Plastic bag tidying device

A sorting device and technology of plastic bags, which are applied in the directions of packaging, bag making, transportation and packaging, can solve the problems of high labor intensity, low efficiency of collecting and sorting packaging bags, high labor costs, and achieve the effect of regular length direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

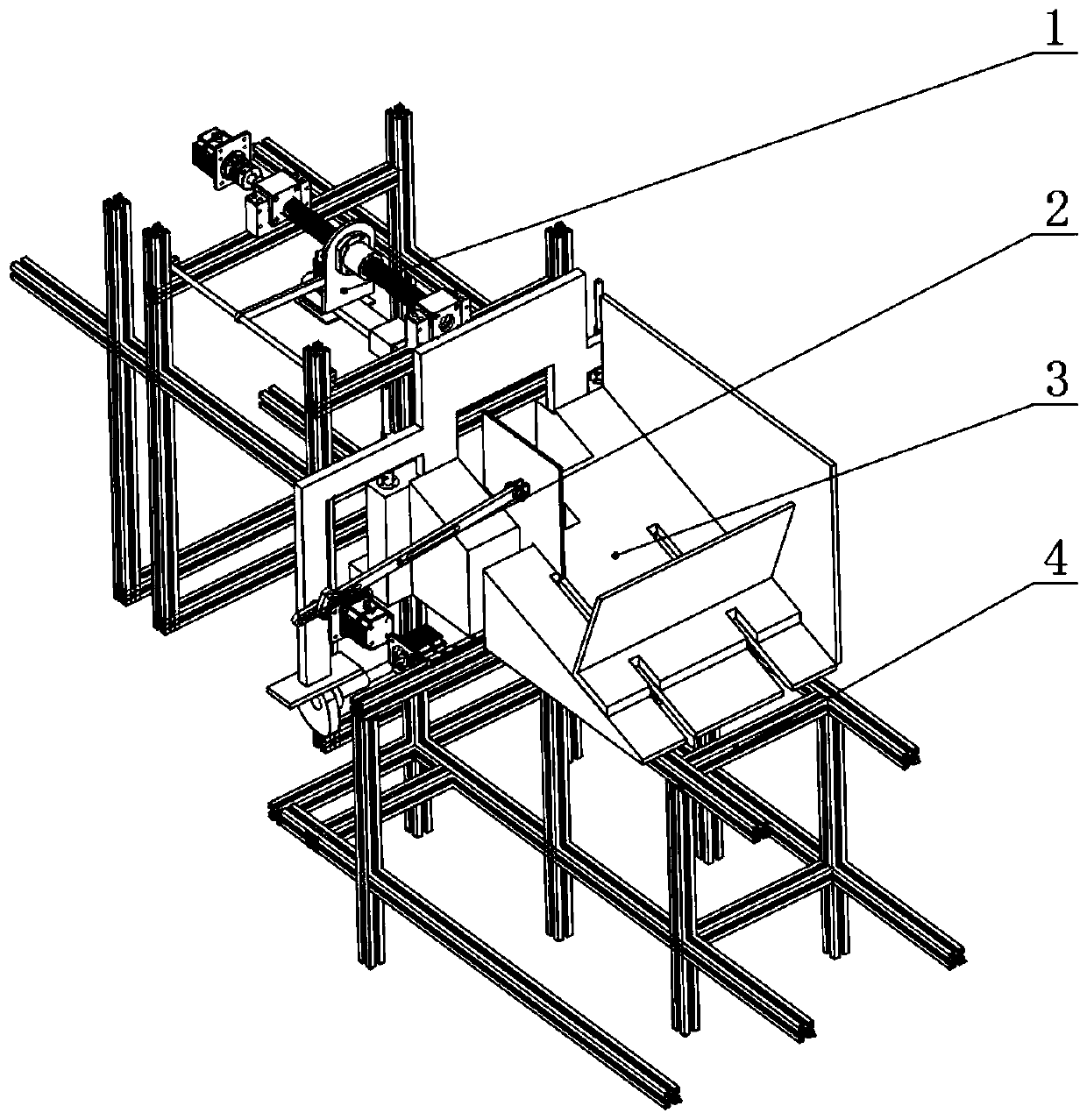

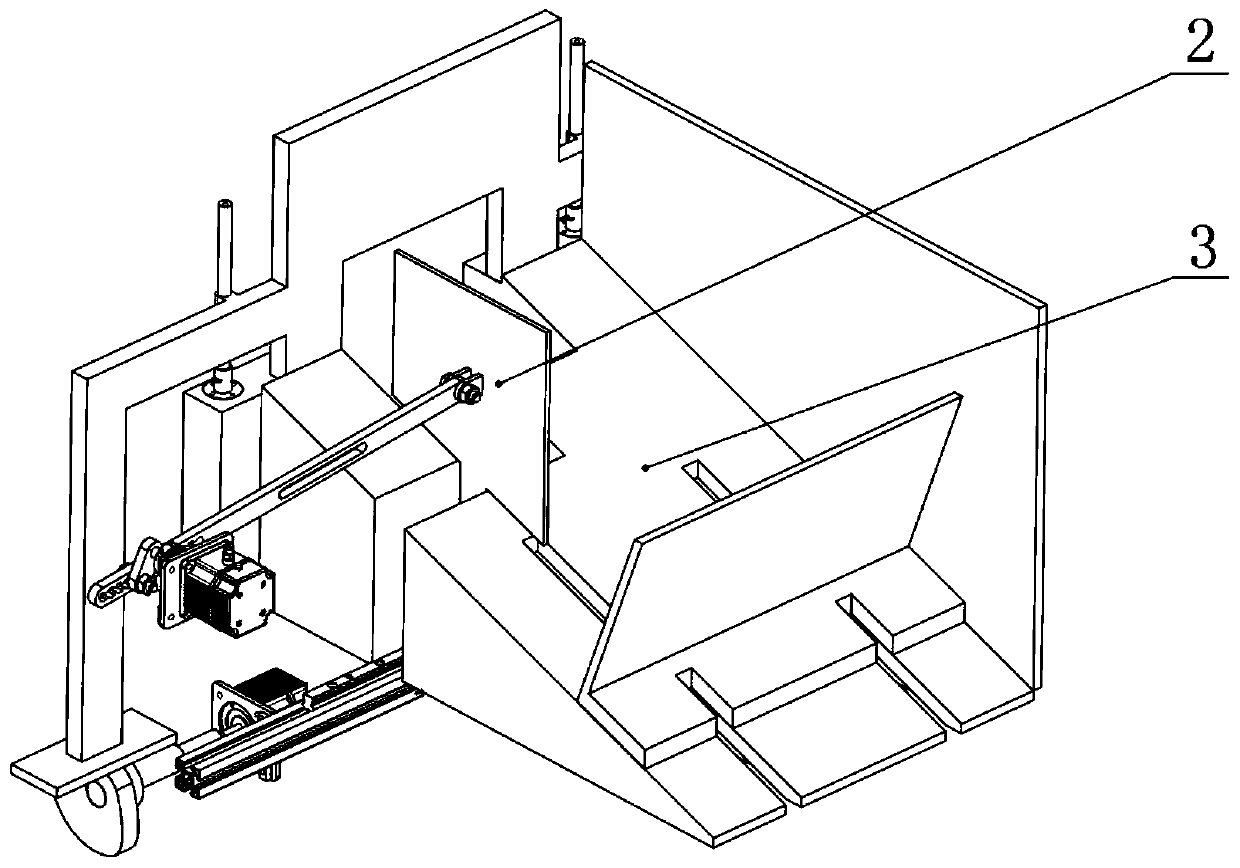

