Low-pressure casting motor shell spiral waterway sand core cleaning machine and operating method thereof

A motor casing and low-pressure casting technology, which is applied in the field of low-pressure casting motor casing spiral channel sand core cleaning machines, can solve problems such as time-consuming and labor-intensive, affecting production efficiency, and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and examples.

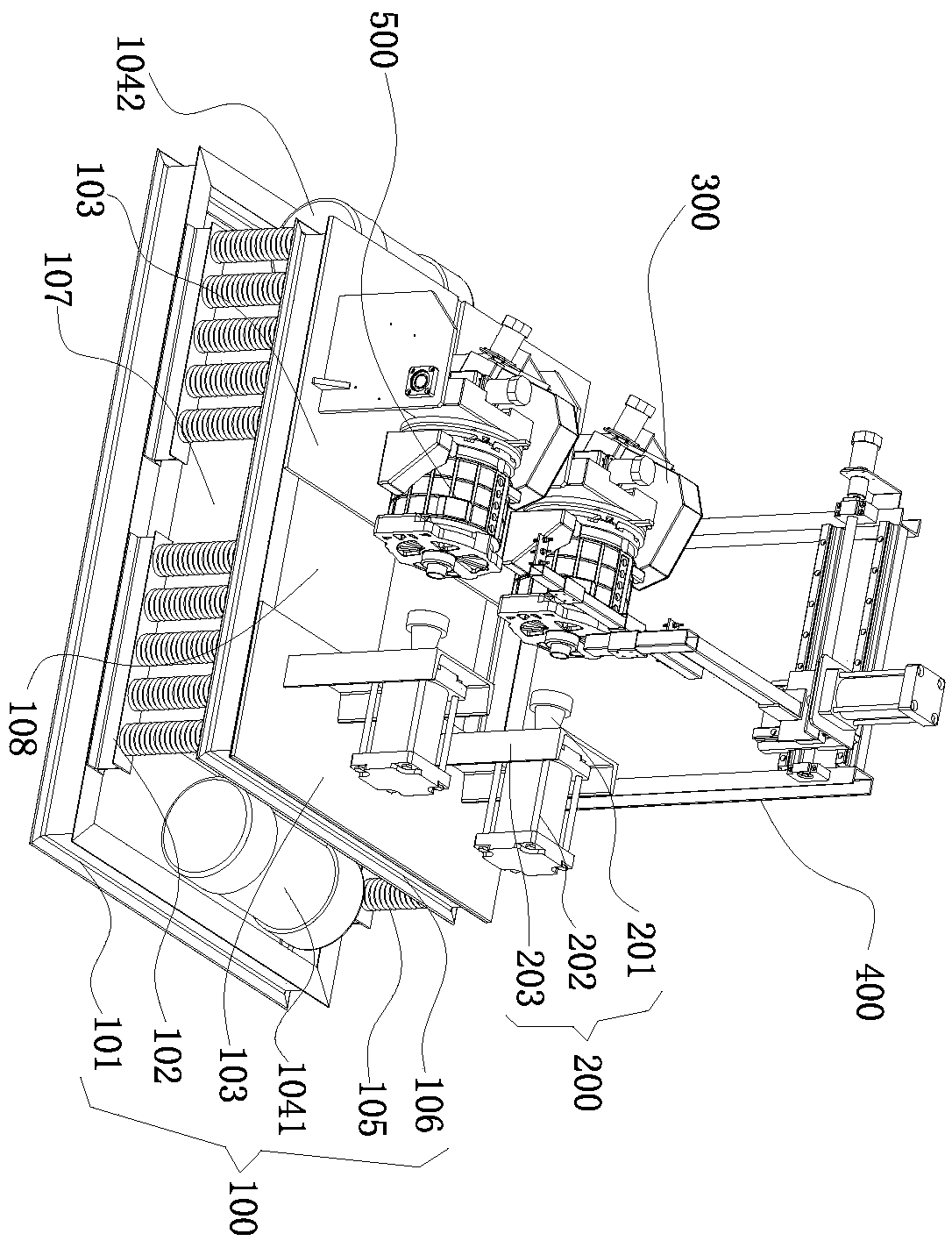

