Discharging mechanical arm of mechanical hand device

A mechanical arm and manipulator technology, applied in the field of robotics, can solve the problems of time-consuming and laborious, high labor cost, and hidden safety hazards of manual handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

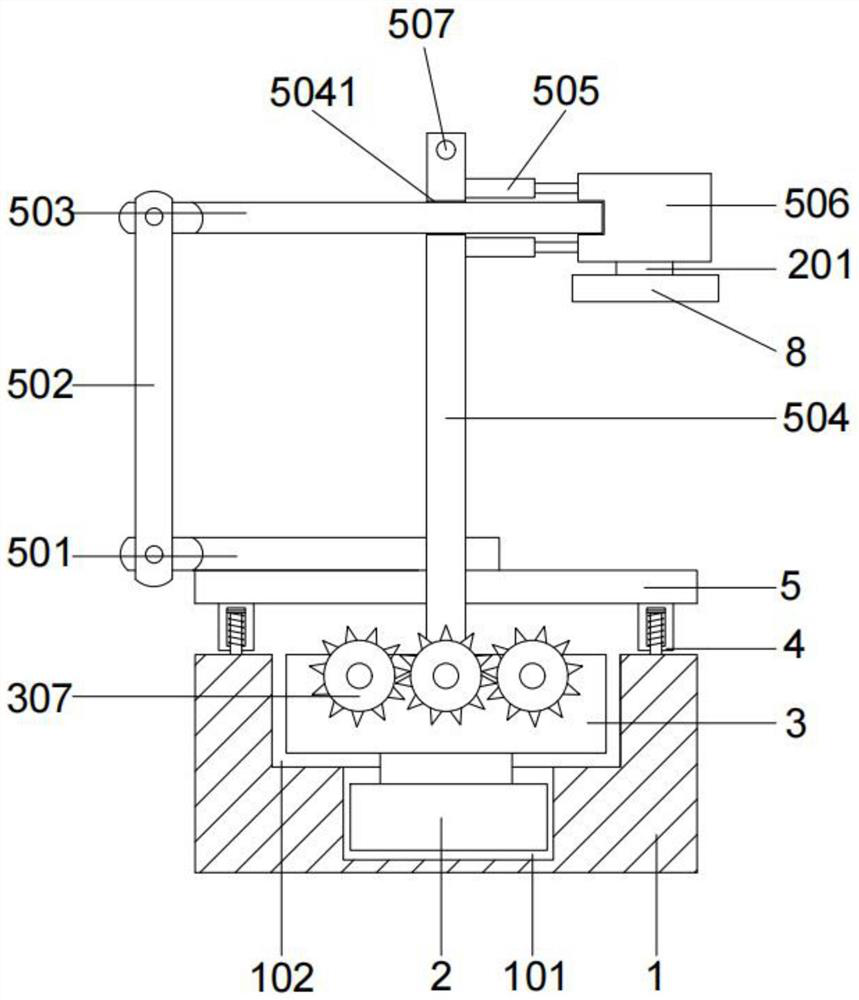

[0037] The embodiment of the present invention provides a kind of unloading robot arm of manipulator device, such as figure 1 As shown, the power base 1 is included, and the left and right sides of the upper end of the power base 1 are symmetrically provided with a shock absorbing mechanism 4, and the middle part of the upper end of the power base 1 is provided with an adjustment cavity 102, and the shock absorbing mechanism 4 is connected with a mechanical arm mechanism. The mechanical arm mechanism includes a guiding mechanism and a clamping mechanism 8, the guiding mechanism is connected with the clamping mechanism 8 through a motor two 201, and an angle adjusting mechanism is arranged inside the adjustment chamber 102, and the angle adjusting mechanism is connected with a guide Mechanism, the electrical components in the power base 1, the mechanical arm mechanism, the clamping mechanism 8 and the angle adjustment mechanism are connected with a control part, and the control ...

