Slip driving-based curved surface adaptive all-round omni-directional wall climbing robot

A wall-climbing robot, self-adaptive technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of poor flexibility, poor safety, and poor obstacle-crossing performance of robots, achieve strong movement flexibility and passability, and improve operation The effect of efficiency and strong surface adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

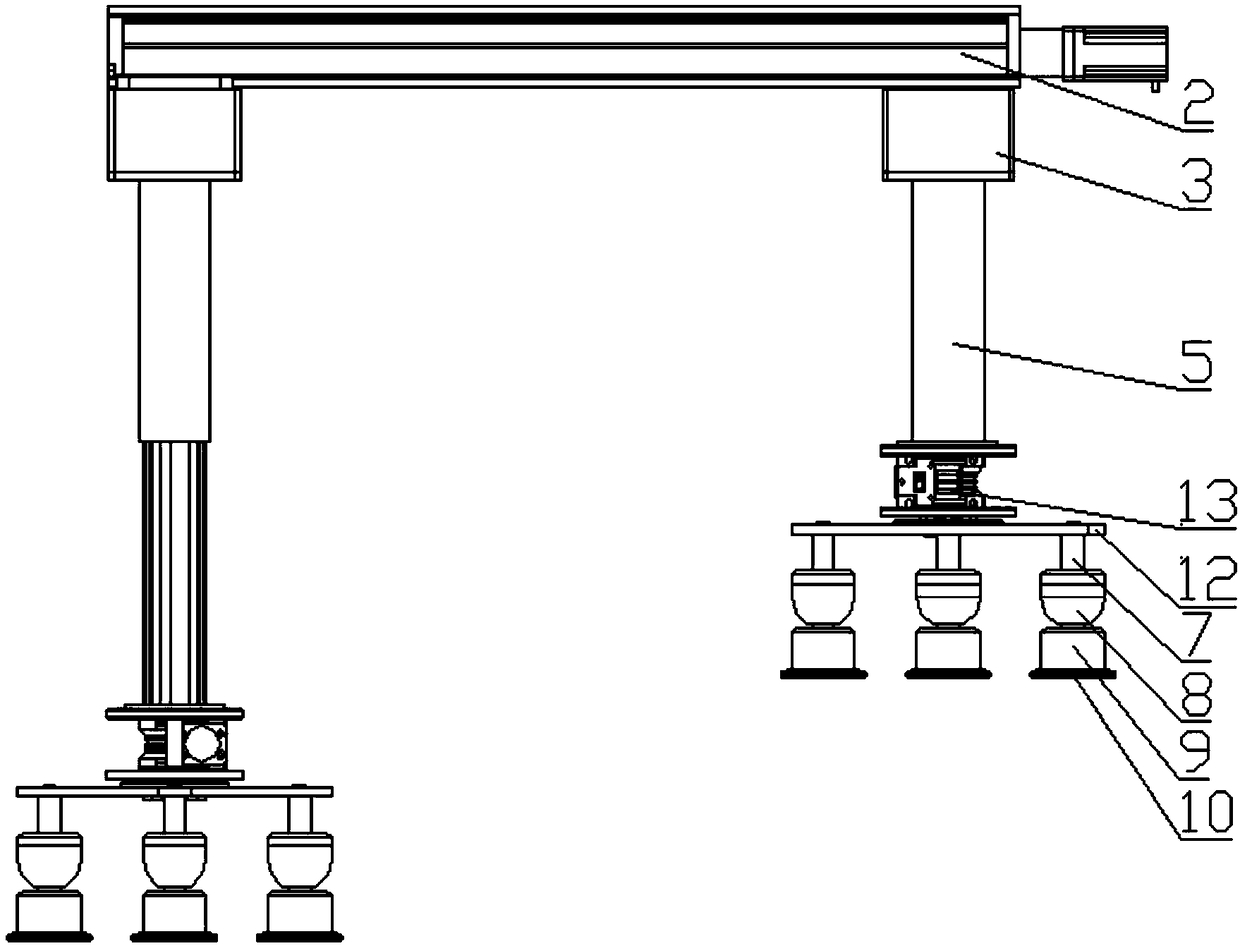

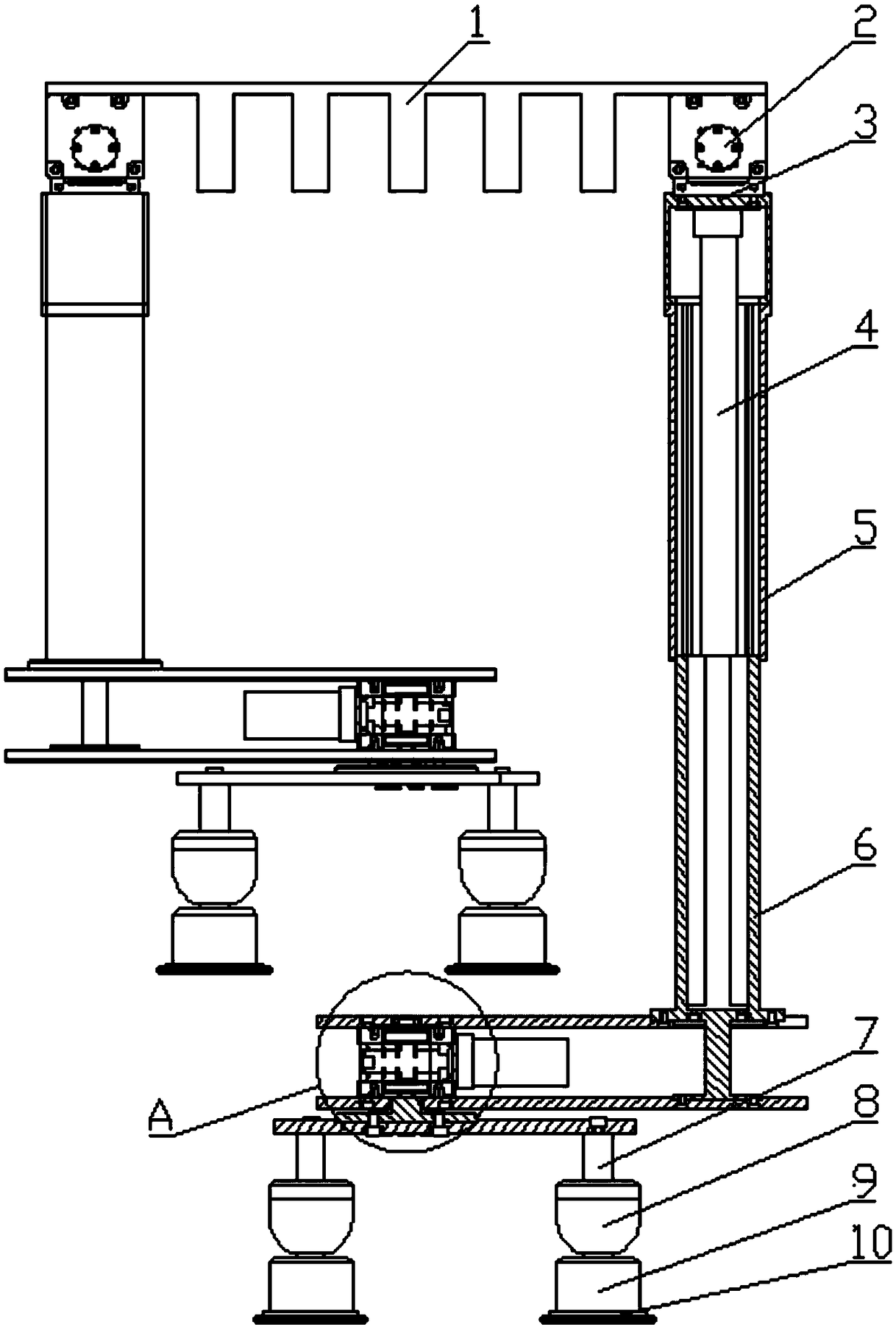

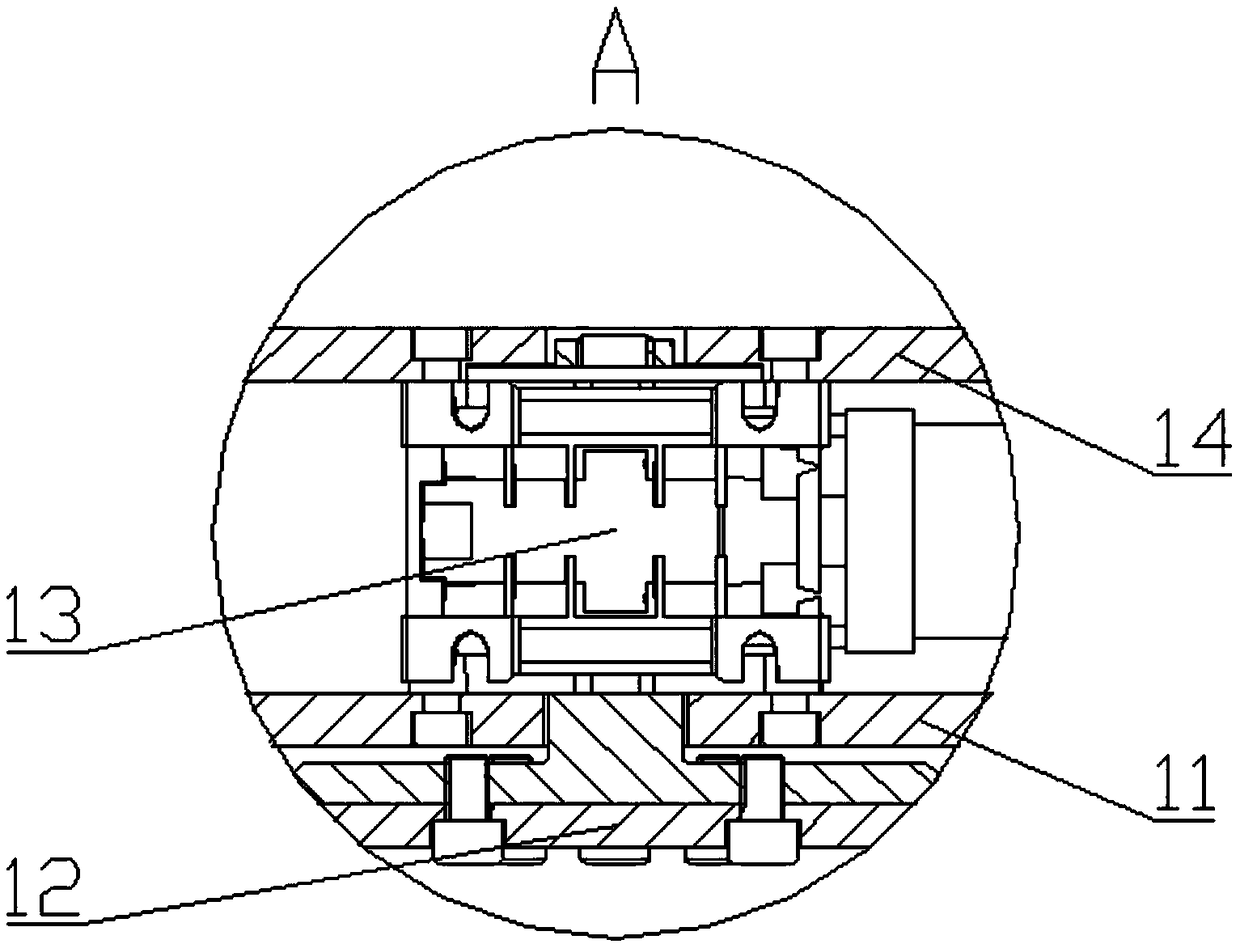

[0026] The invention provides a curved surface self-adaptive all-round wall-climbing robot based on sliding drive (referred to as robot, see Figure 1-6 ), including a trunk and two mechanical legs; the two mechanical legs are installed on the trunk, and the trunk is used to realize the sliding drive of the two mechanical legs; each mechanical leg includes a feed mechanism, a rotating mechanism and at least three automatic Adaptive curvature adsorption mechanism; the adaptive curvature adsorption mechanism is in flexible contact with the working surface, the rotation mechanism drives the trunk to turn, and the feed mechanism makes the two mechanical legs move forward alternately; it is characterized in that the trunk includes a moving platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com