Silicon wafer transshipment and loading device and silicon wafer transshipment and loading method based on same

A loading device and transfer device technology, which is applied in transportation and packaging, photovoltaic power generation, electrical components, etc., can solve problems such as automatic loading and unloading, and achieve automatic transfer, reduce damage rate, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

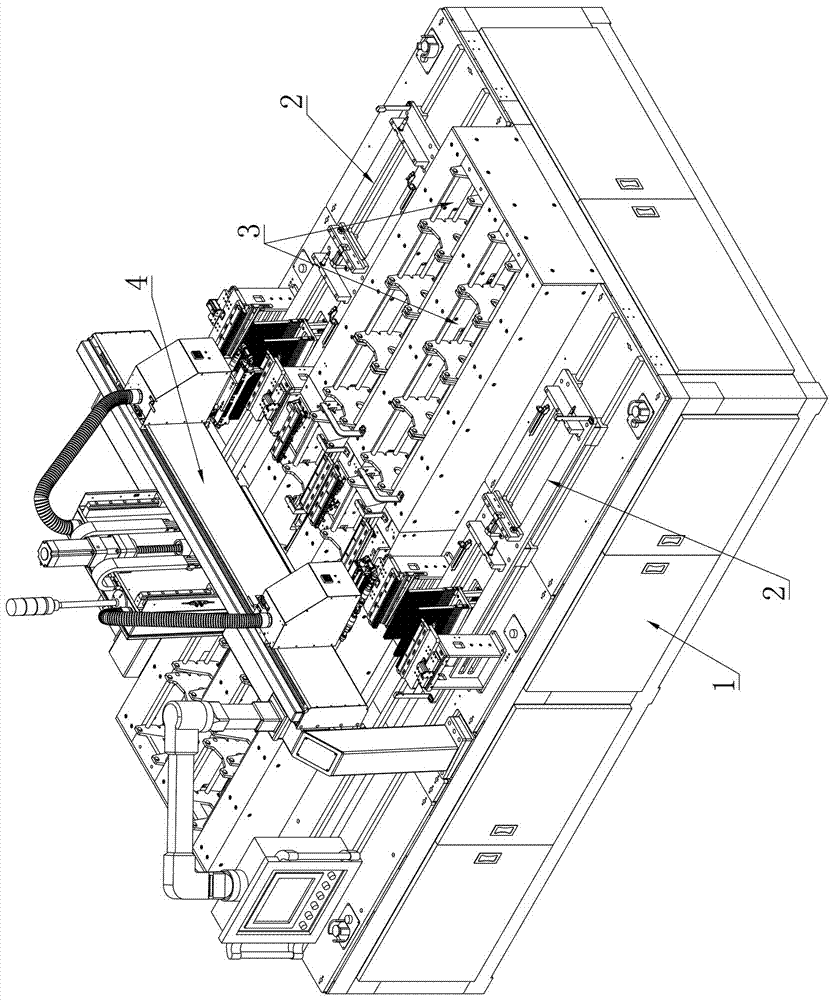

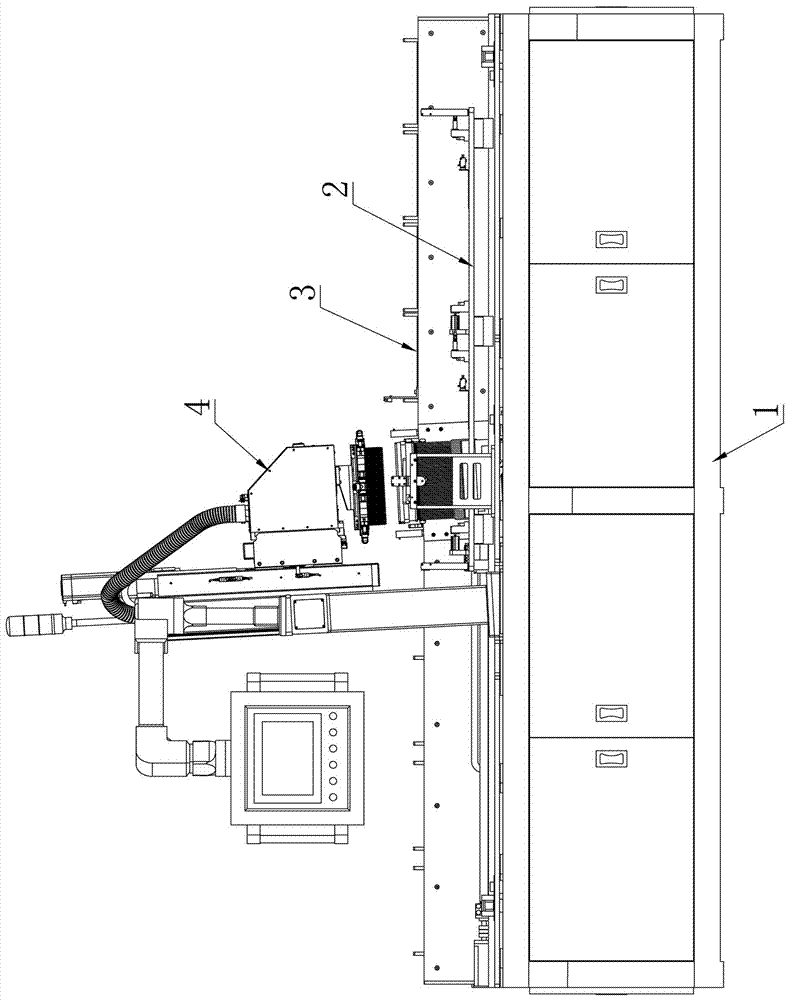

[0036] Such as Figure 1-10 A silicon wafer transfer loading device is shown, which includes a frame 1, two quartz boat positioning loading and unloading systems 2, a flower basket channel transfer system 3 and a double-head transfer manipulator system 4; the two quartz boat positioning loading and unloading systems 2 are respectively It is arranged on the left and right sides of the frame 1, the flower basket channel transfer system 3 is arranged in the middle of the frame 1 and is located between the two quartz boat positioning loading and unloading systems 2, and the double-head transfer manipulator system 4 is horizontal It straddles the left and right sides of the frame 1 and is located above the quartz boat positioning loading and unloading system 2 and flower basket channel transfer system 3 .

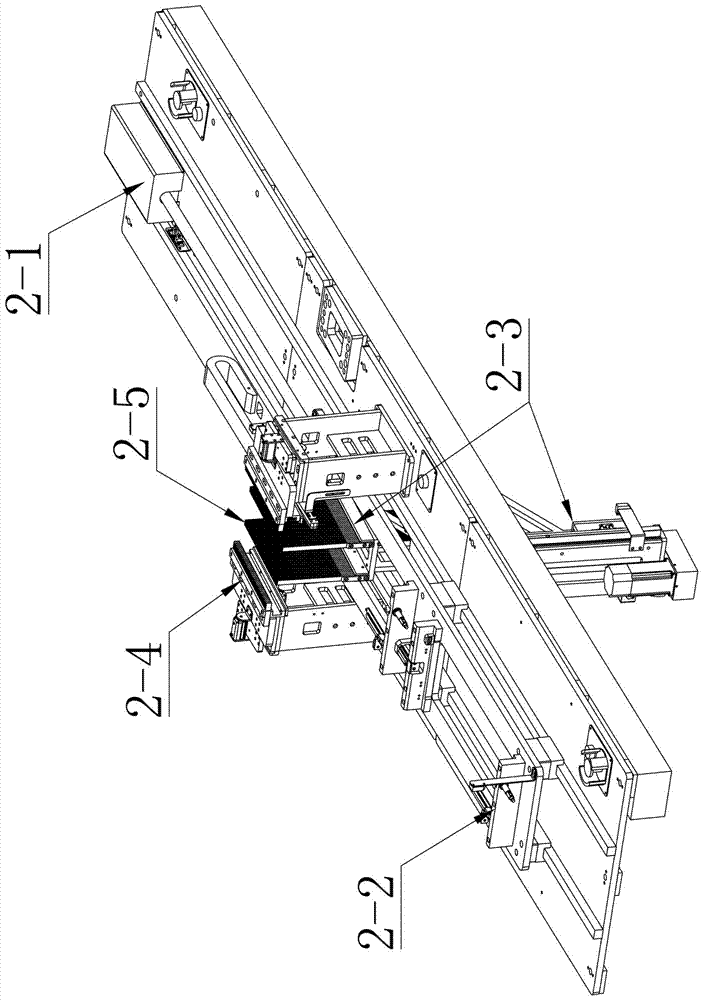

[0037] Such as figure 2 As shown, the quartz boat positioning loading and unloading system 2 includes a quartz boat horizontal movement mechanism 2-1, a quartz boat positionin...

Embodiment 2

[0046] A silicon wafer diffusion transfer loading method based on the silicon wafer transfer loading device described in Embodiment 1, the groove spacing of the quartz boat is 2.38mm, and the groove spacing of the flower basket is 4.76mm; the ordinary boat has 200 grooves and can hold 200 pieces ; The big boat has 500 slots and can hold 500 pieces; the flower basket has 50 slots and can hold 50 pieces.