Embodiment 2

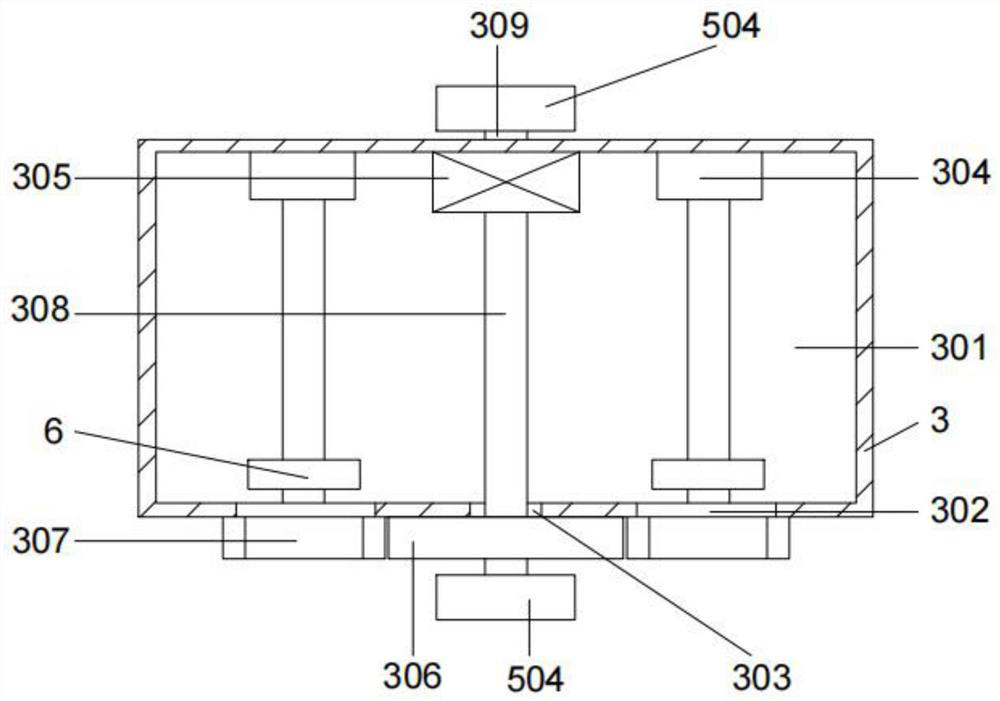

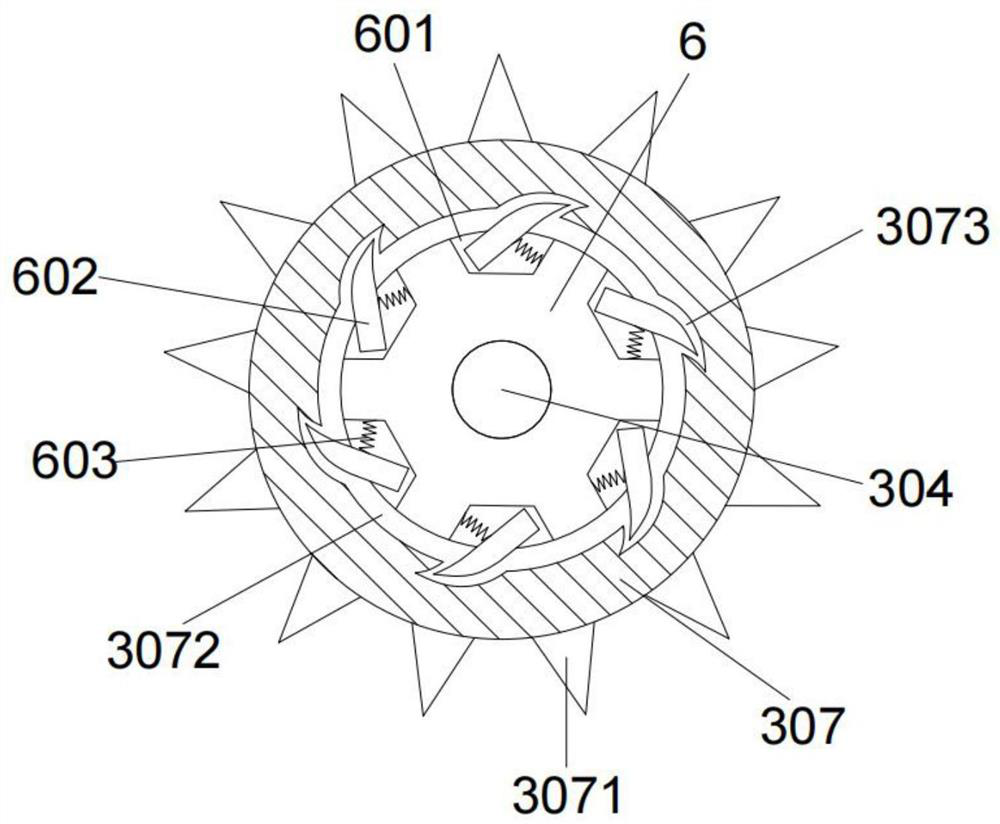

[0041] On the basis of above-mentioned embodiment 1, as Figure 2-Figure 3 As shown, the angle adjustment mechanism includes a working shell 3, the inside of the working shell 3 is provided with a working chamber 2 301, and the left and right sides of the front end of the working shell 3 are provided with an opening 302. The middle part of the front end is provided with an opening 2 303, and the opening 302 communicates with the working chamber 2 301. The left and right sides of the rear end of the working chamber 2 301 are symmetrically provided with an electric telescopic rod 1 304, and the electric telescopic rod 1 304 The front end is fixedly connected with an adjustment balance mechanism, and the middle part of the rear end of the working chamber 2 301 is fixedly provided with a motor 3 305, and the motor 3 305 is fixedly connected with a fixed shaft 308, and the fixed shaft 308 passes through the opening 2 303 is fixedly connected with gear 1 306, and the left and right ...

Embodiment 3

[0046] On the basis of Example 2, such as figure 1 , Figure 4 As shown, the inside of the power base 1 is provided with a working chamber 101, and the working chamber 101 communicates with the adjustment chamber 102 up and down, and the inside of the working chamber 101 is fixed with a motor 2. The fixedly connected motor shaft is fixedly connected with the working shell 3 in the angle adjustment mechanism.

[0047] The shock absorbing mechanism 4 includes a shock absorbing shell 401, which is slidably connected with the guide mechanism. The shock absorbing shell 401 is provided with a buffer cavity 402 inside, and the lower end of the shock absorbing shell 401 is provided with a Opening 3 403, the inside of the buffer chamber 402 is slidingly provided with a buffer plate 404, the buffer plate 404 is fixedly connected with the buffer block 406, the buffer block 406 is sleeved with a spring 2 405 and the spring 2 405 is fixed on the buffer plate Between 404 and the buffer ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com