Conveying device on automated production line

A conveying device and production line technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of high cost, low work efficiency, long construction line, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

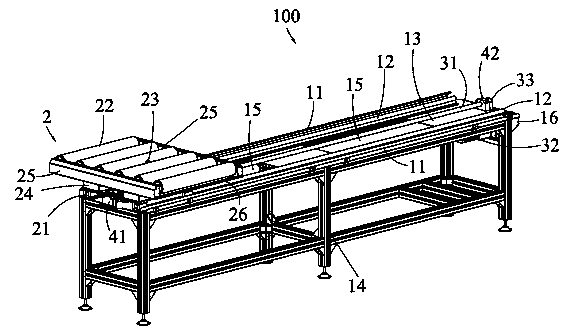

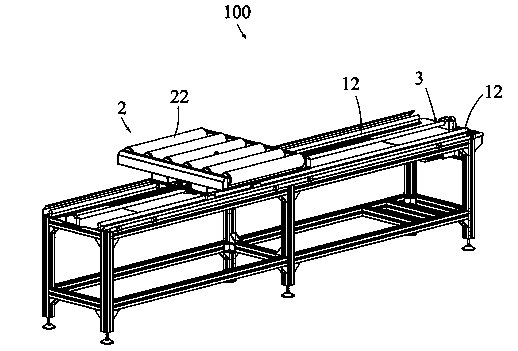

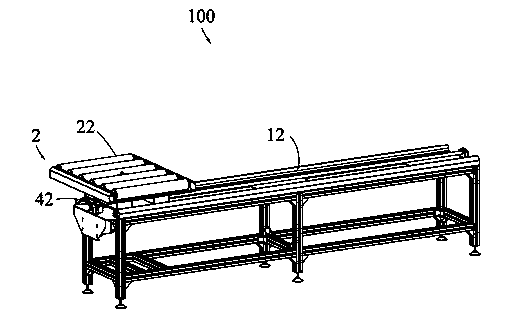

[0021] See figure 1 , Figure 4 , the automatic assembly line conveying device 100 in an embodiment of the present invention is used to transfer finished products (not shown). The conveying device 100 of the automatic assembly line includes a frame body 1 , a tray 2 arranged on the frame body 1 , and a translational driving device 3 for driving the tray 2 to move.

[0022] The frame body 1 includes a flat plate portion 13 placed in parallel, a support portion 14 for supporting the flat plate portion 13, a guide rail 12 arranged on the flat plate portion 13 and extending in the longitudinal direction, and a guardrail arranged at least on one side of the outer periphery of the guide rail 12 11. In this embodiment, there are two guard rails 11 , which are respectively arranged on opposite sides of the periphery of the guide rail 12 . The tray 2 is arranged on the guide rail 12 and the tray 2 is moved along the guide rail 12 by the translation driving device 3 . The guard rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com