[0047] Proceed as follows:

[0048] The silicon chips are transferred from the flower baskets to the quartz boat: place the two flower baskets containing the silicon chips in the two flower basket channels 3-1 respectively, and place the two flower baskets one positive and one reverse; A quartz boat is placed on the loading and unloading system, and the quartz boat horizontal movement mechanism 2-1 transports the quartz boat to the middle, and is positioned by the quartz boat positioning mechanism 2-2; under the action of the transfer device in the flower basket channel, the f...

Embodiment 3

[0052] A silicon wafer annealing transfer loading method based on the silicon wafer transfer loading device according to claim 1, characterized in that the steps are as follows: the groove spacing of the quartz boat is 2.38mm, the groove spacing of the flower basket is 4.76mm; the ordinary boat is 200 The one with 50 slots can hold 200 pieces; the one with 500 slots can hold 500 pieces; the flower basket with 50 slots can hold 50 pieces.

[0053] Silicon chips are transferred from flower baskets to quartz boats: place the two flower baskets containing silicon chips on the feeding section 301 in the two flower basket channels 3-1 respectively; position the loading and unloading system 2 on the two quartz boats The quartz boats are respectively placed on the top, and the quartz boat horizontal movement mechanism 2-1 transports the quartz boats to the middle, and is positioned by the quartz boat positioning mechanism 2-2; under the action of the transfer device in the flower baske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com