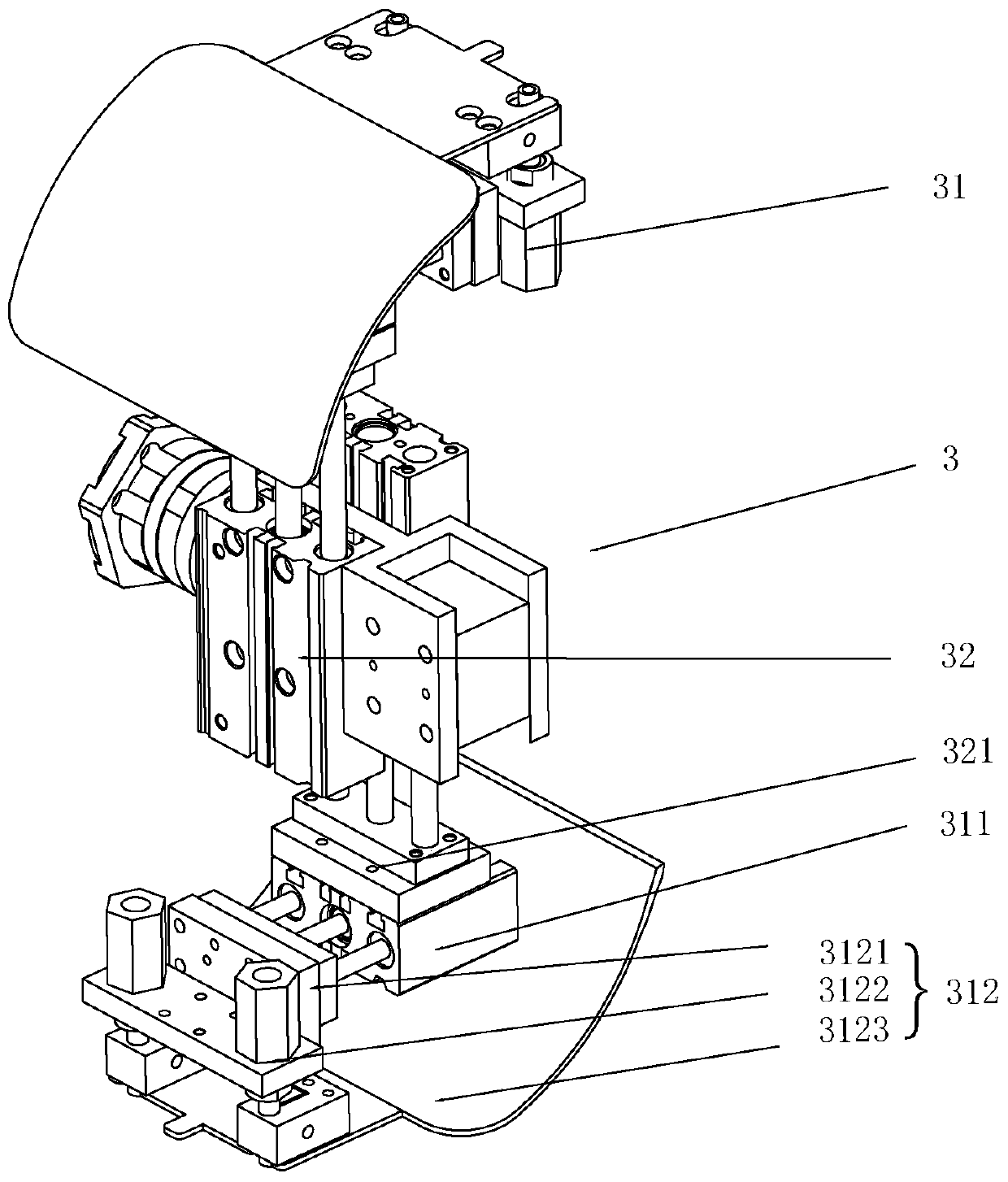

[0027] see Figure 1 to Figure 4 , a reclaiming and turning structure of the present invention, including a base 1, a freely rotatable rotating assembly 2, and a retrieving assembly 3 mounted on the rotating assembly 2, the rotating assembly 2 and the retrieving assembly 3 are installed on the base 1, so The retrieving assembly 3 is provided with at least one group of rubbing mechanisms 31, the number of rubbing mechanisms 31 and the setting of the installation positions can be designed and selected according to the movement efficiency, and the movement balance of the rotating assembly 2 must also be considered. The pick-up assembly 3 can drive the rubbing mechanism 31 to expand and contract in a direction parallel to the radial direction of the rotating assembly 2; the rubbing mechanism 31 can drive the workpieces to reciprocate along the direction of the stacking plane of the workpieces. Among them, in order to better take the film and adapt to different heights of workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com