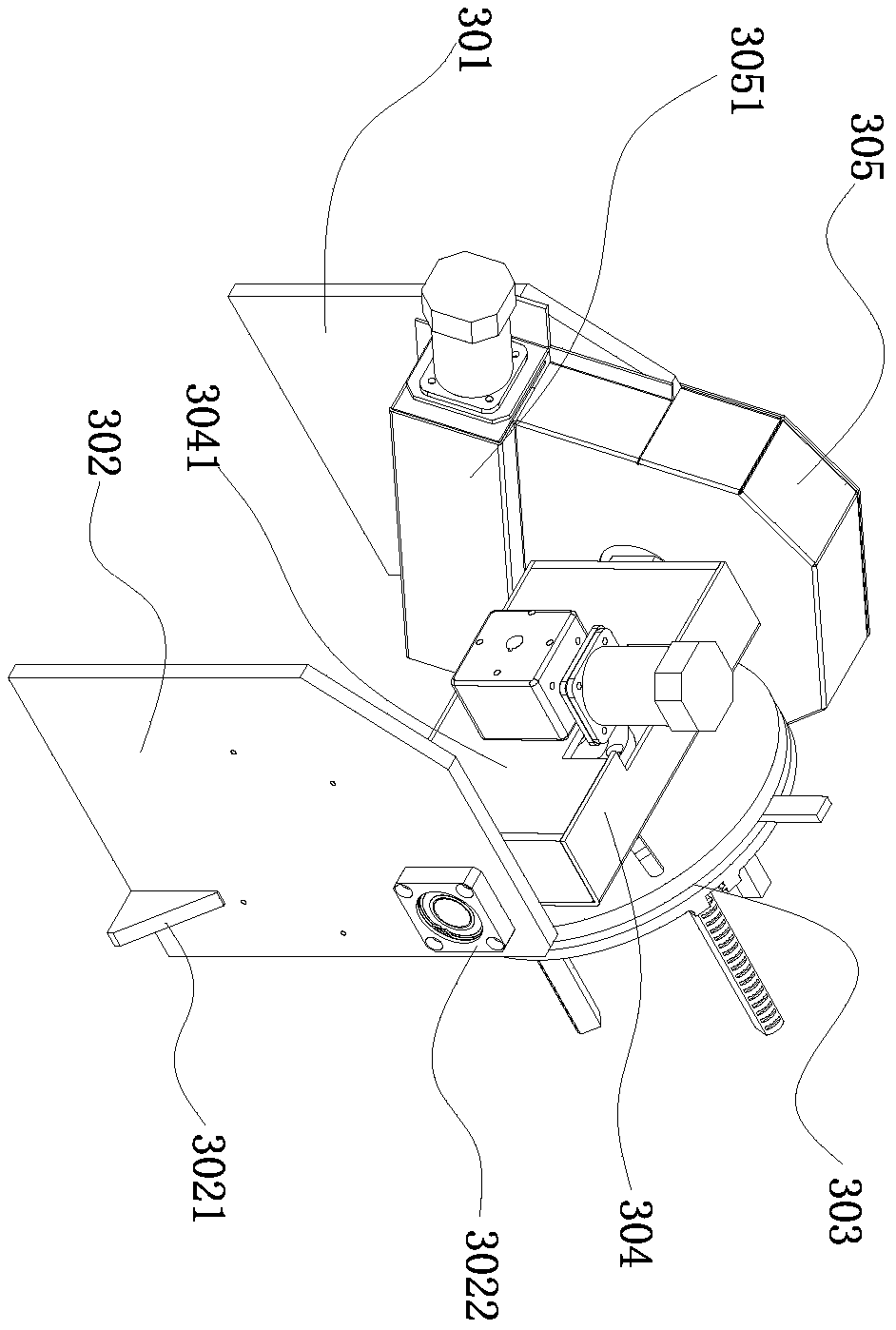

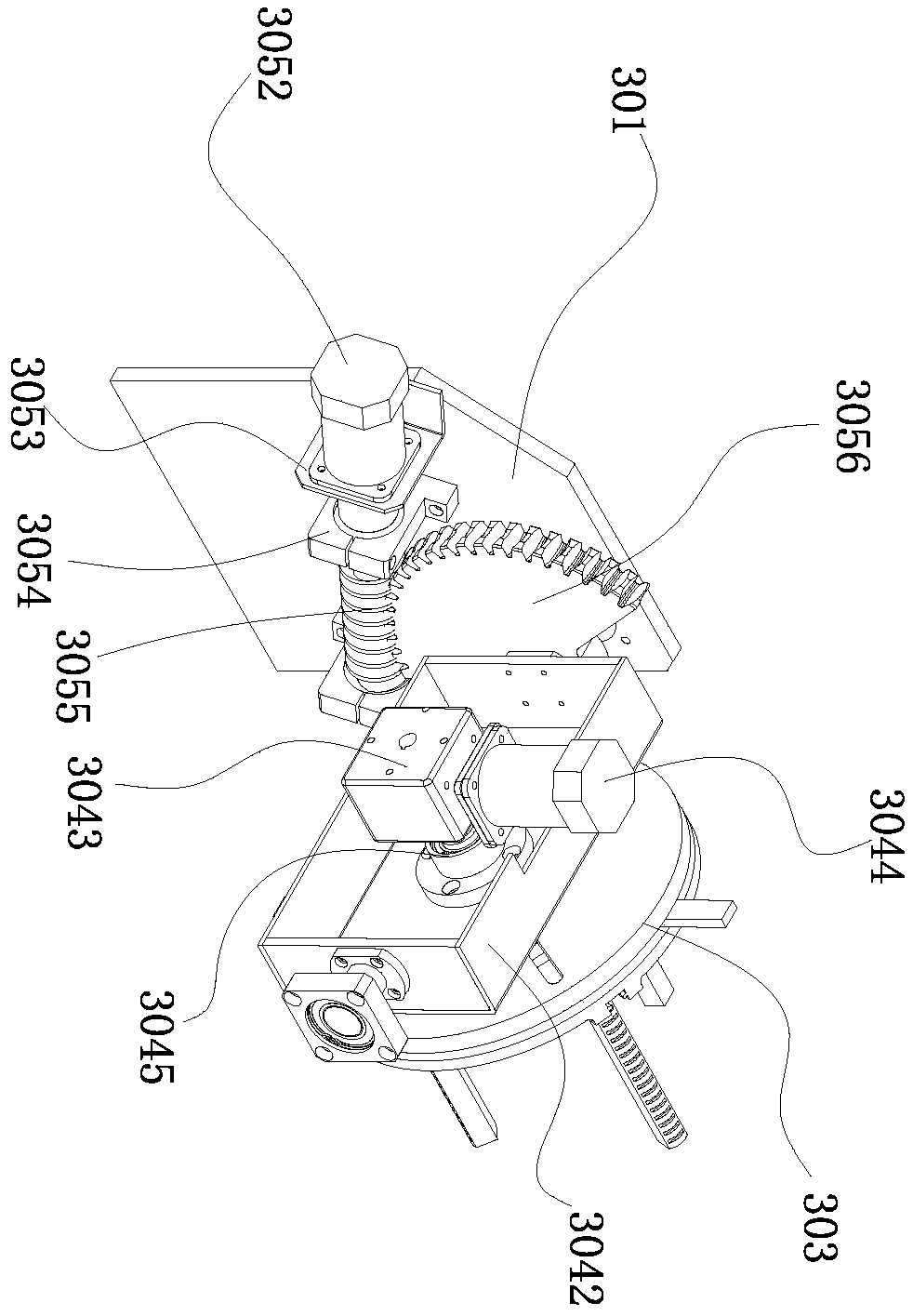

[0031] like figure 1 and Figure 4 As shown, the low-pressure casting motor housing spiral waterway sand core cleaning machine includes a vibrating table module 100, a flipping and rotating module 300, a compacting module 200 and a pneumatic sand washing module 400. The vibrating table module 100 includes an I-beam base 101, an I-beam upper seat 106 and sand storage sheet metal box 107, several I-beams 102 are arranged on I-beam base 101, and some compression springs 105 are installed on every I-beam 102; There are 4 I-beams, and each I-beam is equipped with 5 compression springs; the I-beam upper seat 106 is fixedly installed on the compression spring 105, and the sand storage sheet metal box 107 is installed on the I-beam base 102 and the I-shaped steel upper seat 106, the sand storage sheet metal box 107 is fixedly welded to the bottom of the I-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com