Printing and dyeing system capable of adjusting multiple colors

A kind of dye and blue technology, applied in the field of new multi-color adjustable printing and dyeing system, can solve the problems of single color of fabrics, lack of beauty and artistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

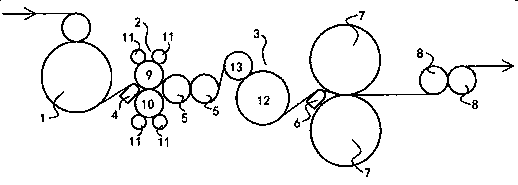

[0034] A multi-color adjustable printing and dyeing system, including multiple dyeing devices and heating rollers, characterized in that the dyeing device includes a red dyeing unit 1, a blue dyeing unit 2, a green dyeing unit 3, a red dyeing unit 1 and a blue dyeing unit The first heating rod 4 is arranged between the 2, the heating roller 5 is arranged between the blue dyeing part 2 and the green dyeing part 3, the second heating rod 6 and the color fixing roller 7 are arranged behind the blue dyeing part 2, and the color fixing A heating and shaping roller 8 is arranged behind the roller 7 . The first heating rod 4 and the second heating rod 6 carry out appropriate preliminary heating and drying on the fabric after the previous dyeing, so as to facilitate the subsequent processing; the color fixing roller 7 squeezes out the excess dye on the fabric and removes it The floating color plays a role in fixing the color.

[0035] The fabric is dyed with the yellow, blue and gree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com