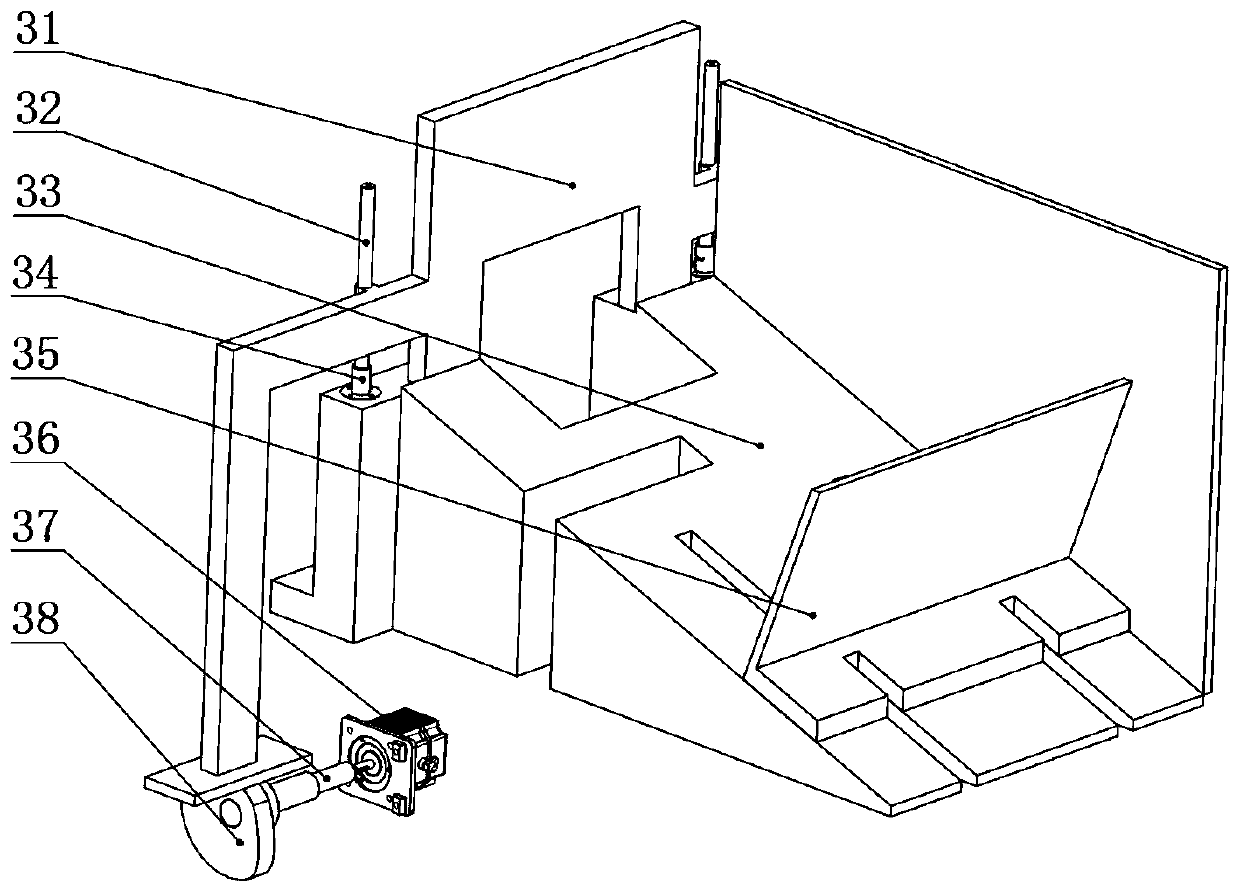

[0027] Such as Figure 1-9 Shown, a kind of plastic bag sorting device of the present invention, wherein figure 1 It is a schematic diagram of the overall structure of the plastic bag sorting device, which is composed of a transfer device 1, a sorting device 2, a collecting device 3, and a frame 4. According to the model size of plastic bag, rationally adjust the distance from rear baffle plate 35 to front portion baffle plate 31. When the plastic bag is flatly thrown on the rear baffle 35 with a certain initial speed from the high-speed bag making machine, it will fall into the collection device 3 due to gravity, thereby realizing the regularity of the plastic bag in the length direction. At this time, the second motor 28 in the finishing device 2 starts, and its output shaft is connected with the crankshaft 26 through the first coupling 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com